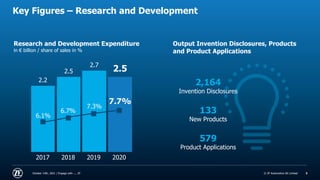

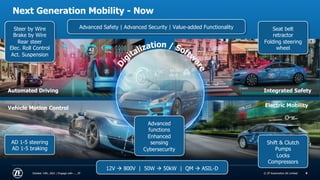

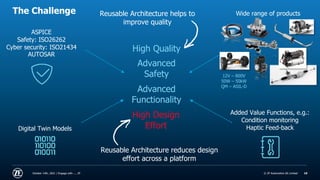

The document outlines ZF's financial overview for 2020, highlighting €32.6 billion in sales and significant investments in research and development. It also details ZF's sustainability strategy aiming for 2030 goals, such as using 100% green electricity and incorporating 50% recycled materials in products. Furthermore, it discusses ZF's initiatives in electric mobility and advanced safety features as part of next-generation mobility solutions.