Garrett Griffith completed an internship at Evergreen Packaging over the summer. He worked on three projects:

1) Compiling roll data from the paper machine into an Excel spreadsheet for future reference. This involved gathering information from drawings and SAP.

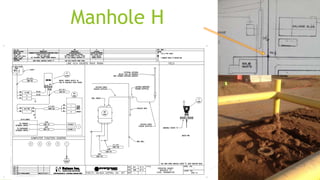

2) Installing flowmeters to measure water usage around the mill. Issues arose with transmitter ranges and valve positions but were eventually resolved.

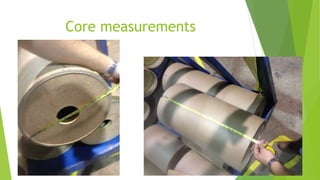

3) Conducting a study on core shrinkage by measuring cores over time in different environments and correlating shrinkage to cut length. The results will help adjust cutting practices.

Garrett gained valuable experience applying his engineering education to real-world problems and learned many lessons about project management, troubleshooting, and mill operations.