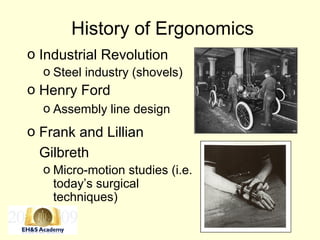

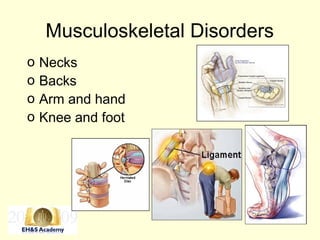

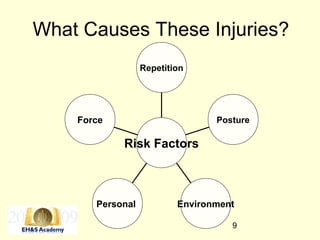

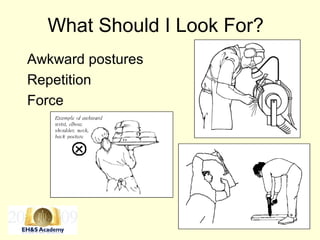

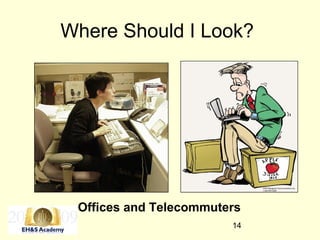

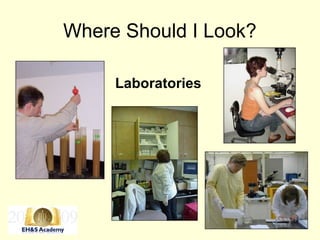

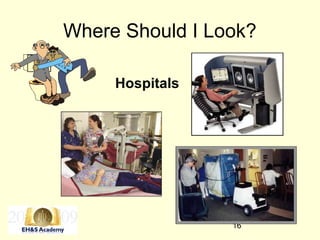

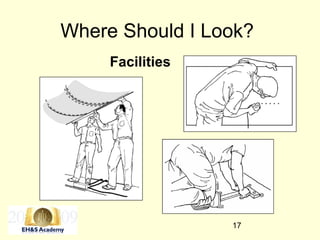

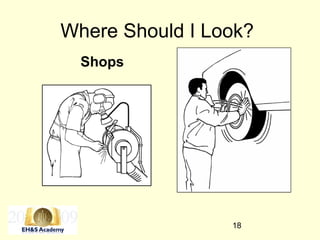

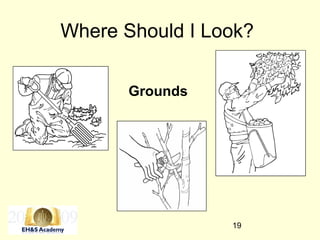

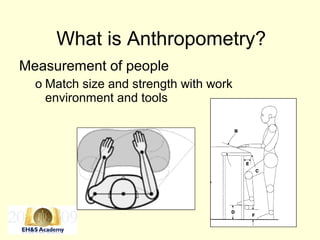

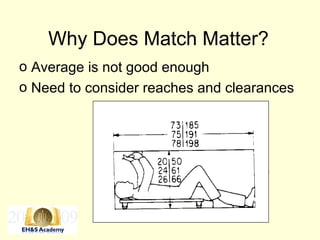

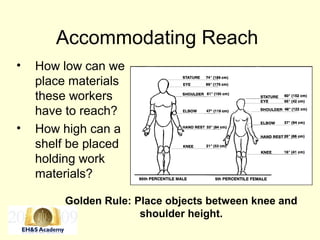

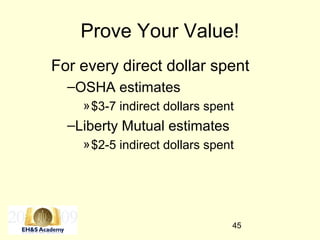

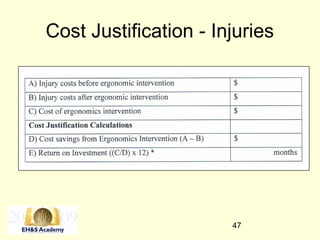

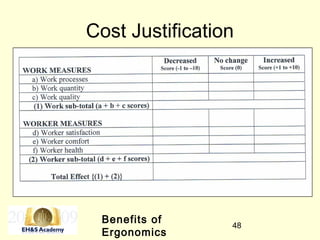

This document provides an overview of ergonomics and strategies for improving ergonomics. It discusses the history and development of ergonomics from the Industrial Revolution to today. Key points covered include defining ergonomics as matching jobs, tools, and workplaces to workers; common causes of musculoskeletal injuries like force, posture, and repetition; evaluating areas like offices, laboratories, and hospitals for ergonomic risks; and interventions like lifting equipment, adjustable workstations, and training to reduce injuries and increase productivity. The document emphasizes that small ergonomic changes can yield large cost savings by preventing injuries and improving employee health, satisfaction and retention.