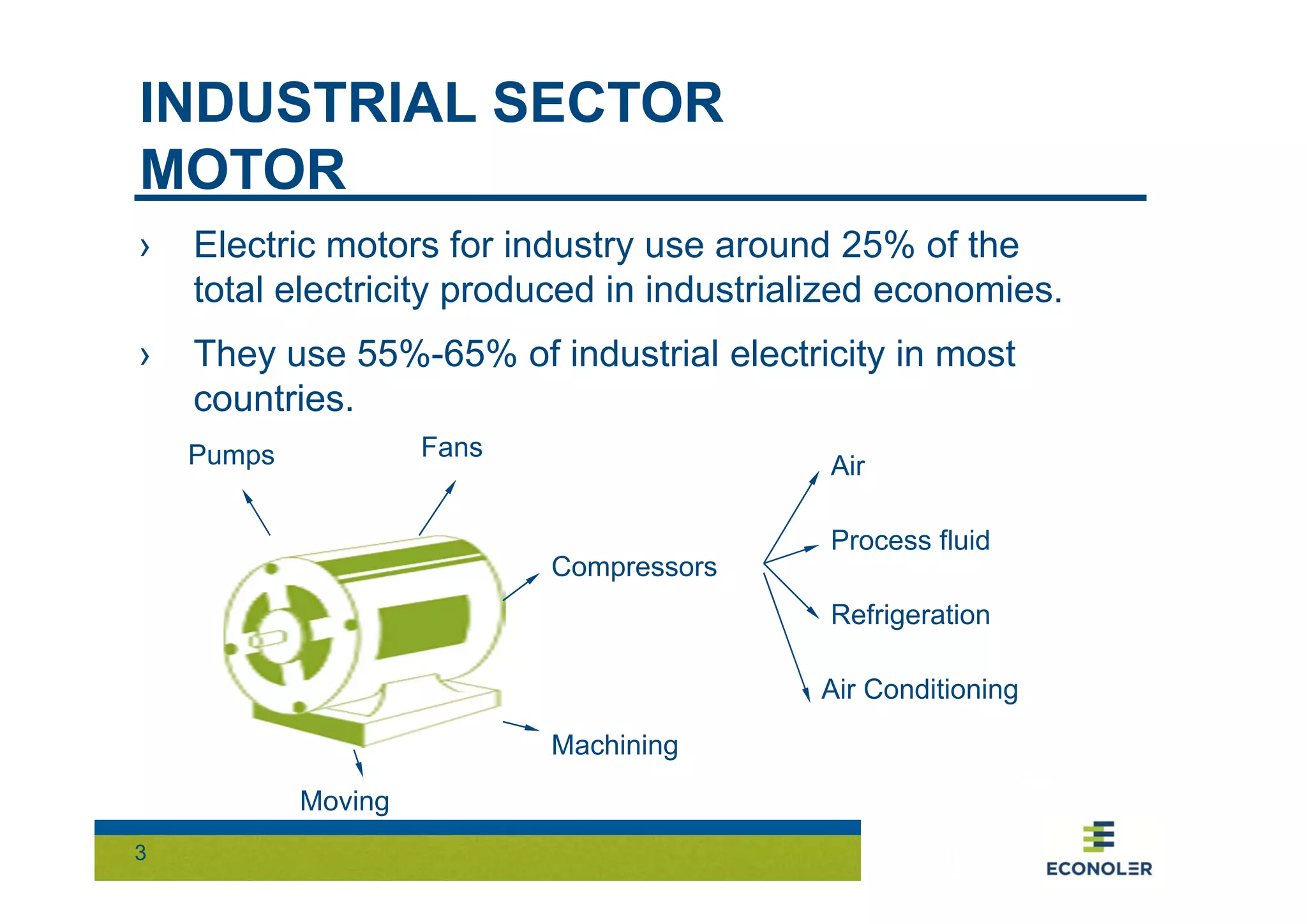

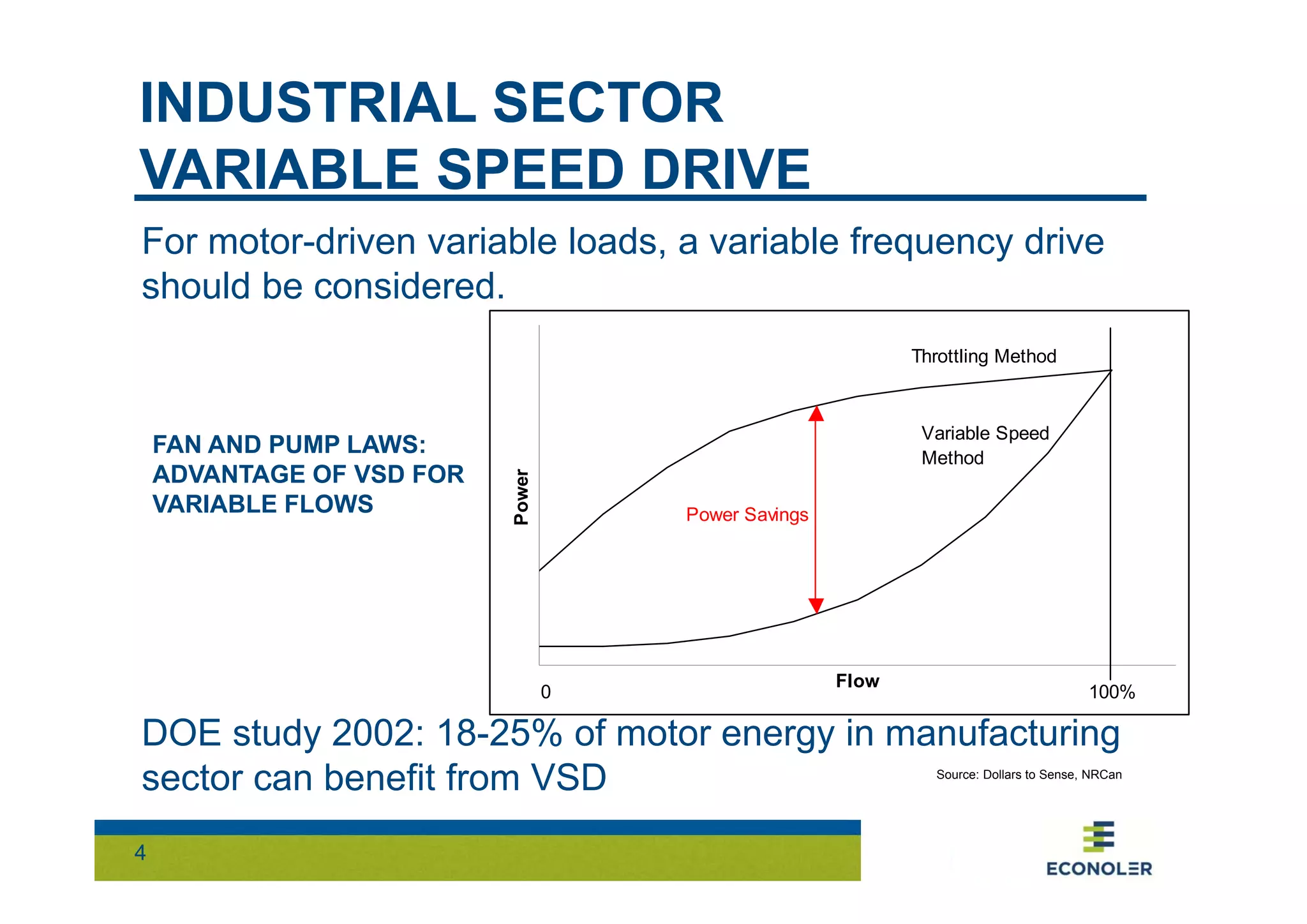

