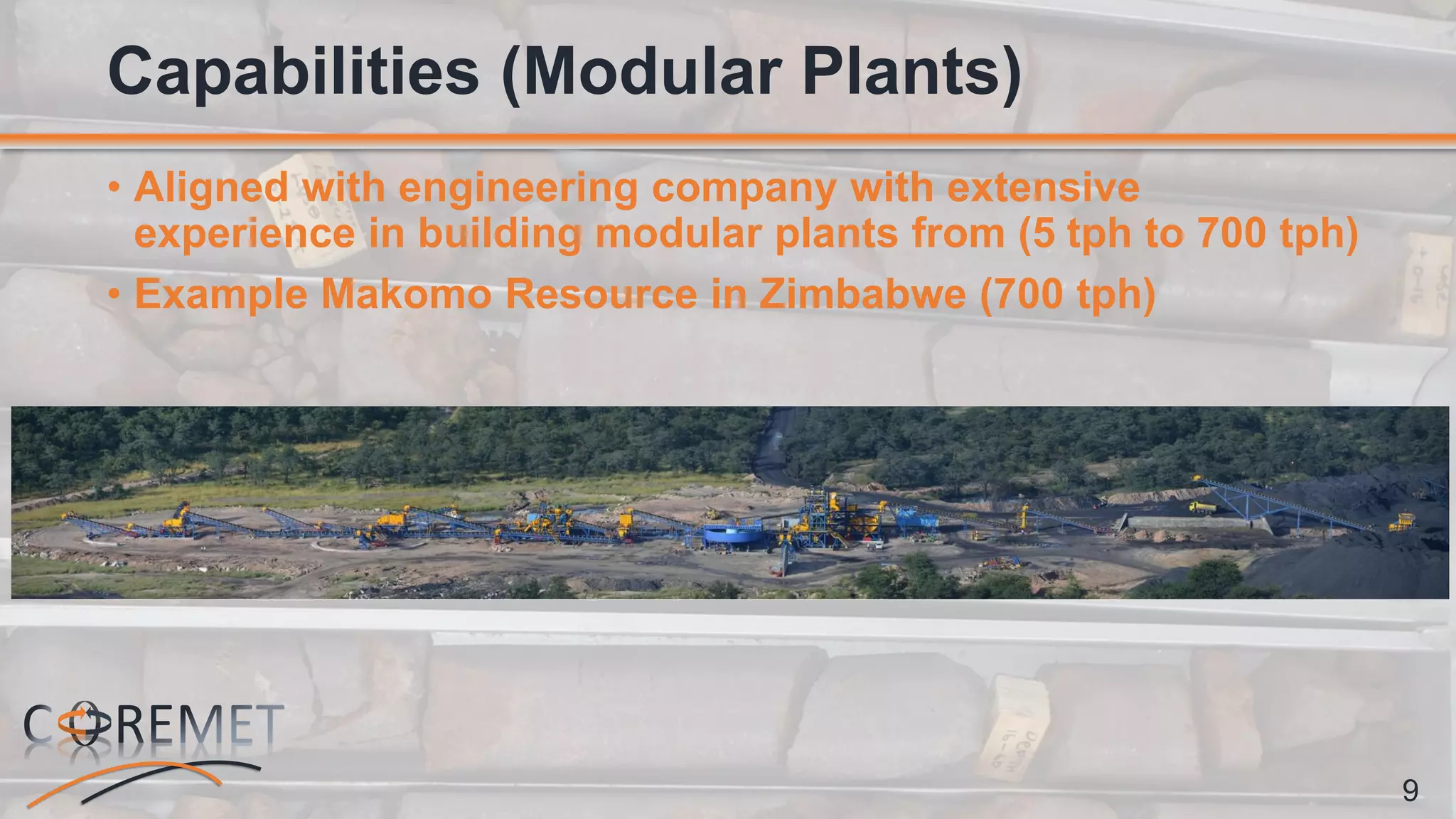

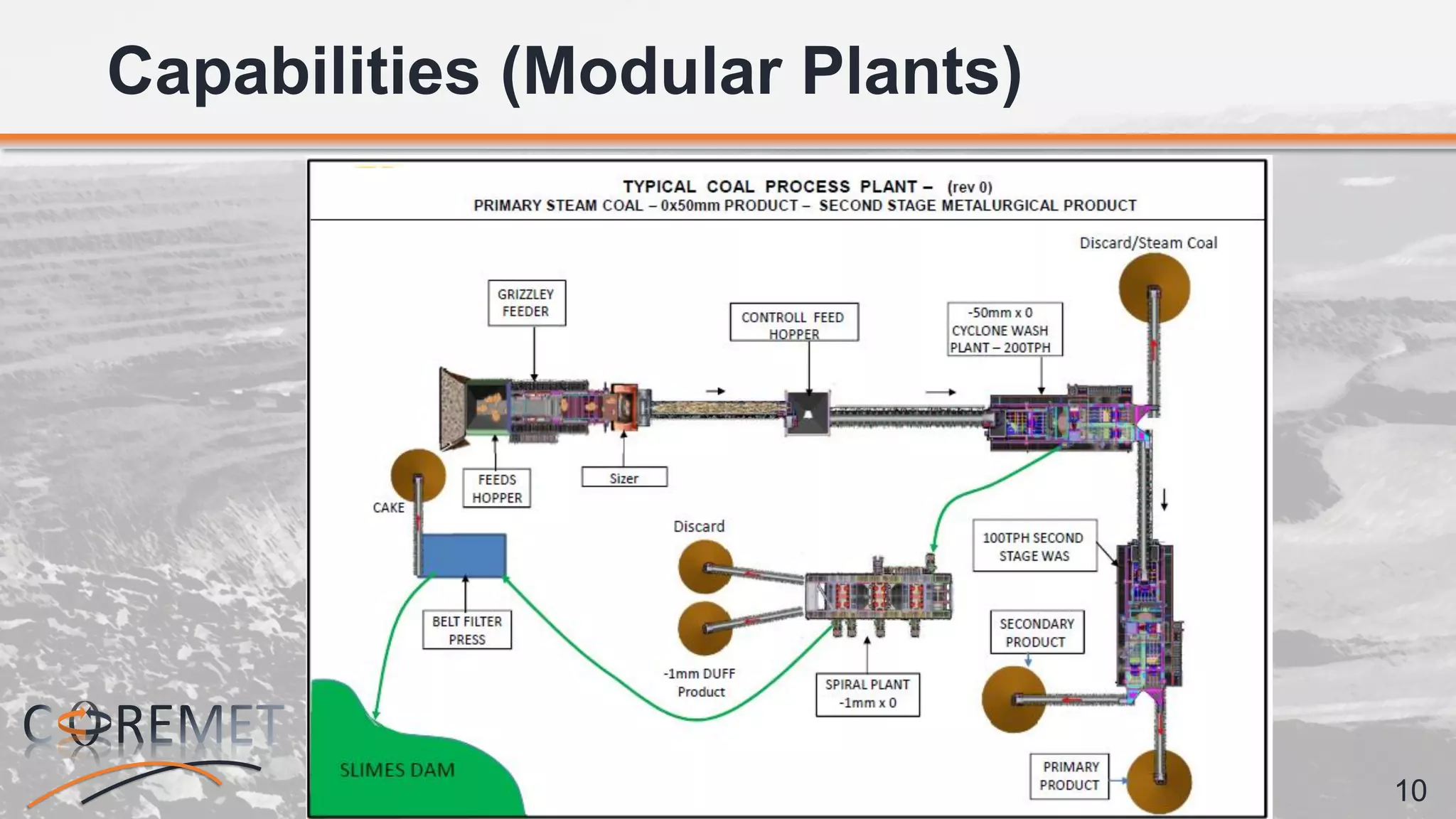

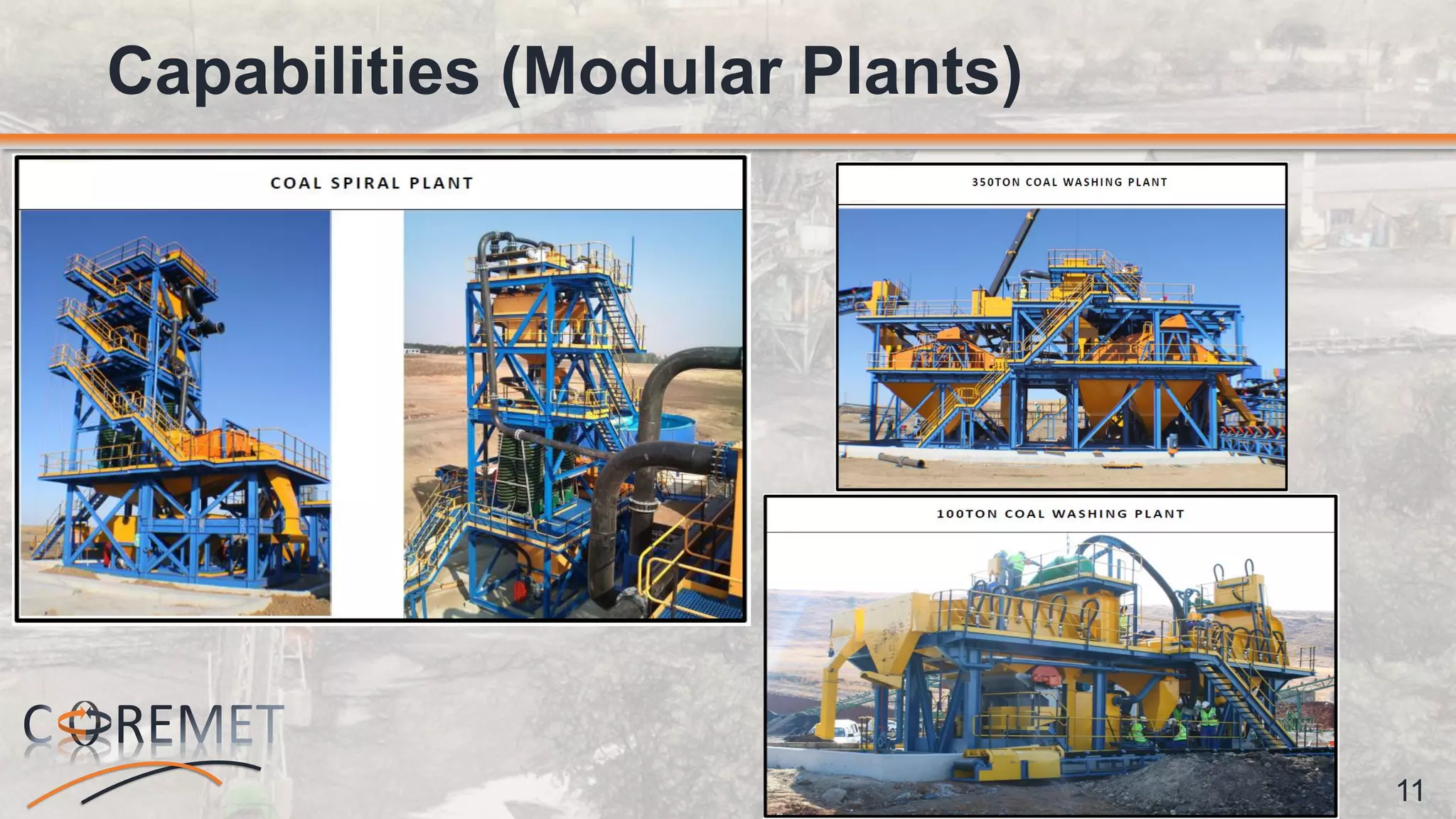

CoreMet is a newly established mineral processing company with over 20 years of experience in metallurgical testing, plant optimization, and modular plant design, construction, and operation. The company offers consulting services, metallurgical test work, modular processing plants, plant optimization, and a focus on dry processing, fines processing, and zero effluent technologies based on their technical experience and capabilities.