FTECH 3310 Food Engg Lecture 1.pptx

•Download as PPTX, PDF•

1 like•111 views

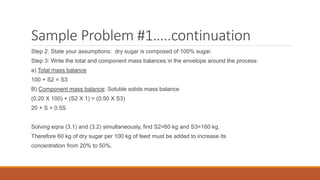

The document contains 3 sample problems involving mixing, evaporation/mixing, and concentration processes. In sample problem 1, mass balances are used to determine that 60 kg of dry sugar must be added to 100 kg of 20% sugar solution to increase the concentration to 50%. Sample problem 2 involves evaporating orange juice to 60% concentration, mixing it with fresh juice to obtain 42% concentration. Mass balances show 8000 kg/h of water must evaporate, 1200 kg/h of fresh juice added, producing 3200 kg/h of final product. Sample problem 3 freezes and separates fruit juice, with mass balances indicating 750 kg/h of ice is removed and 250 kg/h of 40% concentrated juice is produced.

Report

Share

Report

Share

Recommended

Fluid energy mill for pharmacy principles, construction, working, uses, meri...

this is an slideshare for pharmacy students, principles, construction, working, uses, merits and

demerits of , fluid energy mill its for b. pharm. and M. PHARM

Sigma blade mixer

The sigma blade mixer consists of a double trough shaped stationary bowl with two sigma shaped blades fitted horizontally in each trough. The blades are connected to a fixed speed drive and rotate to create high shear and kneading actions through their intermeshing motion. Powders are introduced into the trough from the top and the body is covered during mixing to prevent dust or evaporation. The sigma blade mixer is commonly used for mixing dough ingredients through its ability to thoroughly blend materials with minimal dead space at a fixed speed.

Anti P

This document discusses the treatment of psychotic disorders with antipsychotic drugs. It begins by defining psychotic disorders and their characteristics. It then describes major psychotic disorders and historical treatments prior to drugs such as shock therapy. It introduces the first antipsychotic drug, chlorpromazine, and describes the mechanisms and side effects of two classes of antipsychotic drugs: phenothiazines and butyrophenones. Finally, it discusses atypical antipsychotics which have fewer side effects, and current and future research directions for improving antipsychotic treatment.

Lyophlization & Elutriation

The document discusses lyophilization and elutriation. Lyophilization, or freeze drying, is a process that removes water from a frozen product under vacuum, allowing ice to change directly to vapor without passing through liquid. It involves freezing, primary drying to remove 98-99% water, and secondary drying to remove remaining bound water. Elutriation separates particles based on size, shape and density using an opposing gas or liquid stream, allowing finer particles to move upward while larger ones sediment downward.

Drying- Pharmaceutical Engineering

Definition of drying

Importance of drying

Difference between drying and evaporation

Drying is defined as removal of the liquid from a material by application of heat & is accomplished by transfer of a liquid from the surface into an unsaturated vapor phase .

Drying is the final removal of water from material (usually by heat)

Drying is commonly the last stage in a manufacture process

Non-thermal drying

1- As Squeezing wetted sponge

2- Adsorption by desiccant (desiccation)

3- Extraction.

Preservation of drug products

Preparation of bulk drugs

Improved handling

Improved characteristics

Equipments

Drying is necessary in order to avoid deterioration. A few examples are…

--blood products, tissues… undergo microbial growth

--effervescent tablets, synthetic & semi synthetic drugs undergo…. chemical decomposition.

Production of styrene

This document is a declaration form for a thesis submitted by five students - Abubakar Saleem, Muhammad Noman Saeed, Irfan Riaz, Umair Shoaib, and Muhammad Humza. The thesis is titled "A Plant Design Report on Production of 100,000 MTPY of Styrene from Dehydrogenation of Ethyl benzene". The declaration form certifies that the thesis is the original work of the students and complies with university policies regarding publishing and copyright. It has been reviewed and approved by the students' supervisor, Dr. Fahad Rehman.

Pharmaceutical engineering: Distillation

This document discusses distillation, which is a process used to separate mixtures based on differences in their boiling points. It defines distillation and provides examples of its applications. It then classifies different types of distillation, including simple distillation, fractional distillation, vacuum distillation, and molecular distillation. For each type, it provides a brief overview of the principle, construction, working, and some applications. The document is presented by an assistant professor and provides detailed information on various distillation methods.

Phenanthrene by Mr. pradeep swarnkar

Phenanthrene is a polycyclic aromatic hydrocarbon composed of three fused benzene rings. It appears as a white powder with blue fluorescence. Phenanthrene shows aromatic properties and is the backbone molecule for morphine. It undergoes reactions like oxidation, reduction, bromination, and electrophilic addition or substitution. Derivatives of phenanthrene like papaverine are used as vasodilators to increase blood flow. Phenanthrene and its derivatives have several medicinal uses including manufacturing dyes, acting as antifungals, and being components of steroids, sex hormones, bile acids, and cardiac glycosides.

Recommended

Fluid energy mill for pharmacy principles, construction, working, uses, meri...

this is an slideshare for pharmacy students, principles, construction, working, uses, merits and

demerits of , fluid energy mill its for b. pharm. and M. PHARM

Sigma blade mixer

The sigma blade mixer consists of a double trough shaped stationary bowl with two sigma shaped blades fitted horizontally in each trough. The blades are connected to a fixed speed drive and rotate to create high shear and kneading actions through their intermeshing motion. Powders are introduced into the trough from the top and the body is covered during mixing to prevent dust or evaporation. The sigma blade mixer is commonly used for mixing dough ingredients through its ability to thoroughly blend materials with minimal dead space at a fixed speed.

Anti P

This document discusses the treatment of psychotic disorders with antipsychotic drugs. It begins by defining psychotic disorders and their characteristics. It then describes major psychotic disorders and historical treatments prior to drugs such as shock therapy. It introduces the first antipsychotic drug, chlorpromazine, and describes the mechanisms and side effects of two classes of antipsychotic drugs: phenothiazines and butyrophenones. Finally, it discusses atypical antipsychotics which have fewer side effects, and current and future research directions for improving antipsychotic treatment.

