1. Vandex products provide long-lasting waterproofing protection for basement structures when properly applied, forming an integral part of the concrete structure.

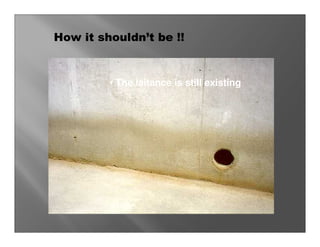

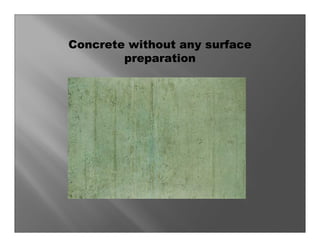

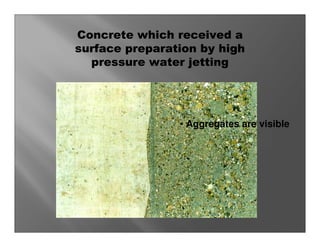

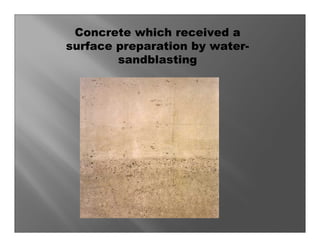

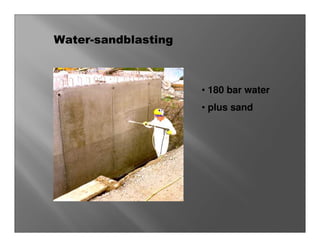

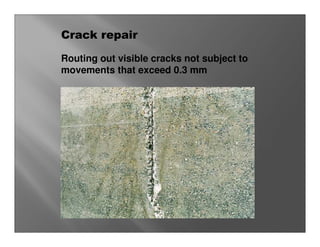

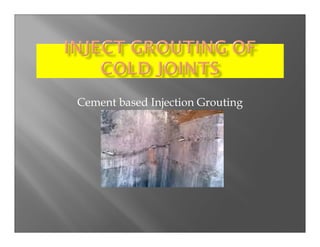

2. Their application requires thorough surface preparation to remove laitance and contaminants from the concrete surface.

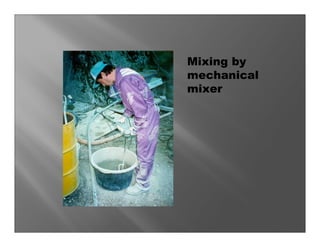

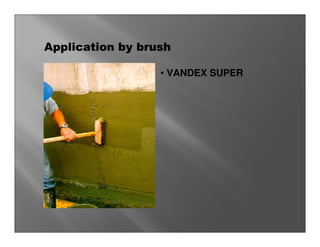

3. Vandex products must be precisely mixed and applied according to the technical data sheet, with careful control of material consumption, temperature conditions during application, and proper curing afterwards.