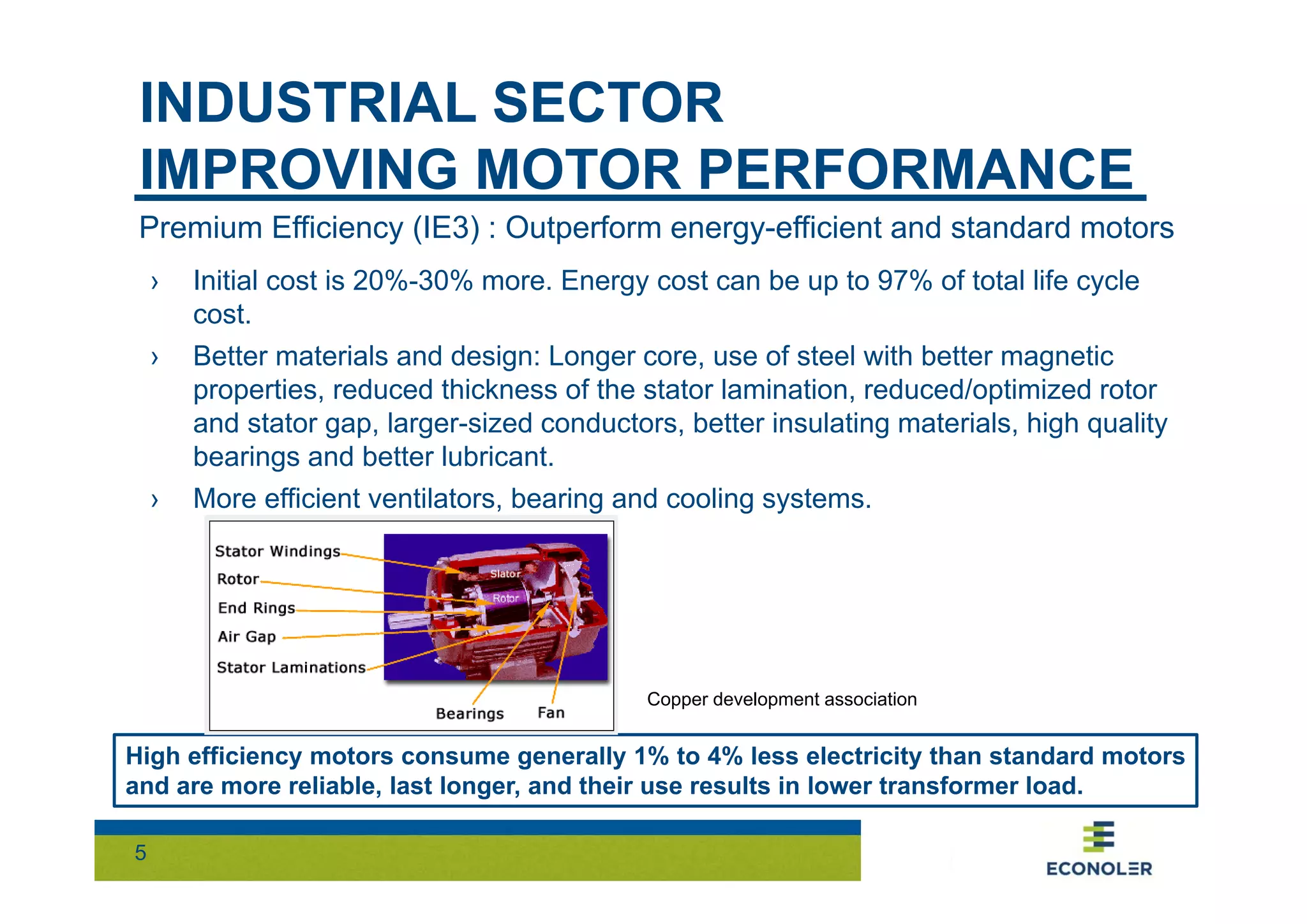

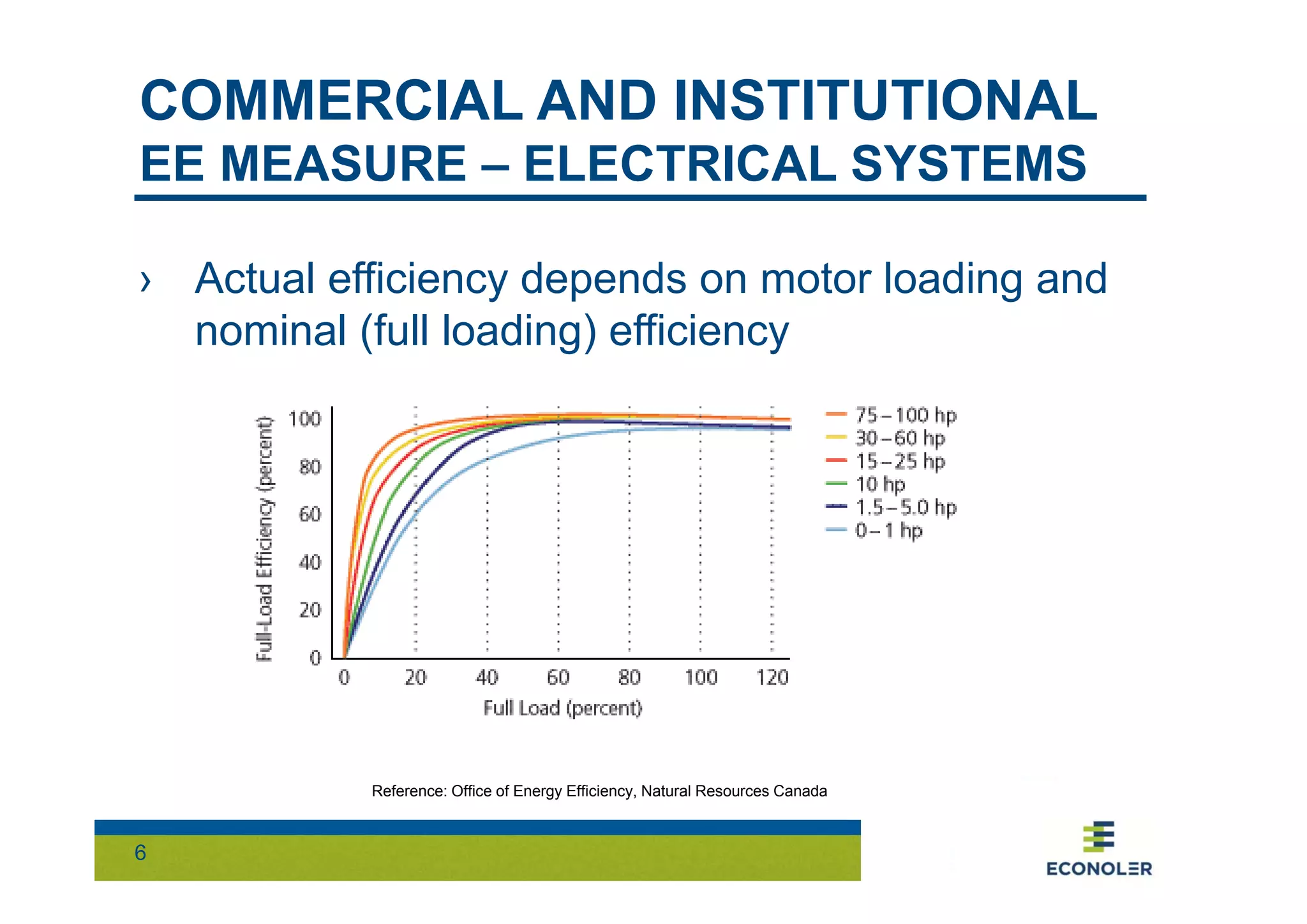