Lyophlization & Elutriation

The document discusses lyophilization and elutriation. Lyophilization, or freeze drying, is a process that removes water from a frozen product under vacuum, allowing ice to change directly to vapor without passing through liquid. It involves freezing, primary drying to remove 98-99% water, and secondary drying to remove remaining bound water. Elutriation separates particles based on size, shape and density using an opposing gas or liquid stream, allowing finer particles to move upward while larger ones sediment downward.

Drying- Pharmaceutical Engineering

Definition of drying

Importance of drying

Difference between drying and evaporation

Drying is defined as removal of the liquid from a material by application of heat & is accomplished by transfer of a liquid from the surface into an unsaturated vapor phase .

Drying is the final removal of water from material (usually by heat)

Drying is commonly the last stage in a manufacture process

Non-thermal drying

1- As Squeezing wetted sponge

2- Adsorption by desiccant (desiccation)

3- Extraction.

Preservation of drug products

Preparation of bulk drugs

Improved handling

Improved characteristics

Equipments

Drying is necessary in order to avoid deterioration. A few examples are…

--blood products, tissues… undergo microbial growth

--effervescent tablets, synthetic & semi synthetic drugs undergo…. chemical decomposition.

Production of styrene

This document is a declaration form for a thesis submitted by five students - Abubakar Saleem, Muhammad Noman Saeed, Irfan Riaz, Umair Shoaib, and Muhammad Humza. The thesis is titled "A Plant Design Report on Production of 100,000 MTPY of Styrene from Dehydrogenation of Ethyl benzene". The declaration form certifies that the thesis is the original work of the students and complies with university policies regarding publishing and copyright. It has been reviewed and approved by the students' supervisor, Dr. Fahad Rehman.

Pharmaceutical engineering: Distillation

This document discusses distillation, which is a process used to separate mixtures based on differences in their boiling points. It defines distillation and provides examples of its applications. It then classifies different types of distillation, including simple distillation, fractional distillation, vacuum distillation, and molecular distillation. For each type, it provides a brief overview of the principle, construction, working, and some applications. The document is presented by an assistant professor and provides detailed information on various distillation methods.

Phenanthrene by Mr. pradeep swarnkar

Phenanthrene is a polycyclic aromatic hydrocarbon composed of three fused benzene rings. It appears as a white powder with blue fluorescence. Phenanthrene shows aromatic properties and is the backbone molecule for morphine. It undergoes reactions like oxidation, reduction, bromination, and electrophilic addition or substitution. Derivatives of phenanthrene like papaverine are used as vasodilators to increase blood flow. Phenanthrene and its derivatives have several medicinal uses including manufacturing dyes, acting as antifungals, and being components of steroids, sex hormones, bile acids, and cardiac glycosides.

TABLET COATING

#Contents#

#DEFINITION

#OBJECTIVES OF TABLET COATING

#TABLET PROPERTIES

#EQUIPMENTS

#TYPES OF COATING

#FILM DEFECTS

#CONCLUSION

Size reduction

Size reduction is the process of reducing larger particles into smaller particles using external forces. The key mechanisms of size reduction are cutting, compression, impact, attrition, and a combination of impact and attrition. Different types of mills use these mechanisms, including hammer mills, ball mills, fluid energy mills, edge runner mills, and end runner mills. Factors like hardness, toughness, stickiness, softening temperature, and moisture content affect how easily a material can undergo size reduction. Laws of Rittinger, Kick, and Bond govern the energy requirements for size reduction.

DESIGN PROJECT 2013

This document provides a design for a plant to produce 400,000 metric tonnes of nitric acid per year using the Ostwald process. It selects a single pressure process as most advantageous after considering several factors such as efficient energy management. The process involves vaporizing ammonia at 1000 kPa and 35°C using process heat, then superheating it to 80°C with steam before mixing it with compressed air in a converter reactor over a platinum catalyst to produce nitrogen oxides, which are then absorbed in water to form the nitric acid product. The plant is estimated to cost ₦5.41 billion with a 26.25% return on investment and a 3 year, 7 month payback period, making the project technically

Histamin-Medicinal Chemistry MANIK

Histamines and antihistamines. Mode of action of histamines on cardiovascular system,

smooth muscle, gastric secretion, anaphylactic stock, histamine releasing drugs.

Allergic disorder, antihistamines: classification, pharmacological action. Action on CNS.

Therapeutic uses, absorption, distributions and excretion. Adverse reactions etc.

Triphenylmethane and derivatives

This document discusses triphenylmethane, which is a colorless solid hydrocarbon that serves as the basic skeleton for many synthetic dyes called triarylmethane dyes. It can be synthesized through various reactions including the Friedel-Crafts reaction of benzene and chloroform. As a triarylmethane, it is more acidic than other hydrocarbons due to delocalization of charge over three phenyl rings. Examples provided of triarylmethane dyes include bromocresol green and malachite green.

An Minh Tran - Case 2 - Cheg 407A (1)

This document presents a process design for producing ethanol from sugarcane at a plant in Louisiana. It includes mass and energy balances for the four main processes: milling, juice clarification, fermentation, and distillation. The total equipment cost is $21 million and the projected revenue is $145 million per year. A cash flow analysis over 20 years using a 7% discount rate yields a positive net present value of $60 million.

Flow properties of powders

This document discusses factors that affect the flow properties of powders. It describes three common tests to evaluate powder flowability: Carr's compressibility index, Hausner ratio, and angle of repose. Carr's index and Hausner ratio indicate flow based on tapped density measurements. Angle of repose measures the slope of a powder pile. The document also outlines factors like particle size, shape, surface forces, and additives that influence flow and methods to improve powder flow properties.

MOLECULAR DISTILLATION.pptx

Molecular distillation is a distillation process that occurs under high vacuum conditions. This allows molecules to travel through the vapor phase without intermolecular collisions before condensing individually on a nearby surface. There are two main types of molecular stills - falling film stills and centrifugal stills. Falling film stills use a heated surface and wipers to create a thin liquid film for evaporation, while centrifugal stills rotate a bucket at high speeds to create an evaporating liquid film on the inner wall. Both utilize a short path between evaporation and condensation surfaces to minimize molecular collisions in the vapor phase. Molecular distillation is useful for separating compounds with similar boiling points.

