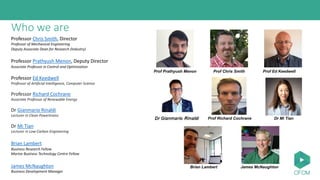

The Centre for Future Clean Mobility at the University of Exeter is focused on developing innovative zero emissions powertrain technology for cleaner transport across various sectors, including marine, rail, and defense. With over 30 industry partnerships and government support, the centre aims to lead advancements in smart mobility and meet net zero targets by 2050. Current projects include electric powertrains for road-rail vehicles, fully electric ferries, and smart portable chargers to enhance the EV infrastructure.