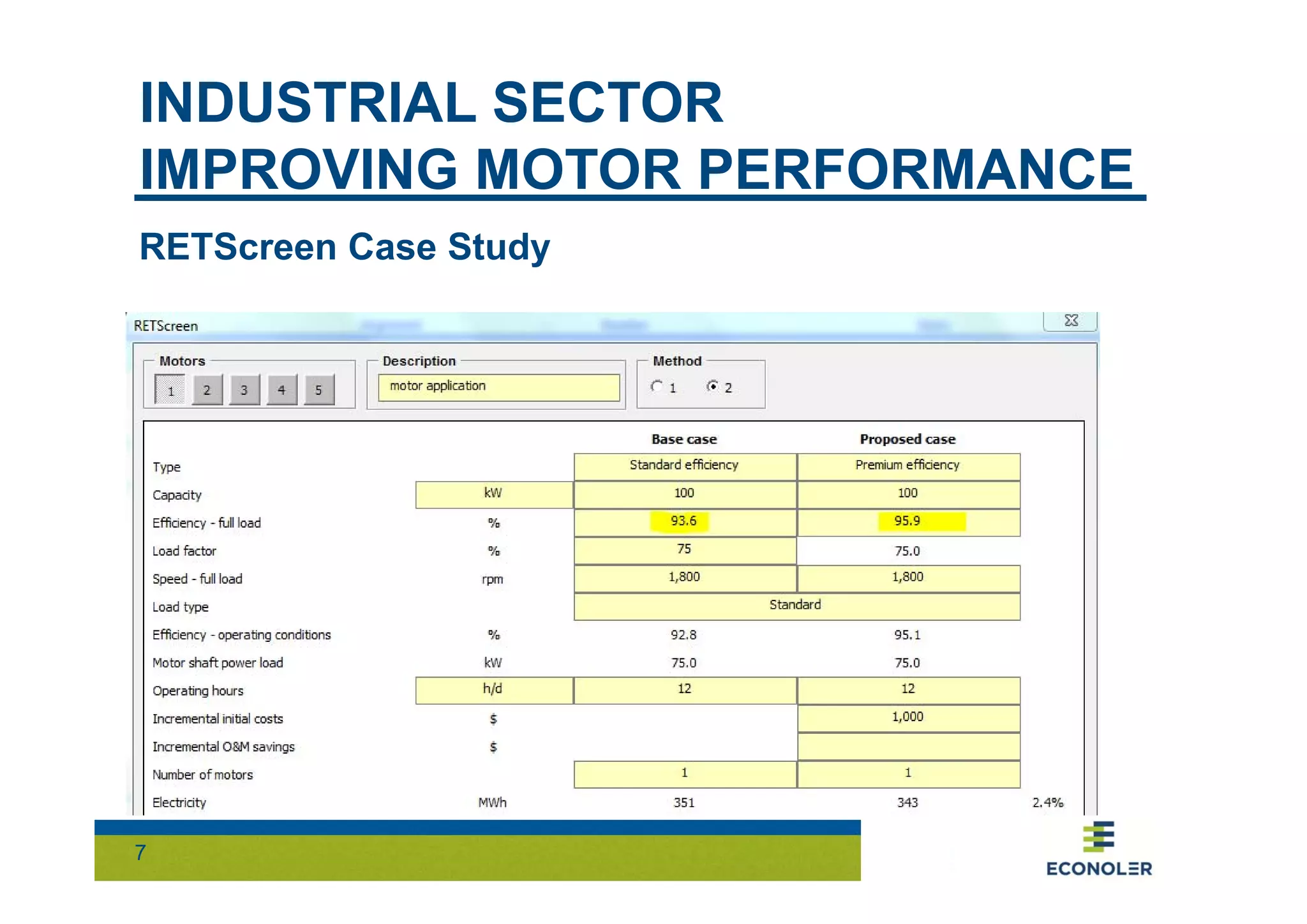