TOPIC - HAMMER MILL / SUBJECT- PHARMACEUTICS

The document discusses a hammer mill, which reduces particle size through repeated impacts using rotating hammers. It has various pharmaceutical uses including grinding raw materials and excipients. A hammer mill works by feeding materials into a chamber containing rapid rotating hammers that fracture particles through collisions. Properly sized particles pass through screens while larger ones require further grinding. Key advantages are rapid grinding and easy control of particle size. Disadvantages include potential heat damage and susceptibility to foreign objects in the feed.

Evaporation - Pharmaceutical Engineering 1st

Evaporation is the process of removing a solvent from a solution by heating the liquid in a vessel and collecting the vapor, leaving behind a concentrated product. Key factors that affect the evaporation rate include temperature, vapor pressure, surface area, and moisture content of the feed material. Common equipment used for evaporation include steam jacketed kettles, horizontal tube evaporators, and climbing film evaporators.

Drying by Ankita Yagnik

All about pharmaceutical drying.

Drying presentation for 2nd semester and 4th semester students as per GTU syllabus.

Evaporation by ankita yagnik

The document discusses evaporation, which is the process where molecules in a liquid spontaneously become a gas. Evaporation is used to concentrate solutions by removing vapor from a boiling liquid. Common examples include concentrating sugar and salt solutions. Evaporation occurs below the boiling point and only from the liquid surface, while distillation occurs at the boiling point and from the entire liquid mass. Multiple effect evaporators improve efficiency by using vapor from one vessel to heat the next at a lower pressure.

Natural dyes

Flavonoids are polyphenolic compounds found in plants. They have 15 carbon atoms arranged in two benzene rings connected by a 3 carbon chain. There are over 4,000 known flavonoids which serve important functions in plants like pigmentation and protecting against environmental toxins. The main classes of flavonoids include flavones, flavonols, flavanones, and anthocyanidins. Flavonoids act as antioxidants and have various health benefits like antiviral, anti-inflammatory, and antitumor properties. They can be identified through color reactions with acids or lead acetate and purified through chromatography techniques.

6. GLYCOSIDES.pptx

Glycosides are organic compounds formed by the bonding of a sugar molecule to a non-sugar aglycone. They are found in many plants and hydrolyze to release sugars and non-sugar aglycone portions with pharmacological activity. Some important classes of glycosides include anthraquinone glycosides like aloe, cardioactive glycosides like digitalis, saponin glycosides like licorice, and others. Glycosides have various uses as laxatives, heart medications, and flavorings depending on the biological activities of their aglycone components.

Industrial Pharmacy-I -Ophthalmic preparation part 3

Ophthalmic Preparations: Introduction, formulation considerations; formulation of eye drops, eye ointments and eye lotions; methods of preparation; labeling, containers;

evaluation of ophthalmic preparations

Unit 5-rheology

This document discusses rheology, which is the science describing the flow and deformation of matter under stress. It defines key terms like viscosity, shear stress, shear rate, and classifies fluids as Newtonian or non-Newtonian based on their relationship between shear stress and shear rate. Newtonian fluids have a constant viscosity regardless of shear rate, while non-Newtonian fluids have variable viscosity. Plastic, pseudoplastic, and dilatant behaviors are described for non-Newtonian fluids. Thixotropy, which is a time-dependent decrease and recovery of viscosity under shear, is also discussed. The document concludes by explaining the operation and calibration of common viscometers.

Drying

This document provides an overview of drying as an important unit operation in the pharmaceutical industry. It discusses the purposes of drying, different periods of drying, and classifications of dryers. It also describes several types of dryers commonly used in the pharmaceutical industry, including tray dryers, rotary dryers, fluidized bed dryers, freeze dryers, and dryers for slurries and suspensions. Special dryers like microwave and radio frequency dryers are also briefly mentioned.

Acidity of phenols

Acidity of Phenols/OC -II PCI Syllabus/Effect of substituents on acidity of phenols

Hi dear students, in this video I had explained about acidity of Phenols and Effect of substituents on acidity of phenols. I had tried to explain all the points by animations. So don't hasitate to study now, See this video and you will come to know the facts about acidity and basicity of organic compounds. After watching this video it will be very easy to answer the following questions,

What are phenols?

what about acidity of phenols?

factors affecting acidity of phenols?

Pka of phenols?

Please do subscribe Online ustaad and share this video to as many as possible.

Online Ustaad

https://www.youtube.com/channel/UCzCN5UTEjFAtCBtrcNOWbyA

Qualitative analysis of fats and oils

https://youtu.be/WXO6Ggdjwvo

you can also see

Is torrent downloading safe : https://youtu.be/vHjtNnXGztA

How To Make Youtube Thumbnail Free 2020 :https://youtu.be/Mvsl6P8z-Mk

Thumbnail Tips 2020 Hindi :https://youtu.be/H83VNRj_6gg

independence day status 2020 :https://youtu.be/0w7uq4bigFY

how to make you tube cover photo : https://youtu.be/k32Z-lXE7hc

How to cut a music file in 2 minutes :https://youtu.be/2wjfCOfOGGk

Keep watching your own channel online ustaad and give me your suggestions in comment box.

if you find this video helpful then like it, share it and subscribe online ustaad for more helpful & informational videos.

FOLLOW ME AT

dailyreviewz4@gmail.com

FACEBOOK : @onlineustaad4

INSTAGRAM : @online.ustaad

TWITTER : @onlineustaad4

#pcisyllabus #organicchemistry #pharmacy #pci #onlineustaad #tutorial #neetpreparation #bpharmacy #ugguide #bpharmacy3rdsem #pharmacytutorials

Drying rate

1) Drying curves plot drying rate versus remaining water content and can describe the drying process in steps with changing drying rates.

2) There is an initial constant rate period where unbound surface water is removed, followed by a falling rate period where the drying rate decreases as water moves internally through the material.

