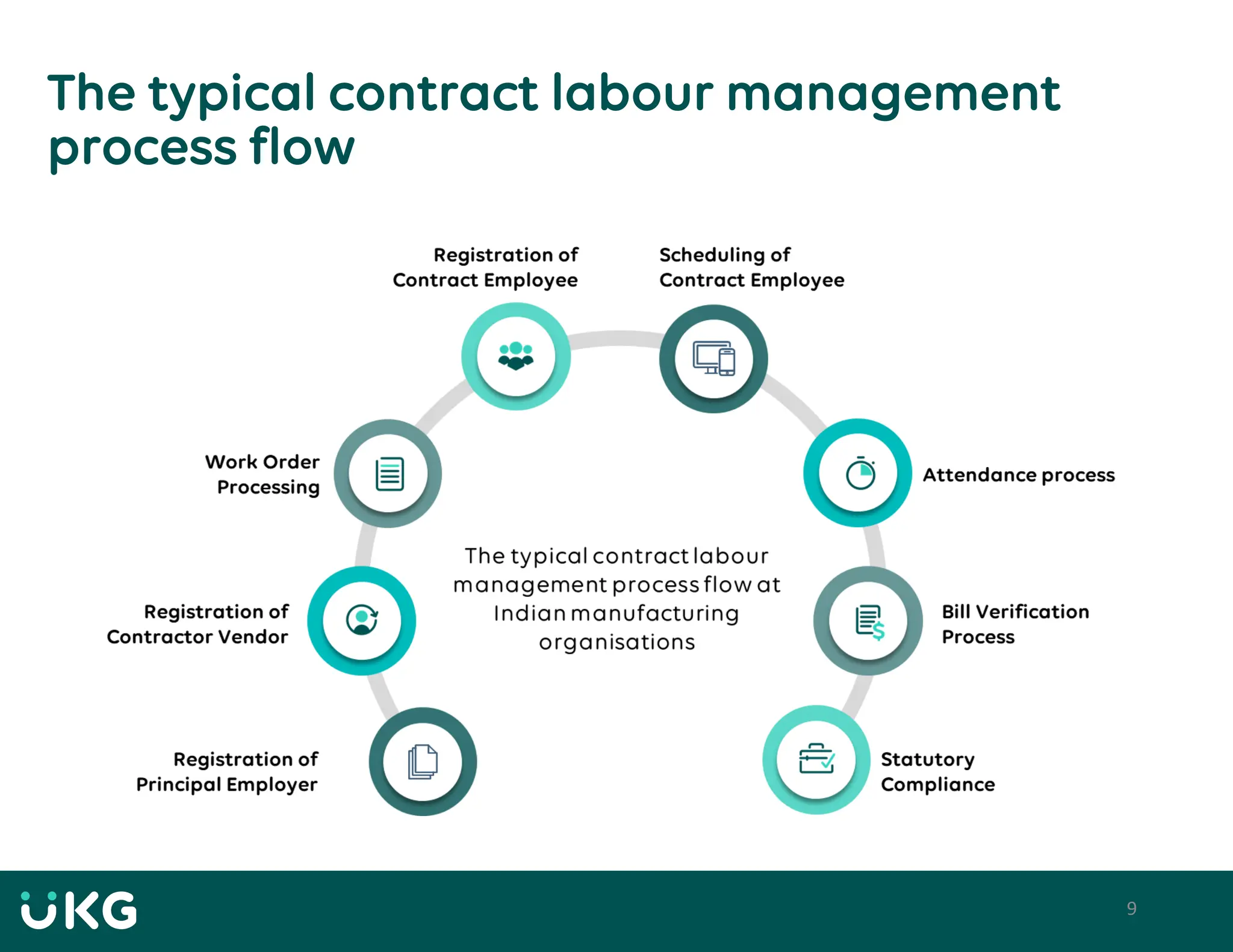

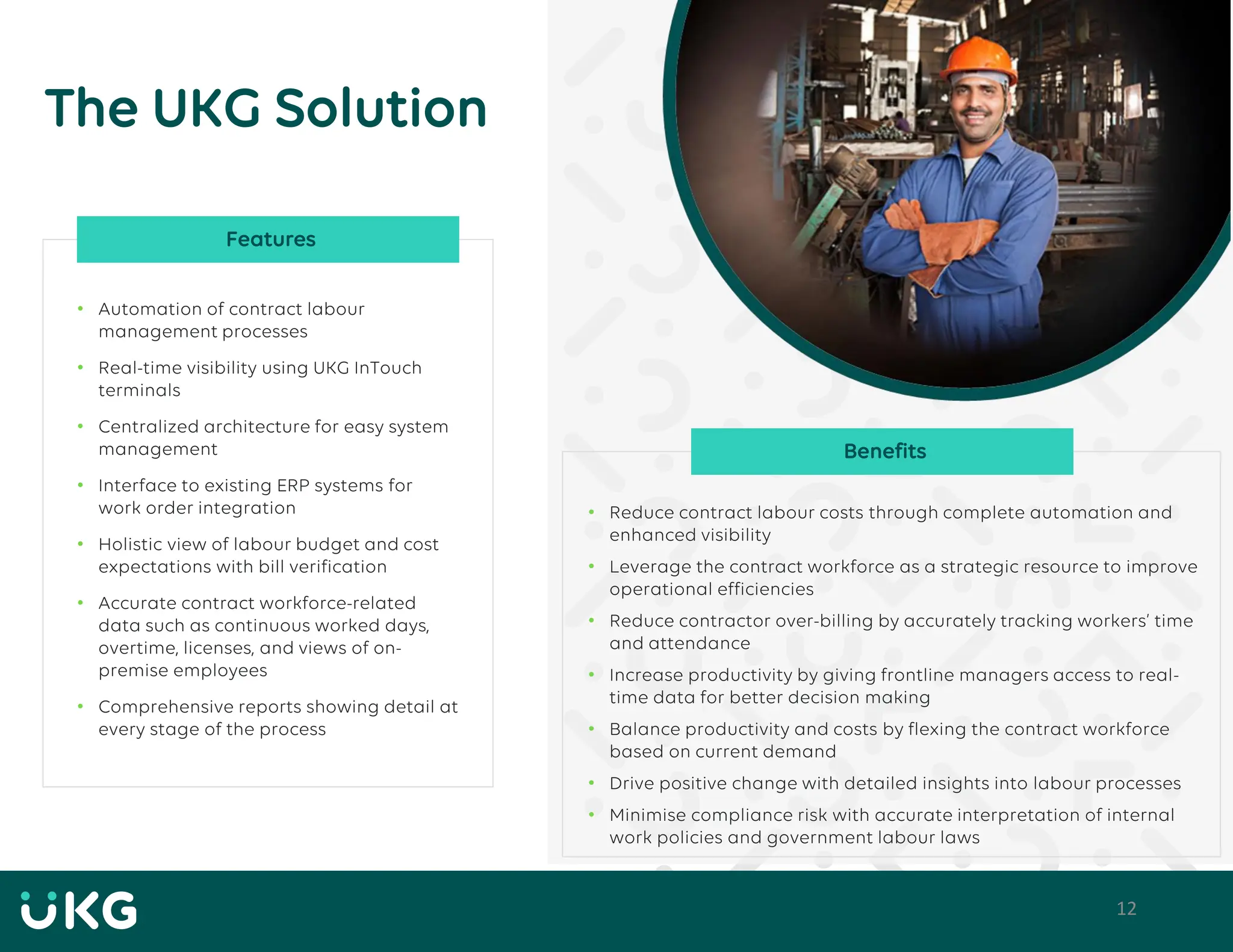

A single, centralized contract workforce management system can help Indian manufacturers achieve cost savings and operational efficiencies by managing their contract workforce more effectively. Current point solutions are no longer sufficient due to challenges like contractor reluctance, paper-based processes, workforce churn, and compliance issues. Manufacturers need a system that automates the entire contract workforce management process, provides real-time visibility across locations, ensures compliance, and interfaces with ERP systems to drive data consistency and cost control. This will help manufacturers address the growing complexity of contract labor management.