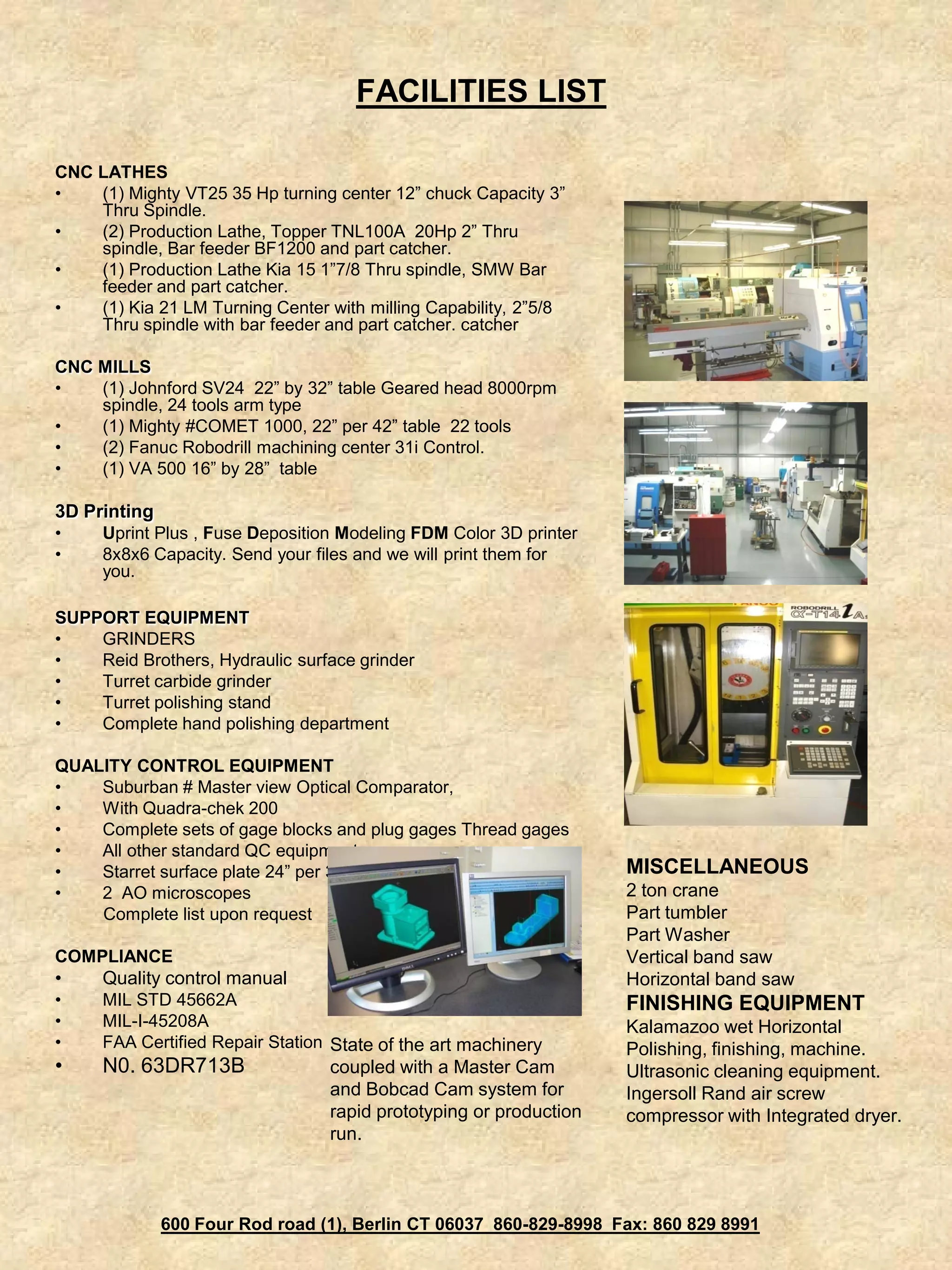

This document lists the facilities' equipment, including CNC lathes and mills, a 3D printer, support equipment like grinders and quality control tools, and miscellaneous items like band saws, a tumbler, and compressor. The facilities have state-of-the-art CNC machines from brands like Mighty, Topper, and Kia coupled with CAM software for rapid prototyping and production. Quality control equipment includes an optical comparator, gage blocks, and thread gages.