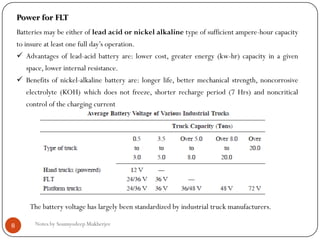

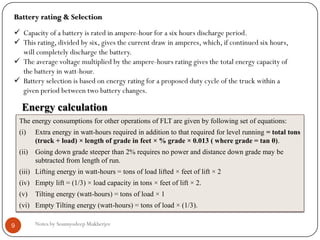

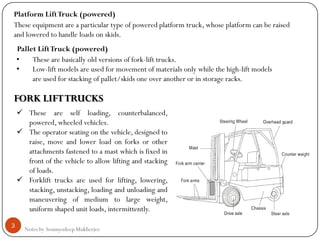

The document discusses various types of powered industrial trucks, including platform trucks, pallet lift trucks, and forklift trucks, outlining their functionalities and specifications. It details the classification of powertrucks based on power source, mode of action, and other factors, as well as capacity ratings and attachment options for forklifts. Additionally, it covers battery types, selection criteria, and energy consumption calculations for efficient operation.

![Notes by Soumyodeep Mukherjee5

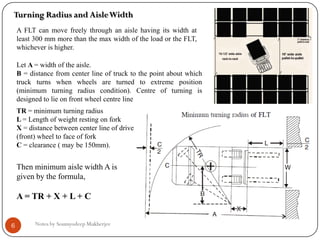

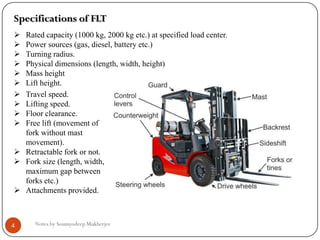

Capacity rating of FLT

FLT’s are specified for a rated capacity at a specified load centre.

Load centre is the distance from the heel (vertical face) of the forks to the assumed c.g. of the load.

The moment of the load about the front wheel does not exceed that of the counter-loaded body of

truck.

Rated capacity of the FLT is X kg and load centre is Y mm. Let the distance

between front wheels to heel of the fork (distance A to B) is Z mm.

Then true capacity of the FLT is

= X × (load centre + distance A to B)

True capacity of the FLT = X × (Y + Z) kg.mm.

If a load is to be carried whose c.g. ‘‘C’’ is

at a distance of P mm from the heel of the

forks (distance B to C = P), then the

maximum safe weight ‘‘W’’ that can be

carried is given by the equation:

W = [X × (Y + Z)] / [Z+P] kg](https://image.slidesharecdn.com/module3flt-200424065000/85/Fork-Lift-Truck-5-320.jpg)