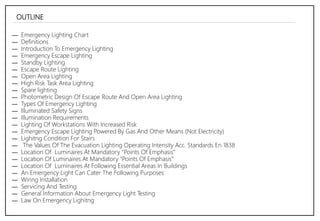

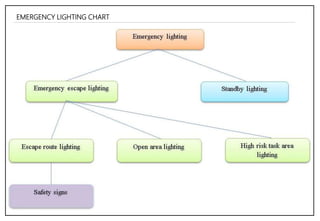

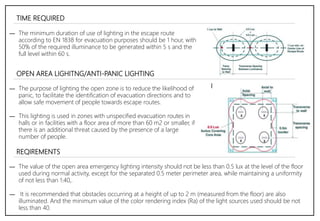

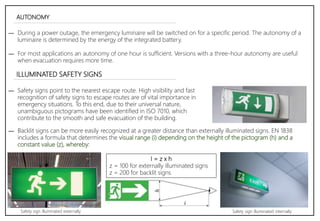

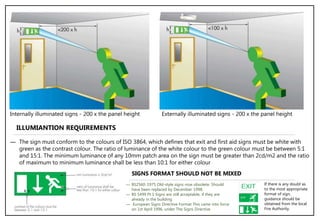

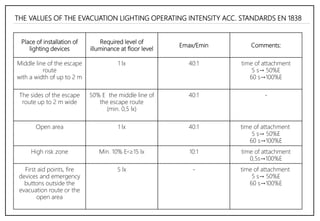

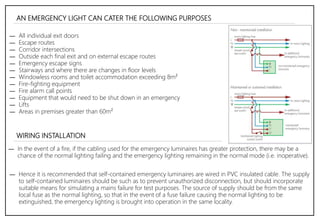

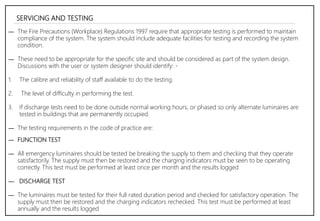

The document outlines comprehensive guidelines on emergency escape lighting systems, including definitions, types, installation standards, and maintenance procedures necessary for ensuring safe evacuations in emergencies. Key components discussed include escape route lighting, open area and high-risk task area lighting, as well as specific regulations and requirements for illuminated safety signs. The document emphasizes the importance of compliance with occupational health and safety standards, building codes, and fire regulations.