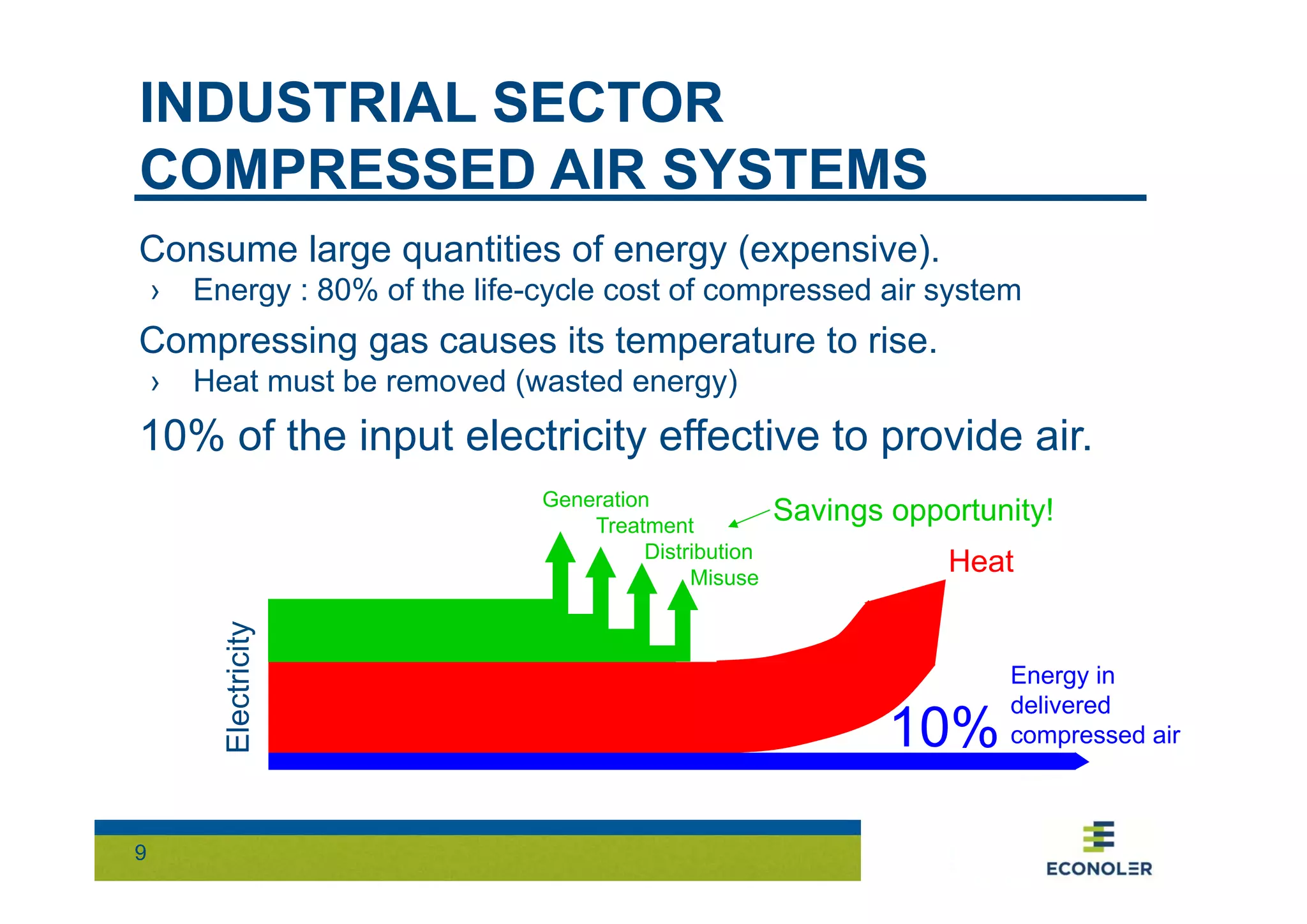

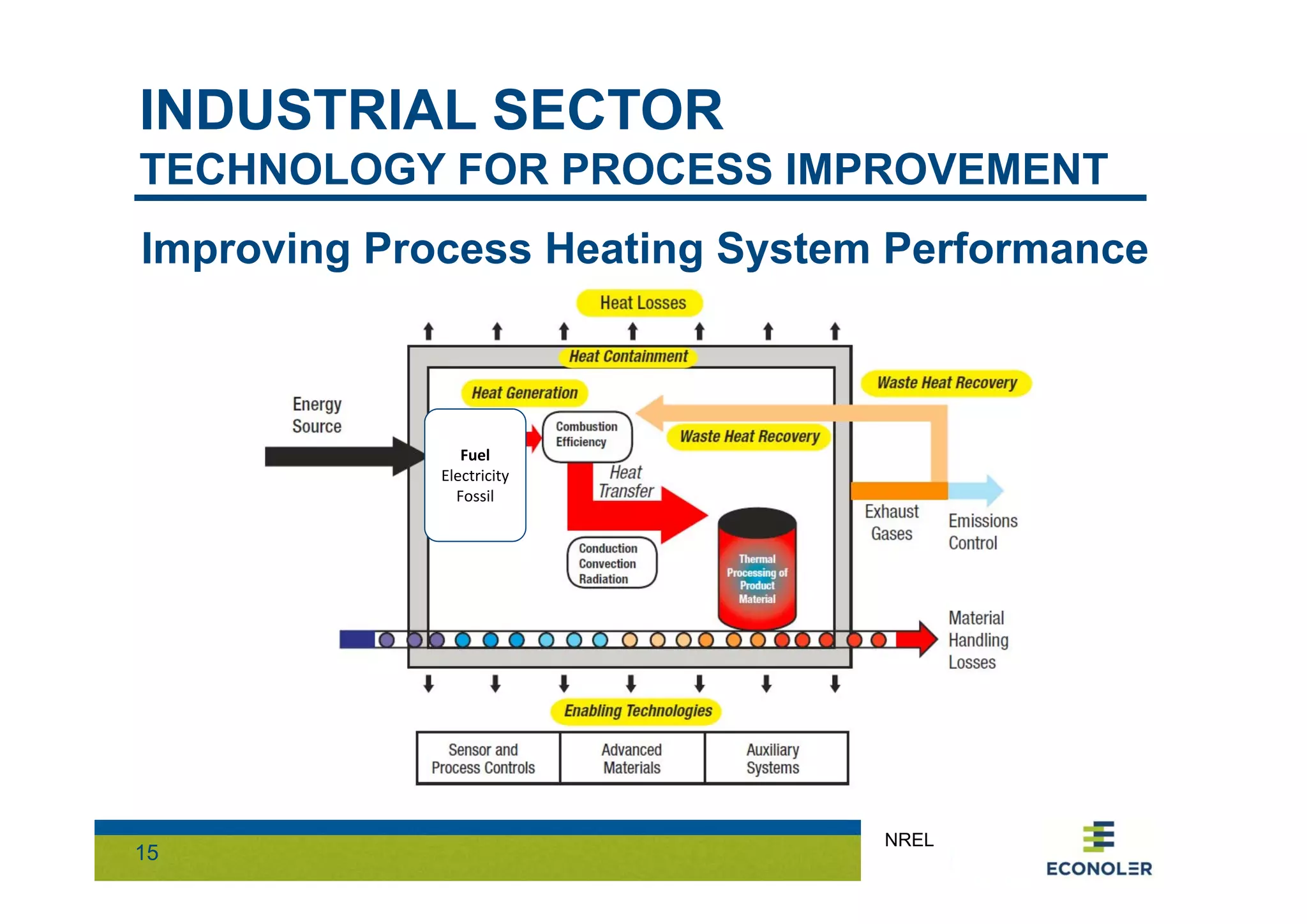

