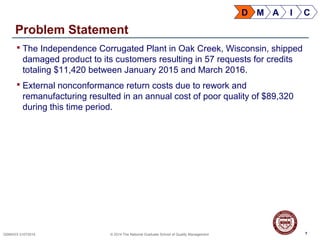

This document provides information about a project being conducted by Team Independence at Independence Corrugated to address product loading damage. It introduces the team members and champions. It describes the company's history and mission. It presents the problem statement of damaged products being shipped resulting in customer credits. It outlines the Define and Measure phases of the DMAIC process used, including data collection plans, surveys, analyses of damage by shift and customer, and monitoring of damage locations.