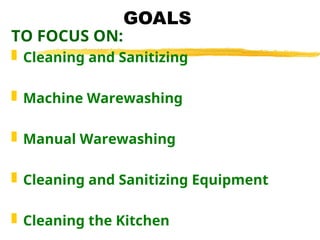

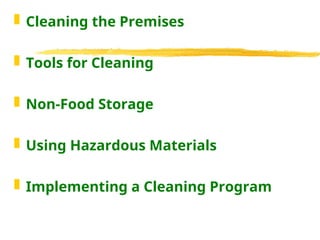

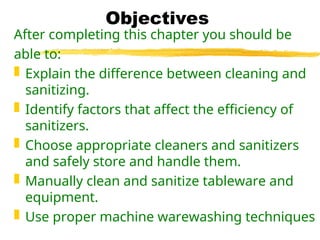

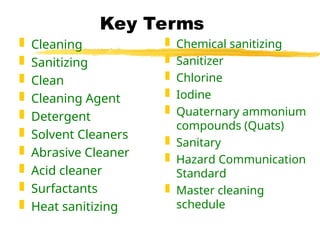

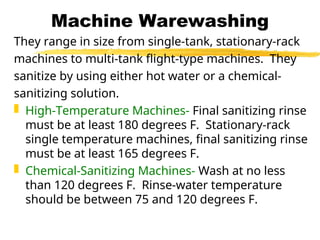

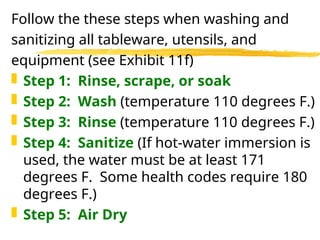

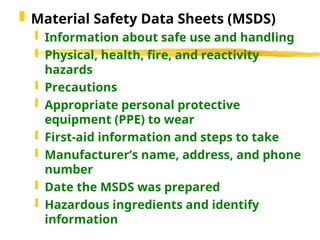

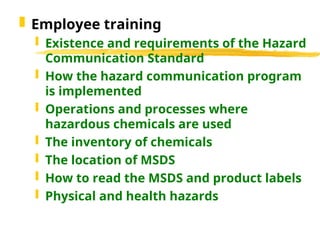

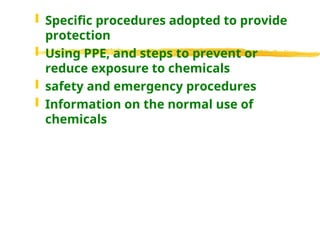

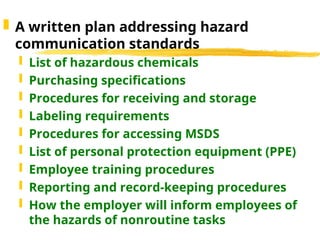

The document outlines the essential practices for cleaning and sanitizing in food service environments, emphasizing the distinction between cleaning (removing soil from surfaces) and sanitizing (reducing microorganisms to safe levels). It details various cleaning agents, methods of sanitization, and the necessity of a structured cleaning program, including the use of machines and manual warewashing procedures. Additionally, it highlights the importance of complying with hazardous materials regulations and implementing a master cleaning schedule to maintain a safe and sanitary operation.