3) Drying rates determined experimentally can be used to calculate drying times to design drying equipment and operations. Simplified calculations can provide useful estimates by assuming constant temperature and humidity.

Packed bed flooding

The document discusses packed column design parameters including packing factor (Fp), kinematic viscosity (ν), C-factor (CS), capacity factor (CP), and flow parameter (FLG). It summarizes pressure drop correlations from the Generalized Pressure Drop Correlation (GPDC) and modifications by Kister and Gill. It also discusses methods for determining flood point from the flood pressure drop equation and notes alternative methods for predicting flood and pressure drop.

PRACTICAL 1: GENERAL LABORATORY PROCEDURES

This document contains the details of a biochemistry practical completed by Mohamed Reda. It includes exercises on basic laboratory calculations involving units conversions, molar concentrations, dilutions and serial dilutions. The practical also covers topics like positive displacement pipettes, air displacement pipettes and techniques to improve pipetting accuracy.

Assignment 1

This document contains 4 problems related to drying processes and membrane separation systems. Problem 1 involves calculating the amount of water removed when drying food from 400% to 25% moisture content. Problem 2 involves calculating flow rates for a two-stage membrane separation process concentrating liquid food from 12% to 45% total solids. Problem 3 involves calculating quantities of waste stream and peeled potatoes using steam for potato peeling. Problem 4 involves calculating the mass flow rate and dry basis moisture content of dried potato flakes using concurrent flow drying.

More Related Content

What's hot

TABLET COATING

#Contents#

#DEFINITION

#OBJECTIVES OF TABLET COATING

#TABLET PROPERTIES

#EQUIPMENTS

#TYPES OF COATING

#FILM DEFECTS

#CONCLUSION

Size reduction

Size reduction is the process of reducing larger particles into smaller particles using external forces. The key mechanisms of size reduction are cutting, compression, impact, attrition, and a combination of impact and attrition. Different types of mills use these mechanisms, including hammer mills, ball mills, fluid energy mills, edge runner mills, and end runner mills. Factors like hardness, toughness, stickiness, softening temperature, and moisture content affect how easily a material can undergo size reduction. Laws of Rittinger, Kick, and Bond govern the energy requirements for size reduction.

DESIGN PROJECT 2013

This document provides a design for a plant to produce 400,000 metric tonnes of nitric acid per year using the Ostwald process. It selects a single pressure process as most advantageous after considering several factors such as efficient energy management. The process involves vaporizing ammonia at 1000 kPa and 35°C using process heat, then superheating it to 80°C with steam before mixing it with compressed air in a converter reactor over a platinum catalyst to produce nitrogen oxides, which are then absorbed in water to form the nitric acid product. The plant is estimated to cost ₦5.41 billion with a 26.25% return on investment and a 3 year, 7 month payback period, making the project technically

Histamin-Medicinal Chemistry MANIK

Histamines and antihistamines. Mode of action of histamines on cardiovascular system,

smooth muscle, gastric secretion, anaphylactic stock, histamine releasing drugs.

Allergic disorder, antihistamines: classification, pharmacological action. Action on CNS.

Therapeutic uses, absorption, distributions and excretion. Adverse reactions etc.

Triphenylmethane and derivatives

This document discusses triphenylmethane, which is a colorless solid hydrocarbon that serves as the basic skeleton for many synthetic dyes called triarylmethane dyes. It can be synthesized through various reactions including the Friedel-Crafts reaction of benzene and chloroform. As a triarylmethane, it is more acidic than other hydrocarbons due to delocalization of charge over three phenyl rings. Examples provided of triarylmethane dyes include bromocresol green and malachite green.

An Minh Tran - Case 2 - Cheg 407A (1)

This document presents a process design for producing ethanol from sugarcane at a plant in Louisiana. It includes mass and energy balances for the four main processes: milling, juice clarification, fermentation, and distillation. The total equipment cost is $21 million and the projected revenue is $145 million per year. A cash flow analysis over 20 years using a 7% discount rate yields a positive net present value of $60 million.

Flow properties of powders

This document discusses factors that affect the flow properties of powders. It describes three common tests to evaluate powder flowability: Carr's compressibility index, Hausner ratio, and angle of repose. Carr's index and Hausner ratio indicate flow based on tapped density measurements. Angle of repose measures the slope of a powder pile. The document also outlines factors like particle size, shape, surface forces, and additives that influence flow and methods to improve powder flow properties.

MOLECULAR DISTILLATION.pptx

Molecular distillation is a distillation process that occurs under high vacuum conditions. This allows molecules to travel through the vapor phase without intermolecular collisions before condensing individually on a nearby surface. There are two main types of molecular stills - falling film stills and centrifugal stills. Falling film stills use a heated surface and wipers to create a thin liquid film for evaporation, while centrifugal stills rotate a bucket at high speeds to create an evaporating liquid film on the inner wall. Both utilize a short path between evaporation and condensation surfaces to minimize molecular collisions in the vapor phase. Molecular distillation is useful for separating compounds with similar boiling points.

TOPIC - HAMMER MILL / SUBJECT- PHARMACEUTICS

The document discusses a hammer mill, which reduces particle size through repeated impacts using rotating hammers. It has various pharmaceutical uses including grinding raw materials and excipients. A hammer mill works by feeding materials into a chamber containing rapid rotating hammers that fracture particles through collisions. Properly sized particles pass through screens while larger ones require further grinding. Key advantages are rapid grinding and easy control of particle size. Disadvantages include potential heat damage and susceptibility to foreign objects in the feed.

Evaporation - Pharmaceutical Engineering 1st

Evaporation is the process of removing a solvent from a solution by heating the liquid in a vessel and collecting the vapor, leaving behind a concentrated product. Key factors that affect the evaporation rate include temperature, vapor pressure, surface area, and moisture content of the feed material. Common equipment used for evaporation include steam jacketed kettles, horizontal tube evaporators, and climbing film evaporators.

Drying by Ankita Yagnik

All about pharmaceutical drying.

Drying presentation for 2nd semester and 4th semester students as per GTU syllabus.