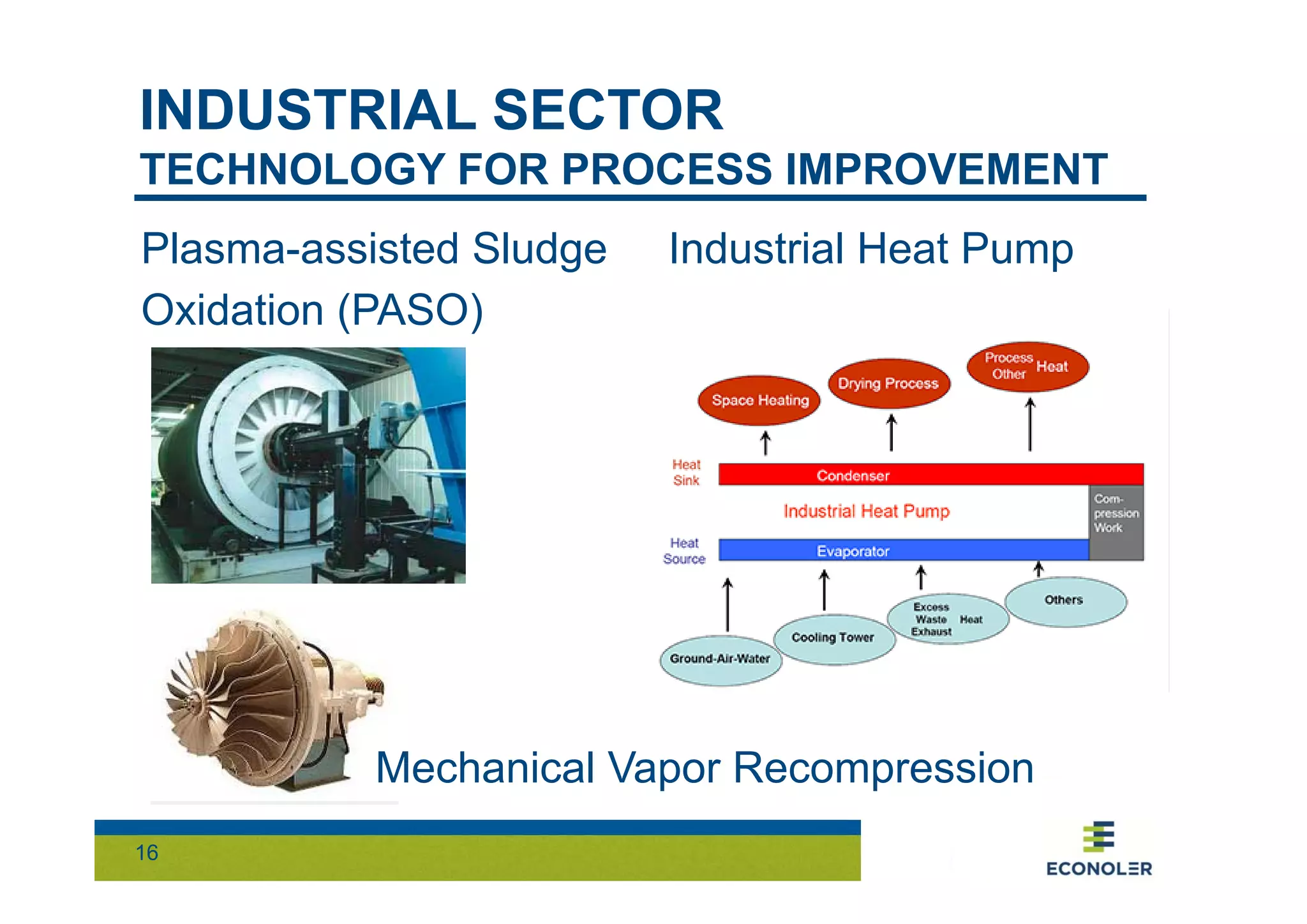

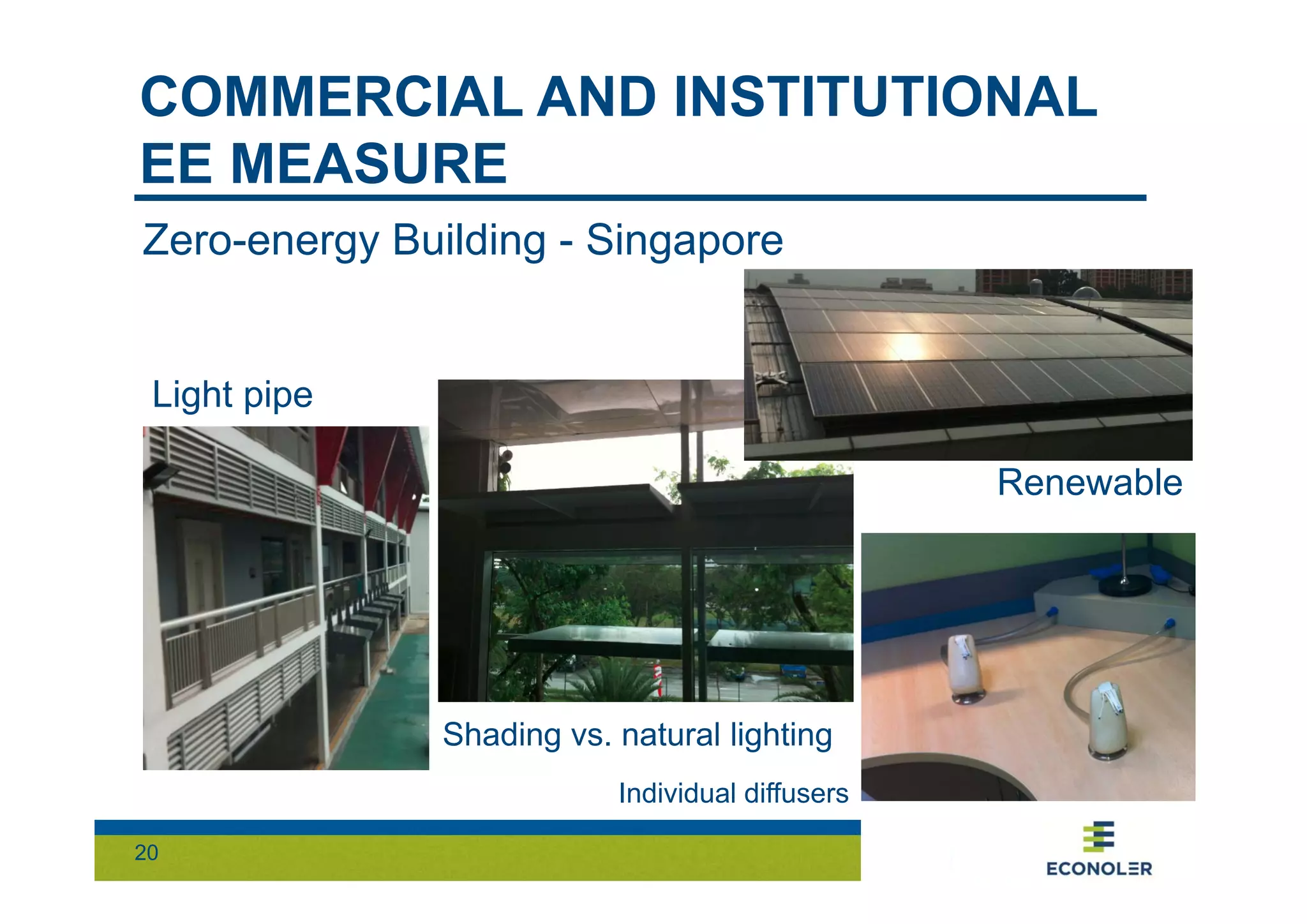

