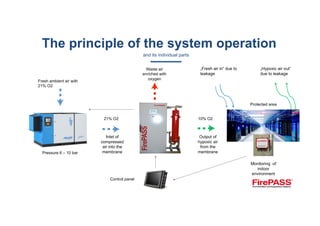

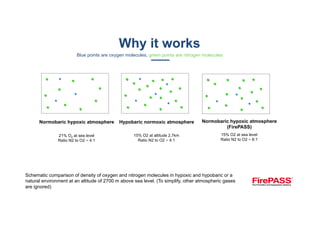

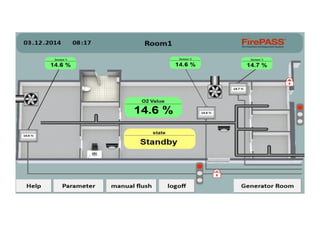

1) The FirePASS system creates a hypoxic environment of around 10-15% oxygen to prevent fires from starting or spreading. This is done through an oxygen filtration membrane that produces hypoxic air on site.

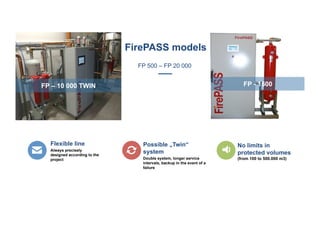

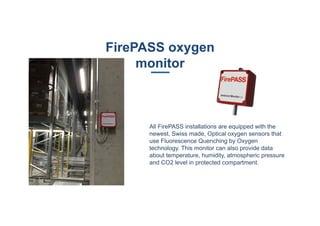

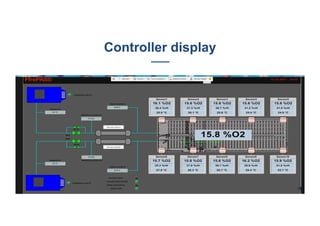

2) The hypoxic air is continuously replenished and monitored to maintain oxygen levels that are safe for humans but prevent combustion. Various models are available to suit different space volumes.

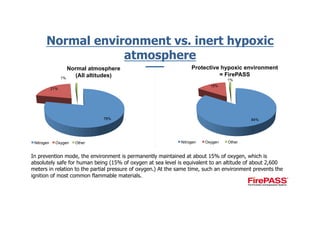

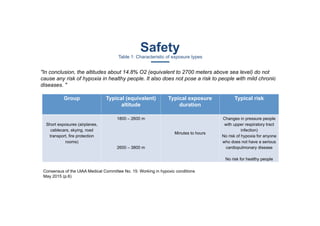

3) Maintaining oxygen levels equivalent to an altitude of 2,600 meters provides permanent fire protection without risk to health, as the hypoxic air is inhaled. FirePASS systems are suitable for protecting IT infrastructure, archives, industrial facilities and more.