Evaporation by ankita yagnik

The document discusses evaporation, which is the process where molecules in a liquid spontaneously become a gas. Evaporation is used to concentrate solutions by removing vapor from a boiling liquid. Common examples include concentrating sugar and salt solutions. Evaporation occurs below the boiling point and only from the liquid surface, while distillation occurs at the boiling point and from the entire liquid mass. Multiple effect evaporators improve efficiency by using vapor from one vessel to heat the next at a lower pressure.

Natural dyes

Flavonoids are polyphenolic compounds found in plants. They have 15 carbon atoms arranged in two benzene rings connected by a 3 carbon chain. There are over 4,000 known flavonoids which serve important functions in plants like pigmentation and protecting against environmental toxins. The main classes of flavonoids include flavones, flavonols, flavanones, and anthocyanidins. Flavonoids act as antioxidants and have various health benefits like antiviral, anti-inflammatory, and antitumor properties. They can be identified through color reactions with acids or lead acetate and purified through chromatography techniques.

6. GLYCOSIDES.pptx

Glycosides are organic compounds formed by the bonding of a sugar molecule to a non-sugar aglycone. They are found in many plants and hydrolyze to release sugars and non-sugar aglycone portions with pharmacological activity. Some important classes of glycosides include anthraquinone glycosides like aloe, cardioactive glycosides like digitalis, saponin glycosides like licorice, and others. Glycosides have various uses as laxatives, heart medications, and flavorings depending on the biological activities of their aglycone components.

Industrial Pharmacy-I -Ophthalmic preparation part 3

Ophthalmic Preparations: Introduction, formulation considerations; formulation of eye drops, eye ointments and eye lotions; methods of preparation; labeling, containers;

evaluation of ophthalmic preparations

Unit 5-rheology

This document discusses rheology, which is the science describing the flow and deformation of matter under stress. It defines key terms like viscosity, shear stress, shear rate, and classifies fluids as Newtonian or non-Newtonian based on their relationship between shear stress and shear rate. Newtonian fluids have a constant viscosity regardless of shear rate, while non-Newtonian fluids have variable viscosity. Plastic, pseudoplastic, and dilatant behaviors are described for non-Newtonian fluids. Thixotropy, which is a time-dependent decrease and recovery of viscosity under shear, is also discussed. The document concludes by explaining the operation and calibration of common viscometers.

Drying

This document provides an overview of drying as an important unit operation in the pharmaceutical industry. It discusses the purposes of drying, different periods of drying, and classifications of dryers. It also describes several types of dryers commonly used in the pharmaceutical industry, including tray dryers, rotary dryers, fluidized bed dryers, freeze dryers, and dryers for slurries and suspensions. Special dryers like microwave and radio frequency dryers are also briefly mentioned.

Acidity of phenols

Acidity of Phenols/OC -II PCI Syllabus/Effect of substituents on acidity of phenols

Hi dear students, in this video I had explained about acidity of Phenols and Effect of substituents on acidity of phenols. I had tried to explain all the points by animations. So don't hasitate to study now, See this video and you will come to know the facts about acidity and basicity of organic compounds. After watching this video it will be very easy to answer the following questions,

What are phenols?

what about acidity of phenols?

factors affecting acidity of phenols?

Pka of phenols?

Please do subscribe Online ustaad and share this video to as many as possible.

Online Ustaad

https://www.youtube.com/channel/UCzCN5UTEjFAtCBtrcNOWbyA

Qualitative analysis of fats and oils

https://youtu.be/WXO6Ggdjwvo

you can also see

Is torrent downloading safe : https://youtu.be/vHjtNnXGztA

How To Make Youtube Thumbnail Free 2020 :https://youtu.be/Mvsl6P8z-Mk

Thumbnail Tips 2020 Hindi :https://youtu.be/H83VNRj_6gg

independence day status 2020 :https://youtu.be/0w7uq4bigFY

how to make you tube cover photo : https://youtu.be/k32Z-lXE7hc

How to cut a music file in 2 minutes :https://youtu.be/2wjfCOfOGGk

Keep watching your own channel online ustaad and give me your suggestions in comment box.

if you find this video helpful then like it, share it and subscribe online ustaad for more helpful & informational videos.

FOLLOW ME AT

dailyreviewz4@gmail.com

FACEBOOK : @onlineustaad4

INSTAGRAM : @online.ustaad

TWITTER : @onlineustaad4

#pcisyllabus #organicchemistry #pharmacy #pci #onlineustaad #tutorial #neetpreparation #bpharmacy #ugguide #bpharmacy3rdsem #pharmacytutorials

Drying rate

1) Drying curves plot drying rate versus remaining water content and can describe the drying process in steps with changing drying rates.

2) There is an initial constant rate period where unbound surface water is removed, followed by a falling rate period where the drying rate decreases as water moves internally through the material.

3) Drying rates determined experimentally can be used to calculate drying times to design drying equipment and operations. Simplified calculations can provide useful estimates by assuming constant temperature and humidity.

Packed bed flooding

The document discusses packed column design parameters including packing factor (Fp), kinematic viscosity (ν), C-factor (CS), capacity factor (CP), and flow parameter (FLG). It summarizes pressure drop correlations from the Generalized Pressure Drop Correlation (GPDC) and modifications by Kister and Gill. It also discusses methods for determining flood point from the flood pressure drop equation and notes alternative methods for predicting flood and pressure drop.

What's hot (20)

Industrial Pharmacy-I -Ophthalmic preparation part 3

Industrial Pharmacy-I -Ophthalmic preparation part 3

Similar to FTECH 3310 Food Engg Lecture 1.pptx

PRACTICAL 1: GENERAL LABORATORY PROCEDURES

This document contains the details of a biochemistry practical completed by Mohamed Reda. It includes exercises on basic laboratory calculations involving units conversions, molar concentrations, dilutions and serial dilutions. The practical also covers topics like positive displacement pipettes, air displacement pipettes and techniques to improve pipetting accuracy.