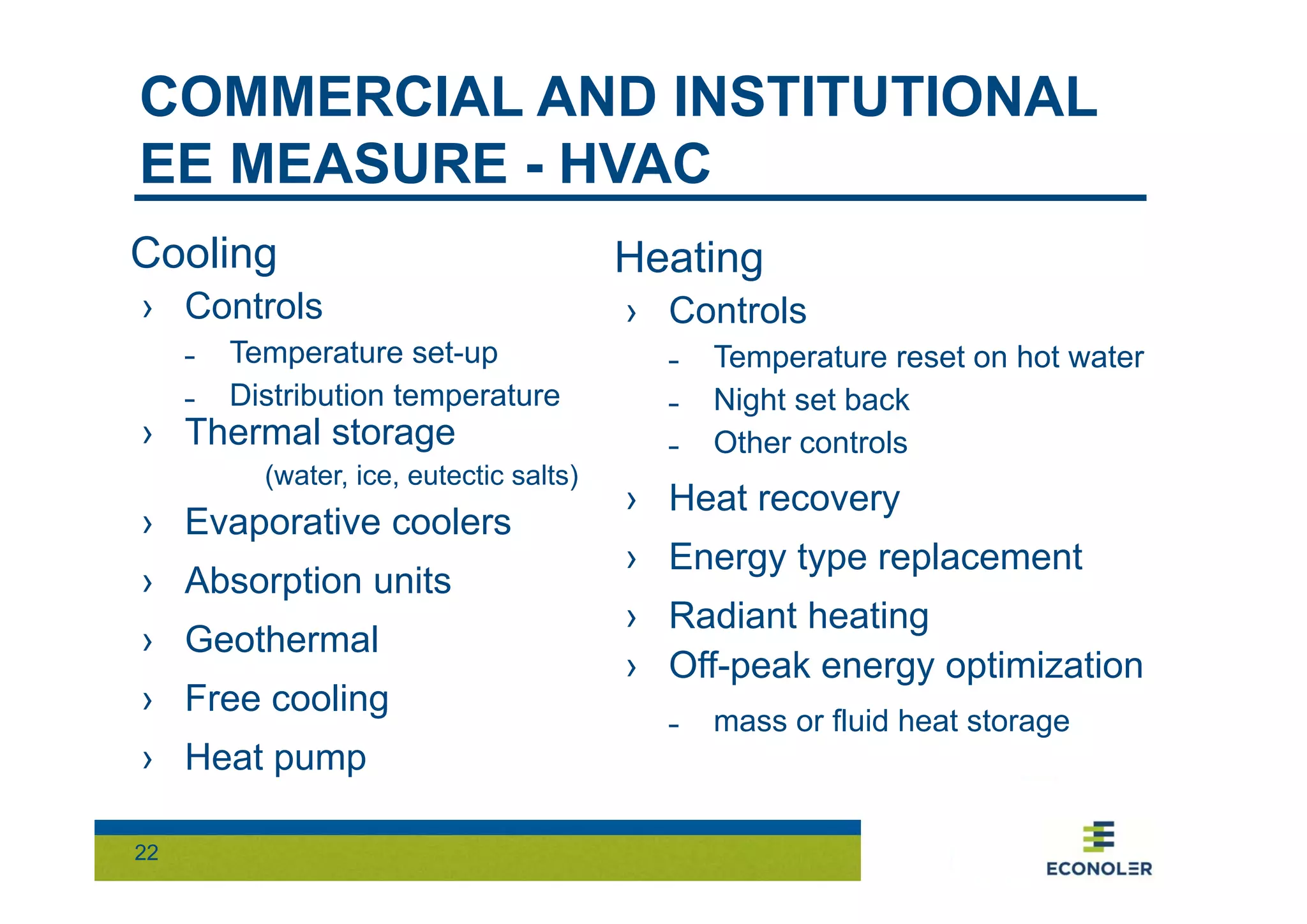

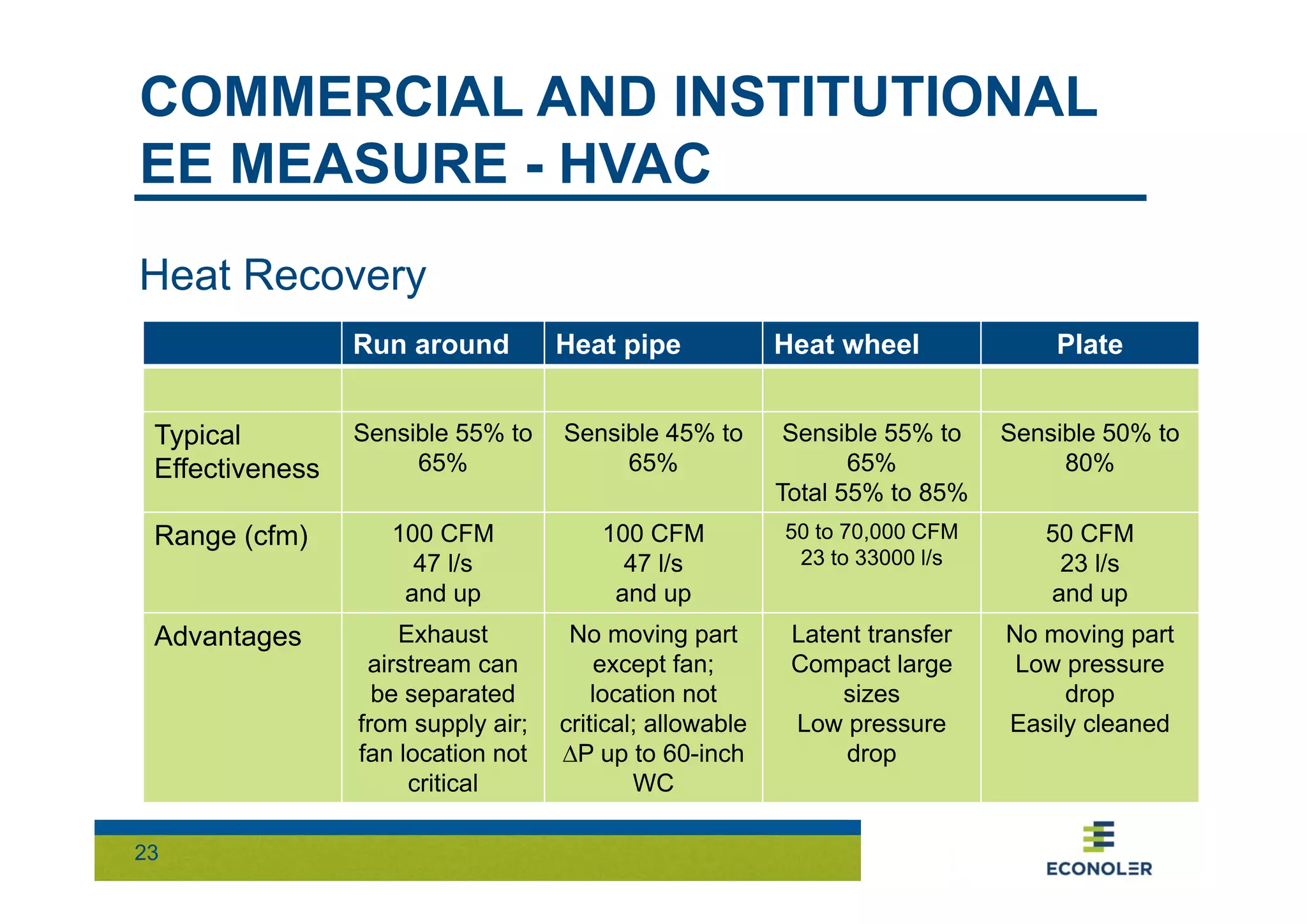

