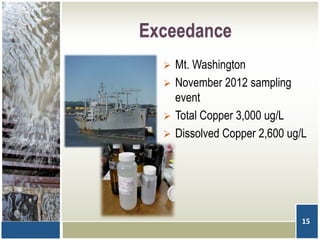

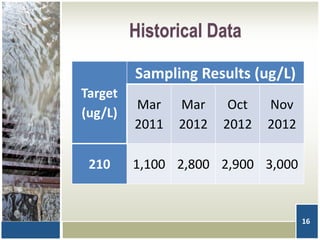

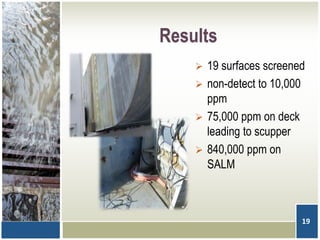

The document outlines developments in industrial stormwater regulations, focusing on California's new Industrial General Permit and a draft Multi-Sector General Permit, which include numeric action levels and public accessibility requirements. It discusses three case studies highlighting stormwater management challenges and solutions across various sectors, emphasizing technical considerations and compliance needs. The document also addresses broader regulatory trends and issues relevant to industrial stormwater discharges.