Assignment 1

This document contains 4 problems related to drying processes and membrane separation systems. Problem 1 involves calculating the amount of water removed when drying food from 400% to 25% moisture content. Problem 2 involves calculating flow rates for a two-stage membrane separation process concentrating liquid food from 12% to 45% total solids. Problem 3 involves calculating quantities of waste stream and peeled potatoes using steam for potato peeling. Problem 4 involves calculating the mass flow rate and dry basis moisture content of dried potato flakes using concurrent flow drying.

Lecture 02: STKM3212

The document discusses mass balance concepts in food processing systems operating at steady state. It defines different types of processes (batch, continuous, semi-batch) and steady vs unsteady state. Examples of mass balance problems are provided for dilution, evaporation/concentration, and mixing processes. Component balances are used to solve problems involving multiple streams and components.

Chapter 1

This document provides an overview of units of measurement commonly used in environmental management and materials and energy balances. It defines SI and other units for length, mass, temperature, area, volume, energy, power, velocity, flow rate, density, and concentration. It presents prefixes used with units to describe large and small quantities. Examples show calculations of concentration in terms of mass per volume, parts per million, percentage, and air pollutant concentrations. The document stresses the importance of materials and energy balances in understanding processes and their environmental impacts, and provides examples of calculating particulate concentration, dust collection in a bag house system, and pollutant emissions from a coal-fired power plant.

Stoichiometry

The document discusses different types of stoichiometry calculations encountered in AS Organic Chemistry, including:

1) Percentage yield calculations from chemical reactions.

2) Determining empirical formulas from elemental analysis data involving masses, percentages, or combustion analysis.

3) Calculating molecular formulas using empirical formulas and experimentally determined molar masses.

Chemical Reaction Stoichiometry

Chemical Reaction Stoichiometry. Practical matters in chemical reaction stoichiometry.

Haber process to produce ammonia. production of ammonia from Calcium cyanamide. Manganese dioxide to produce chlorine.

Material balance problem without chemical reaction

Evaporator - Crystallizer Unit

Prepared by :

19013123-019 M. Faheem Ullah

University of Gujrat

Presentation data logger

The document summarizes an experiment on the effect of carbon dioxide concentration on the rate of photosynthesis. Students connected an oxygen sensor to interfacing software and measured oxygen production in a Hydrilla plant exposed to varying concentrations of sodium hydrogen carbonate solution as a CO2 source. Results showed that as carbon dioxide concentration increased, the rate of photosynthesis also increased, indicating a direct relationship between carbon dioxide levels and photosynthesis.

Improve the extraction efficiency of a tandem sugarcane mil

This project was implemented in Sugar Mill San José de Abajo S.A de C.V., in which there were problems due to sugar losses (Pol), this process is located in the department of mills (extraction). Through the investigation, important data were obtained on the losses of Pol in bagasse, which is very significant for the company. Through the literature we were able to document the adjustments, values, parameters, among other factors that influence good extraction, in order to reduce losses and generate improvements to the process for the benefit of all. The results of the 2016-2017 harvest were analyzed in order to seek improvements, which with hard work and effort were proposed and considered by the technical staff, and which could be used for the sugar industry.

CBE 250 Process Design Report

The process involves fermenting a glucose-water solution with E. coli to produce succinic acid. The fermentation broth is then separated through filtration, liquid-liquid extraction with 1-octanol, and crystallization to obtain purified succinic acid crystals and recycled glucose-water solution. The succinic acid can be used to produce various derivatives for applications in industries like food, electronics, and automotive. Preliminary calculations show the process could yield a net profit of $166400 per year.

Sludge treatment and disposal 1

The document discusses sludge treatment and disposal methods. It describes the processes of sludge digestion where sludge undergoes acid fermentation, acid regression and alkaline fermentation stages. Key factors like temperature, pH, seeding and mixing that affect digestion are also covered. Sludge digestion tanks are cylindrical with a conical bottom. Design considerations for sizing digestion tanks are provided. The document also discusses dewatering digested sludge using drying beds or mechanical methods like centrifuges.

Chapter 2 solutions

1. The document contains solved problems related to solutions from Class 12 Chemistry Chapter 2.

2. It discusses concepts like mass percentage, mole fraction, molarity, molality, vapour pressure, boiling point elevation, freezing point depression and osmotic pressure.

3. Various types of problems are solved which involve calculating quantities related to solutions using concepts like Raoult's law and Henry's law.

IB Exam Question on Titration, Uncertainty calculation, Ideal Gas and Open En...

The document describes several titration experiments:

1) Titration of ethanoic acid in vinegar with sodium hydroxide to determine its molarity. The vinegar was diluted before titration.

2) Titration of hydrated sodium carbonate with hydrochloric acid to determine its molarity and empirical formula.

3) Iodometric titration of vitamin C with potassium iodate to determine the amount of vitamin C.

4) Titration of iron in an iron tablet with potassium manganate to determine the percentage of iron.

5) Titration of chlorine in bleach with sodium thiosulfate after reaction with potassium iodide to determine its molarity.

Solution and colligative numerical 2016

The document provides examples of calculating various properties of solutions such as percentage by mass, mole fraction, molarity, molality, vapor pressure depression, boiling point elevation, and Henry's law constant. It includes 18 examples involving dissolving various solutes like glucose, methyl alcohol, benzene, HCl, NaOH, urea, mannitol, and methane in solvents like water, xylene, chloroform to calculate related chemical properties.

Food engineering kyambogo university faculty of science

course work chemical engineering year 4 semester 1 food engineering. PASTEURIZATION AND MATERIAL BALANCE IN CONTINUOUS PROCESSING OF FOOD.

Cel795 hw8 solution and additional problems

This document contains solutions and additional questions related to water and wastewater treatment processes. It includes solutions to questions about batch reactor kinetics, anaerobic digester design, activated sludge process design, oxygen requirements, and sludge production calculations. Additional questions cover topics like sludge volume reduction from dewatering, volatile solids destruction during digestion, and methane production in anaerobic reactors.

Production of mea triazine m1

The document is a project report for manufacturing MEA TRIAZINE from paraformaldehyde and monoethanol amine. MEA TRIAZINE is used as H2S scavanger in crude oilfields.

