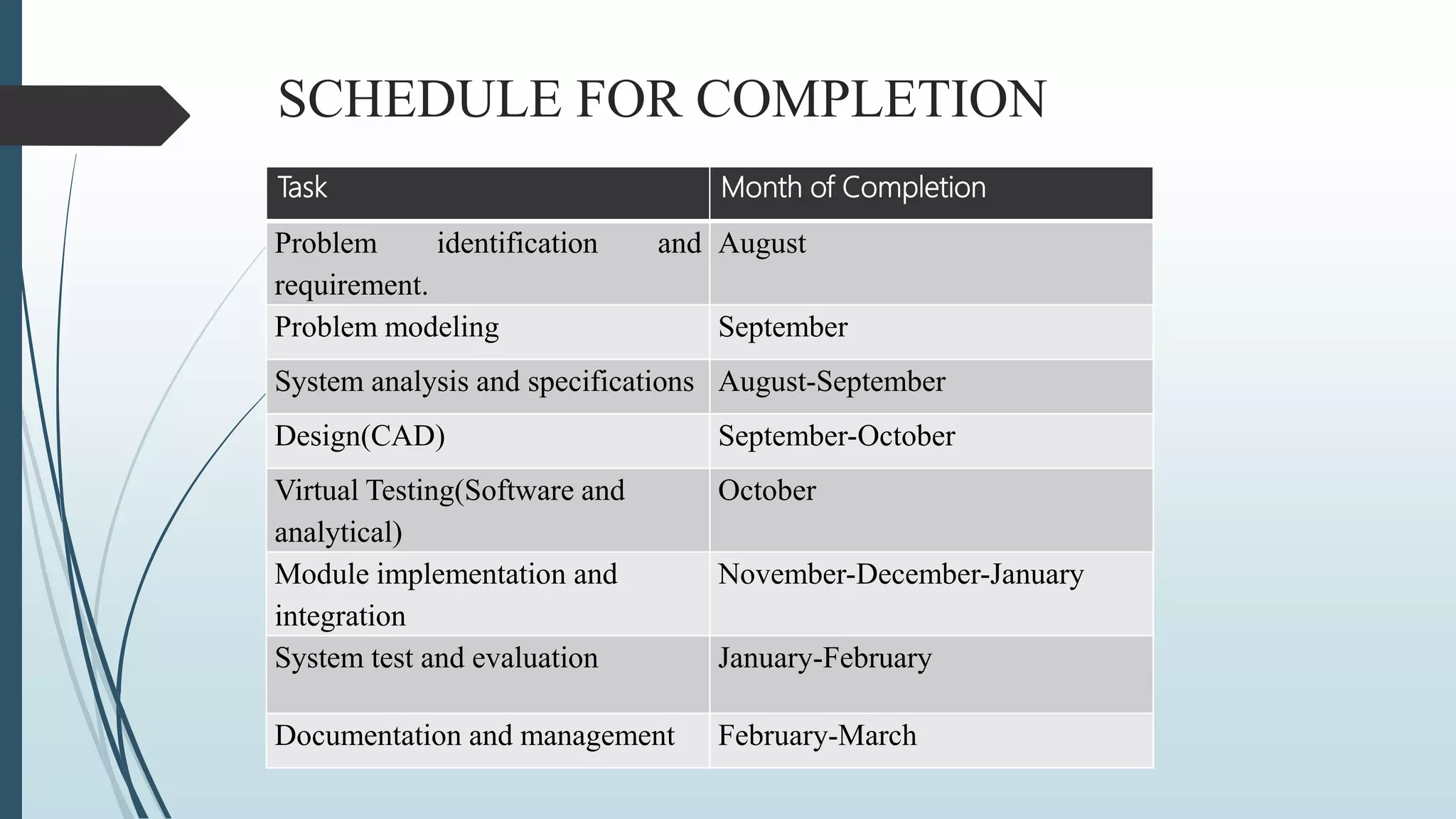

The document outlines a final year project by students from the Department of Mechanical Engineering focused on the design and development of an automatic wet tissue paper packing machine sponsored by JKC Automobile Engineering. The project aims to automate the currently semi-automatic process to enhance production efficiency, incorporating both mechanical and electronic components within a mechatronics system. A detailed schedule for project completion is included, covering all phases from problem identification to documentation.