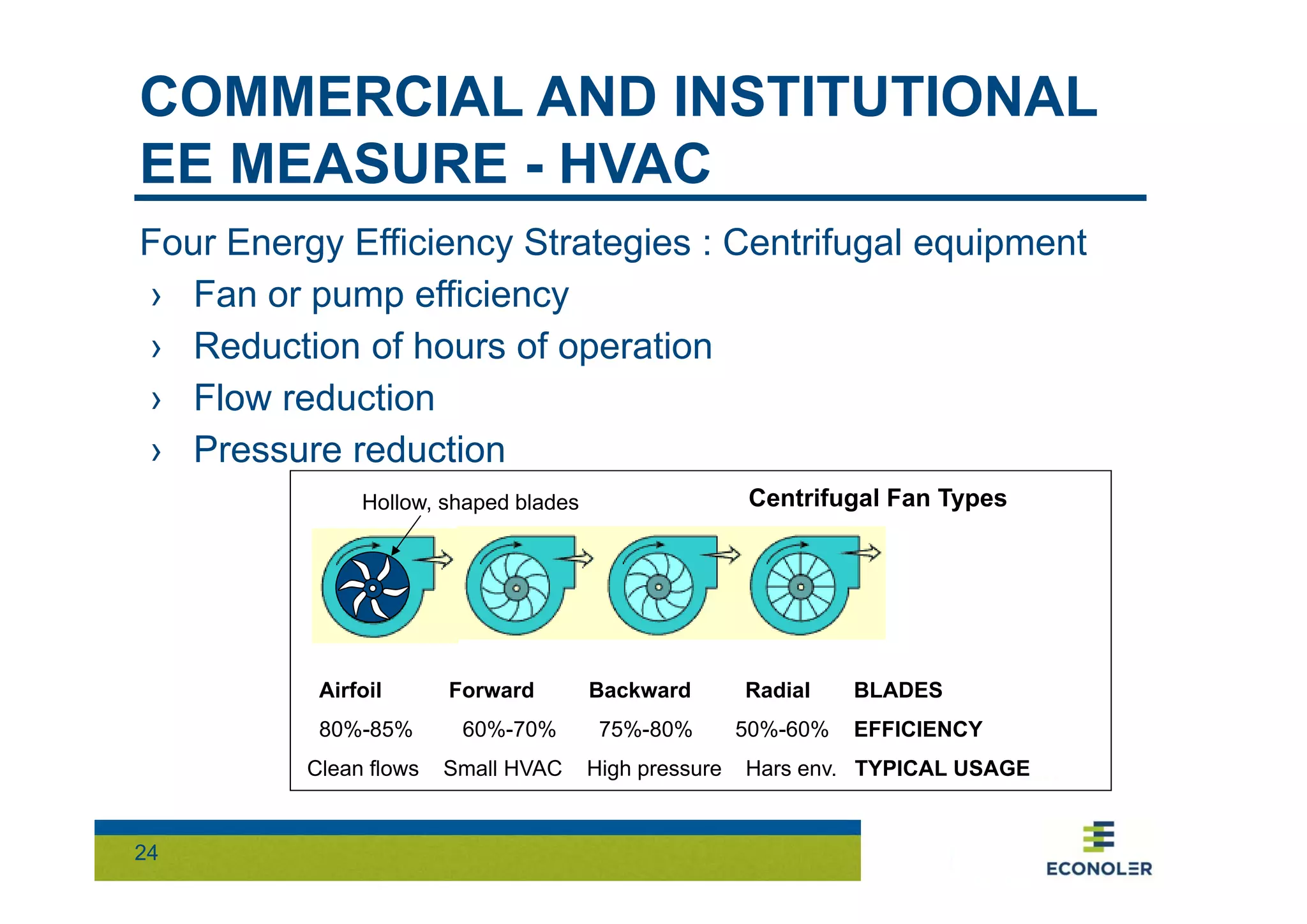