Excercise pc 20172018

This document provides an example exercise involving the scrubbing of SO2 gas using a packed column with water. It asks the reader to:

1) Calculate the L/Lmin ratio based on the inlet/outlet SO2 concentrations and gas/liquid flow rates.

2) Determine the number of theoretical stages (NOG) and compare to the HETP calculation.

3) Calculate the height of transfer unit (HOG) and HETP from the operating data.

4) Find the volumetric gas-liquid mass transfer coefficient (KGa) using the given partial pressure driving force relationship.

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with .docx

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with Vinegar

Objectives: To visually observe what a limiting reactant is.

To measure the change in mass during a chemical reaction due to loss of a gas.

To calculate CO2 loss and compare actual loss to expected CO2 loss predicted by the balanced chemical equation.

Materials needed: Note: Plan ahead as you’ll need to let Part 1 sit for at least 24 hours.

plastic beaker graduated cylinder

electronic balance 2 eggs

1 plastic cup baking soda (5 g)

dropper vinegar (500mL)

2 identical cups or glasses (at least 500 mL)

Safety considerations: Safety goggles are highly recommended for this lab as baking soda and vinegar chemicals can be irritating to the eyes. If your skin becomes irritated from contact with these chemicals, rinse with cool water for 15 minutes.

Introduction:

The reaction between baking soda and vinegar is a fun activity for young people. Most children (and adults!) enjoy watching the foamy eruption that occurs upon mixing these two household substances. The reaction has often been used for erupting volcanoes in elementary science classes. The addition of food coloring makes it even more fun. The reaction involves an acid-base reaction that produces a gas (CO2). Acid-base reactions typically involve the transfer of a hydrogen ion (H+) from the acid (HA) to the base (B−):

HA + B− --> A− + BH (eq #1)

acid base

The base often (although not always) carries a negative charge. The acid usually (although not always) becomes negatively charged through the course of the reaction because it lost an H+. An example of a typical acid base reaction is below:

HCl(aq) + NaOH(aq) --> NaCl(aq) + H2O(l) (eq #2)

The reaction is actually taking place between the hydrogen ion (H+) and the hydroxide ion (OH−). The chloride and sodium are spectator ions. To write the reaction in the same form as eq #1:

HCl(aq) + OH- --> Cl- + H2O (l) (eq #3)

Sodium bicarbonate (NaHCO3) will dissociate in water to form sodium ion (Na+) and bicarbonate ion (HCO3−).

NaHCO3 --> Na+ + HCO3− (eq #4)

Vinegar is usually a 5% solution of acetic acid in water. The bicarbonate anion (HCO3−) can act as a base, accepting a hydrogen ion from the acetic acid (HC2H3O2) in the vinegar. The Na+ is just a spectator ion and does nothing.

HCO3− + HC2H3O2 --> H2CO3 + C2H3O2− (eq#5)

Bicarbonate acetic acid carbonic acid acetate ion

The carbonic acid that is formed (H2CO3) decomposes to form water and carbon dioxide:

H2CO3 --> H2O(l) + CO2(g) (eq#6)

carbonic acid water carbon dioxide

The latter reaction (production of carbon dioxide) accounts for the bubbles and the foaming that is observed upon mixing vinegar and baki.

Ejercicio 6 recirculacion

A solid material containing 15% moisture by weight is dried in a rotary dryer to reduce the moisture content to 7% by weight. Hot air mixed with recirculated air from the dryer is used for drying. Calculations are shown to determine the mass flow rates of fresh air, recirculated air, and product based on a solid feed rate of 100 kg/hr to the dryer. Mass balances are performed around the dryer, mixer, and divider to calculate the flow rates, resulting in 96.70 kg/hr of fresh air, 29.84 kg/hr of recirculated air, and 91.40 kg/hr of product.

Similar to FTECH 3310 Food Engg Lecture 1.pptx (20)

Material balance problem without chemical reaction

Material balance problem without chemical reaction

Improve the extraction efficiency of a tandem sugarcane mil

Improve the extraction efficiency of a tandem sugarcane mil

IB Exam Question on Titration, Uncertainty calculation, Ideal Gas and Open En...

IB Exam Question on Titration, Uncertainty calculation, Ideal Gas and Open En...

Food engineering kyambogo university faculty of science

Food engineering kyambogo university faculty of science

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with .docx

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with .docx

More from JoannDavid4

Lec 3Agencies in implementing Food Laws.pptx

The roles of government, industry, and consumers in ensuring food safety are outlined. Key government agencies in the Philippines that regulate different parts of the food chain are the Department of Agriculture, Department of Health including the Food and Drug Administration, and local government units. These agencies set food safety standards and regulations. Food business operators are primarily responsible for producing safe food while consumers have responsibilities such as proper food handling and checking labels. Collaboration between these groups helps strengthen the food regulatory system and protect public health.

3d - Food Preparation Basics _ Seasonings and Flavorings.pptx

This document provides an overview of seasonings and flavorings used in food preparation. It discusses the main categories of seasonings which include salt, pepper, herbs, spices, flavor enhancers, oil extracts, marinades, breading and batters, and condiments. For each category, some common examples are listed and brief descriptions of each are given, such as the different types of salt and their uses, and how herbs and spices are obtained from different parts of plants. Information is also provided on storage of dried spices and herbs to maintain optimal potency.

Lecture 3 GMP and PRP.pptx

This document provides an overview of Good Manufacturing Practices (GMP) and Pre-Requisite Programs (PRP) for maintaining food safety and quality. It discusses 10 key aspects of GMP including cleaning, pest control, personnel hygiene, and facility maintenance. It then describes 14 PRPs which expand upon GMPs and include additional programs for allergens, traceability, and cleaning validation. Finally, it provides detailed descriptions of PRP1 (cleaning and disinfection), PRP2 (pest control), and PRP3 (water quality), outlining procedures, responsibilities, and documentation required for effective implementation.

