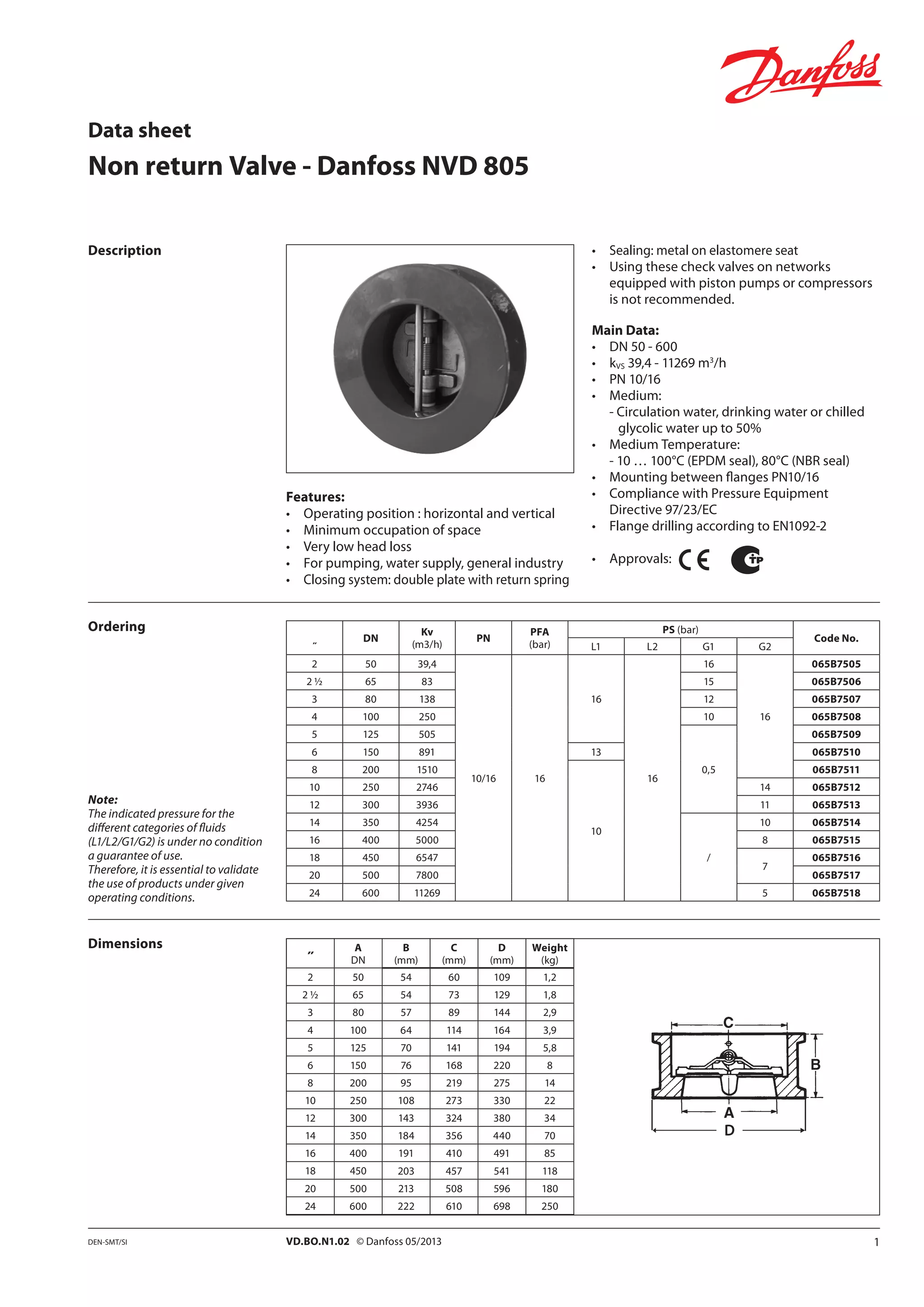

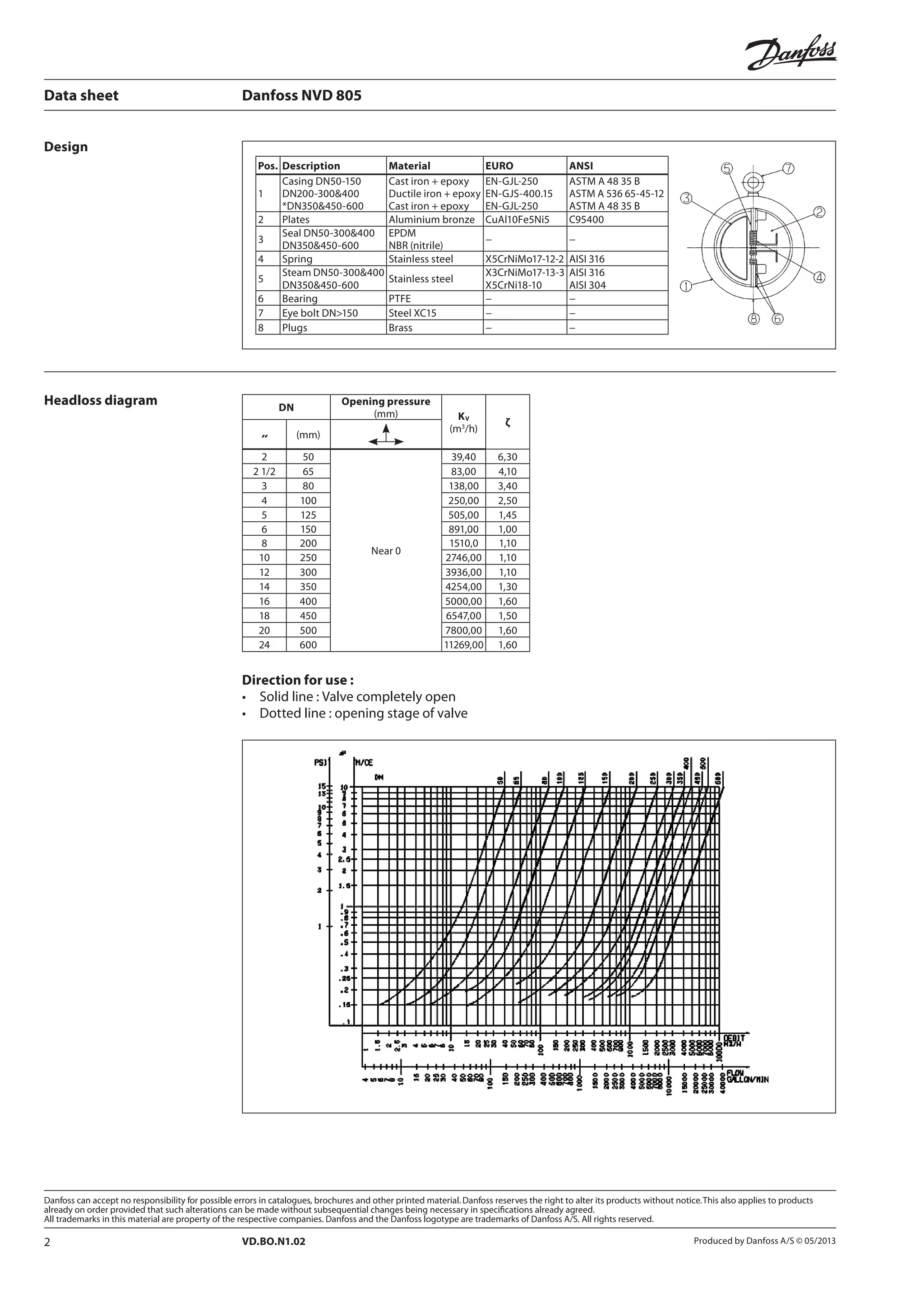

This document provides specifications for the Danfoss NVD 805 non-return valve. It is available in sizes from DN50 to DN600, with Kv values ranging from 39.4 to 11269 m3/h. It features a double plate closing system with a return spring and metal-elastomer sealing. It is designed for horizontal or vertical installation in pumping, water supply, and general industrial applications handling water or glycol mixtures up to 50% and temperatures from 10 to 100°C.