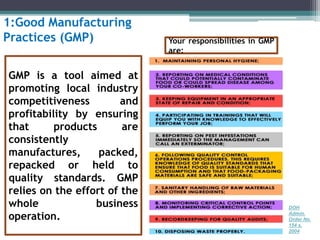

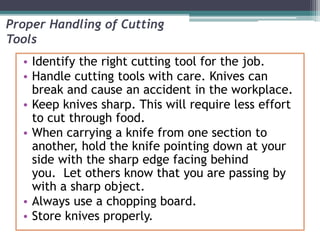

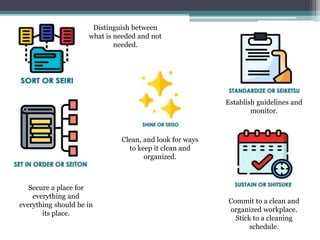

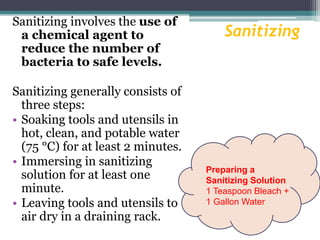

The document outlines essential food manufacturing practices, focusing on good manufacturing practices (GMP), occupational safety, and equipment cleaning and sanitizing. It emphasizes the importance of maintaining hygiene, implementing proper waste disposal, and utilizing personal protective equipment to ensure safety in food processing environments. Additionally, it highlights the significance of a clean workplace through the 5S methodology and proper management of chemical waste.