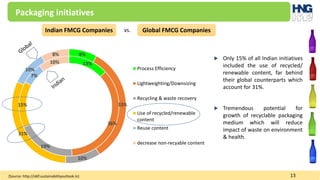

This document provides a history of glass packaging from ancient Egypt to modern times. It discusses how glass was first made over 3500 BC and highlights key developments such as glass blowing starting in Syria in 1500 BC. The document outlines the raw materials used to make glass and describes glass's physical and chemical properties that make it suitable for packaging. It compares glass packaging favorably to other materials in terms of safety, recyclability, and maintaining product quality. The document discusses initiatives to increase recycled glass usage and reduce environmental impact. It shares customer perspectives on preferring glass for its purity and sustainability. Finally, it outlines developments in glass packaging technology to make bottles lighter, stronger, and better.