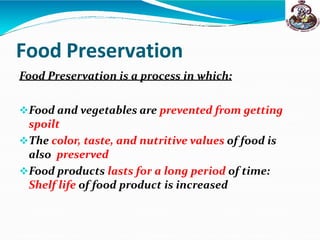

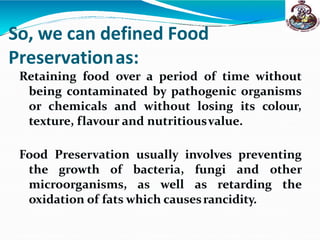

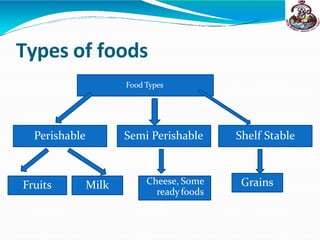

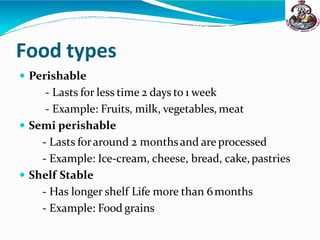

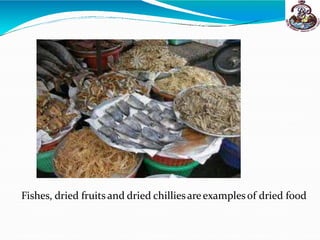

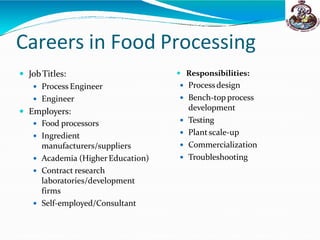

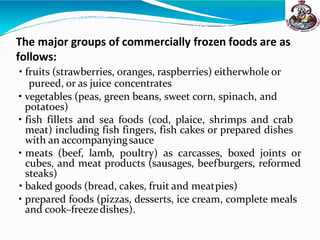

This document provides an overview of food processing and preservation. It discusses how preserving foods allows people to enjoy foods like mangoes throughout the year. Various food preservation methods are described, including canning, drying, salting, freezing, and smoking. These methods help prevent spoilage by inhibiting microbial growth and retarding oxidation. The principles of food preservation and various techniques, like physical and chemical methods, are also outlined. Careers in food processing are mentioned. Important unit operations in food processing, like mixing, cooking, and packaging are listed. Dehydration as a preservation method is further described.