FT 2110 Lecture Chap 4 _ Meat.pptx

This document provides an overview of meat types and meat composition. It discusses the different types of meat including beef, veal, lamb, mutton, and pork. It describes the main components of meat - muscle tissue, connective tissue, adipose tissue, bone, marrow, pigments, extractives. It explains how these components, along with the animal's age, diet and cut of meat can impact tenderness. It also outlines natural and artificial tenderizing methods used in meat production and processing.

5 _ Poultry.pptx

This document provides information about poultry, including:

- Poultry refers to domesticated birds raised for meat, mainly chickens but also turkeys, ducks, and others.

- Poultry is classified by age and gender and has a similar composition to other meats.

- It describes various preparation methods for poultry as well as tips for ensuring food safety during preparation.

- Guidelines are provided for properly cooking poultry to a safe internal temperature and determining doneness.

FT 2110 Lecture Chap 4 _ Meat.pptx

This document discusses meat composition and tenderness. It defines meat as animal muscle and organ tissue. Types of meat covered include beef from cattle of different ages/genders, lamb/mutton from sheep, and pork from pigs. Meat is composed of muscle, connective tissue like collagen, fat, and sometimes bone. More collagen makes meat tougher, while fat adds flavor and juiciness. Tenderness depends on factors like the animal's diet, age at slaughter, and cut of meat. Dry or wet aging can further increase tenderness.

More from JoannDavid4 (6)

3d - Food Preparation Basics _ Seasonings and Flavorings.pptx

3d - Food Preparation Basics _ Seasonings and Flavorings.pptx

FTECH 3310 Food Engg Lecture 1.pptx

- 1. Sample Problem #1…..continuation Step 2: State your assumptions: dry sugar is composed of 100% sugar. Step 3: Write the total and component mass balances in the envelope around the process: a) Total mass balance 100 + S2 = S3 B) Component mass balance: Soluble solids mass balance (0.20 X 100) + (S2 X 1) = (0:50 X S3) 20 + S = 0.5S Solving eqns (3.1) and (3.2) simultaneously, find S2=60 kg and S3=160 kg. Therefore 60 kg of dry sugar per 100 kg of feed must be added to increase its concentration from 20% to 50%.

- 2. FTECH 3310: Food Engineering ASSOC. PROF. JOANN DAVID DAR DEPT. OF FOOD SCIENCE AND TECHNOLOGY, CHSI, CLSU PGS FOOD SAFETY, QA SYSTEMS AND RISK ANALYSIS, UNIVERSITEIT GENT -BELGIUM M.SC. FOOD SCIENCE AND TECHNOLOGY, ENSIA -SIARC - FRANCE BS FOOD TECHNOLOGY, CLSU -PHILIPPINES

- 3. Unit 1: Review of Mathematical Principles in Food Engineering

- 4. Unit 2: Units and Dimensions

- 5. Sample Problem #1: Mixing Example 3.1 How much dry sugar must be added in 100 kg of aqueous sugar solution in order to increase its concentration from 20% to 50%? S1 100 KG 20% S2 50% S3 100% MIXING

- 6. Sample Problem #1...continuation.. Mixing Step 2: State your assumptions: dry sugar is composed of 100% sugar. Step 3: Write the total and component mass balances in the envelope around the process: a) Total mass balance 100 + S2 = S3 B) Component mass balance: Soluble solids mass balance (0.20 X 100) + (S2 X 1) = (0:50 X S3) 20 + S = 0.5S Solving eqns (3.1) and (3.2) simultaneously, find S2=60 kg and S3=160 kg. Therefore 60 kg of dry sugar per 100 kg of feed must be added to increase its concentration from 20% to 50%.

- 7. Sample Problem #2: Evaporation and Mixing Example 3.2 Fresh orange juice with 12% soluble solids content is concentrated to 60% in a multiple effect evaporator. To improve the quality of the final product the concentrated juice is mixed with an amount of fresh juice (cut back) so that the concentration of the mixture is 42%. Calculate how much water per hour must be evaporated in the evaporator, how much fresh juice per hour must be added back and how much final product will be produced if the inlet feed flow rate is 10000 kg/h fresh juice. Assume steady state. 10,000 kg/h 12% W 42% S3 100% Evaporation (I) Mixing X 60% 12% F Y I II

- 8. Sample Problem #2…..continuation Step 2: Write the total and component mass balances in envelopes I and II: a) Total mass balance - in envelope I 10,000 = W+X b) Component mass balance: Soluble solids mass balance in envelope I 0.12 X 10,000 = 0.60 X c) Total mass balance in envelope II X + F = Y d) Component mass balance: Soluble solids mass balance in envelope II (0:60 * X) + (0:12*F) =(0.42 * Y)

- 9. Sample Problem #2…..continuation From equation (3.4) find X=2000 kg/h. Substituting X in eqn (3.3) and find W=8000 kg/h. Solve eqns (iii) and (iv) simultaneously and Substitute X in eqn (3.3) and find=1200 kg/h and Y=3200 kg/h. Therefore 8000 kg/h of water will be evaporated, 1200 kg/h of fresh juice will be added back and 3200 kg/h of concentrated orange juice with 42% soluble solids will be produced.

- 10. Sample Problem #3: Concentration Exercise 3.3 A fruit juice with 1,000 kg/h with 10% solids is freeze-concentrated to 40% solids. The dilute juice is fed to a freezer where the ice crystals are formed and then the slush is separated in a centrifugal separator into ice crystals and concentrated juice. An amount of 500 kg/h of liquid is recycled from the separator to the freezer. Calculate the amount of ice that is removed in the separator and the amount of concentrated juice produced. Assume steady state. Solution: Step 1 - Draw the process diagram: 1,000 kg/h 10% 42% Freezing (I) Separation J II Ice I

- 11. Sample Problem #3: Concentration…..continuation Step 2: Write the total and component mass balances in the envelope around the process: a) Total mass balance 1000 = I + J (Equation 3:7) b) Component mass balance : Soluble solids mass balance 0:10 X 1000 = 0.40 X J (Equation 3.8) From eqn (3.8), find J=250 kg/h and then from eqn (3.7) find I=750 kg/h. Comment: Notice that the recycle stream does not affect the result. Only the streams that cut the envelope take part in the mass balance.