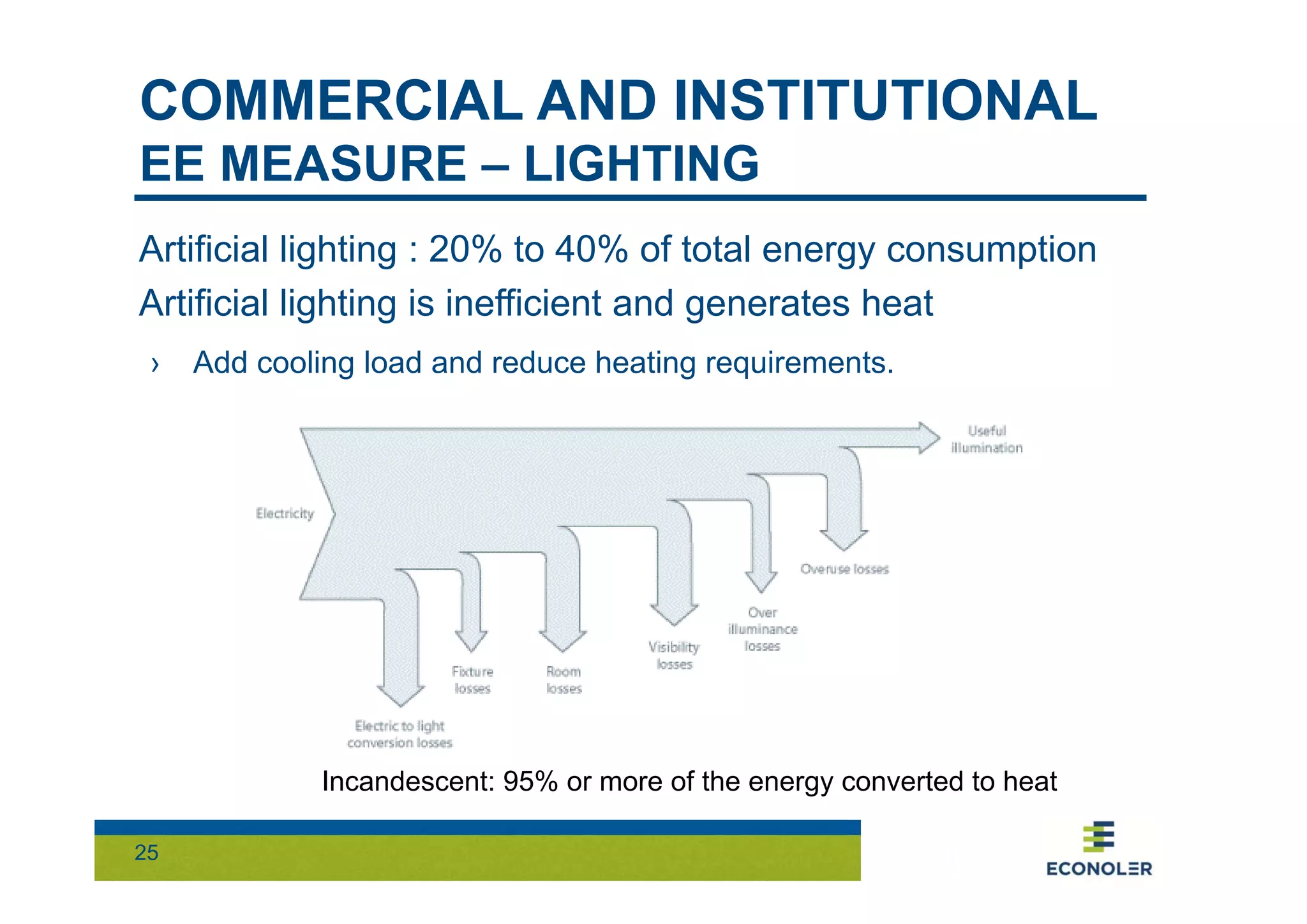

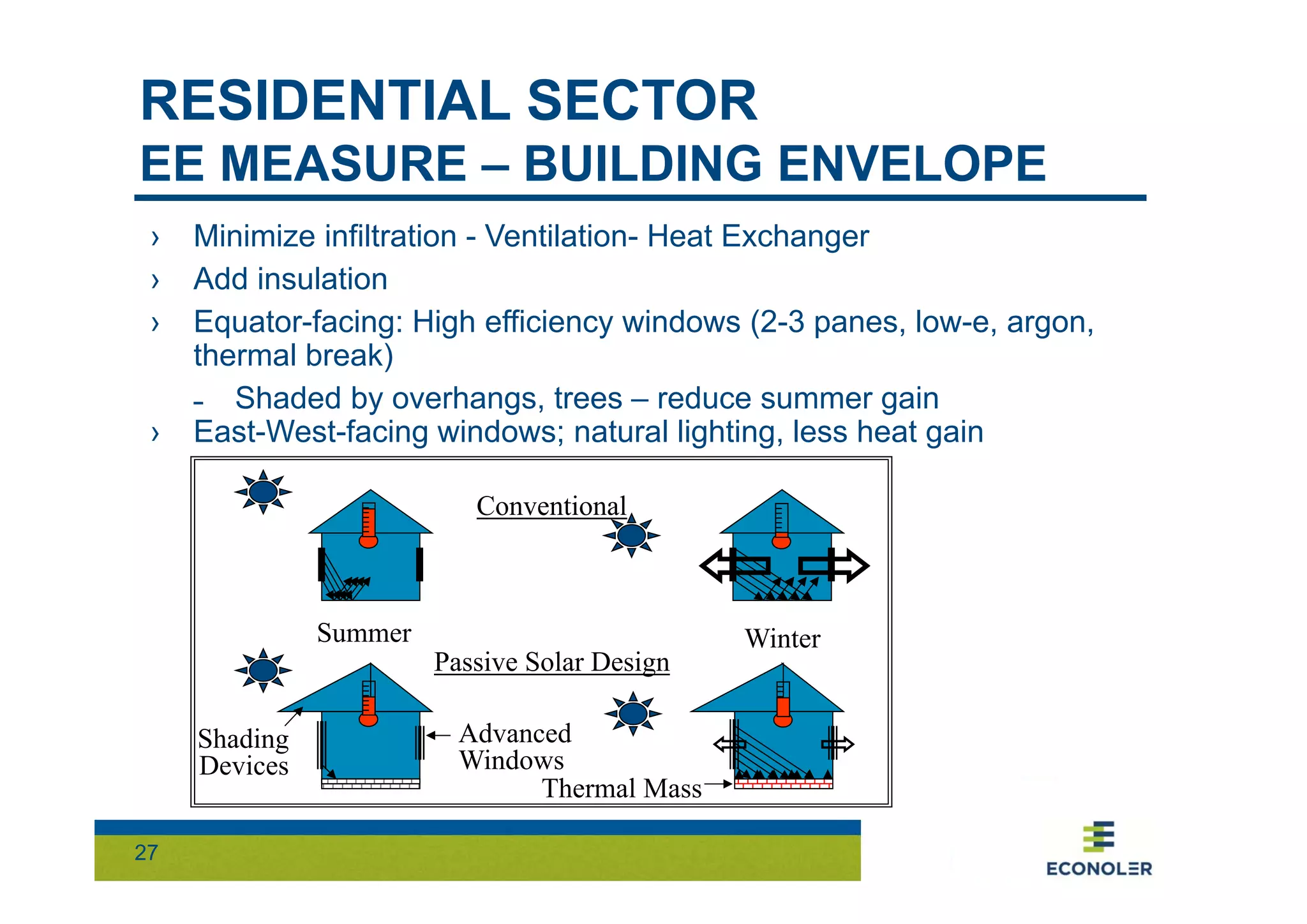

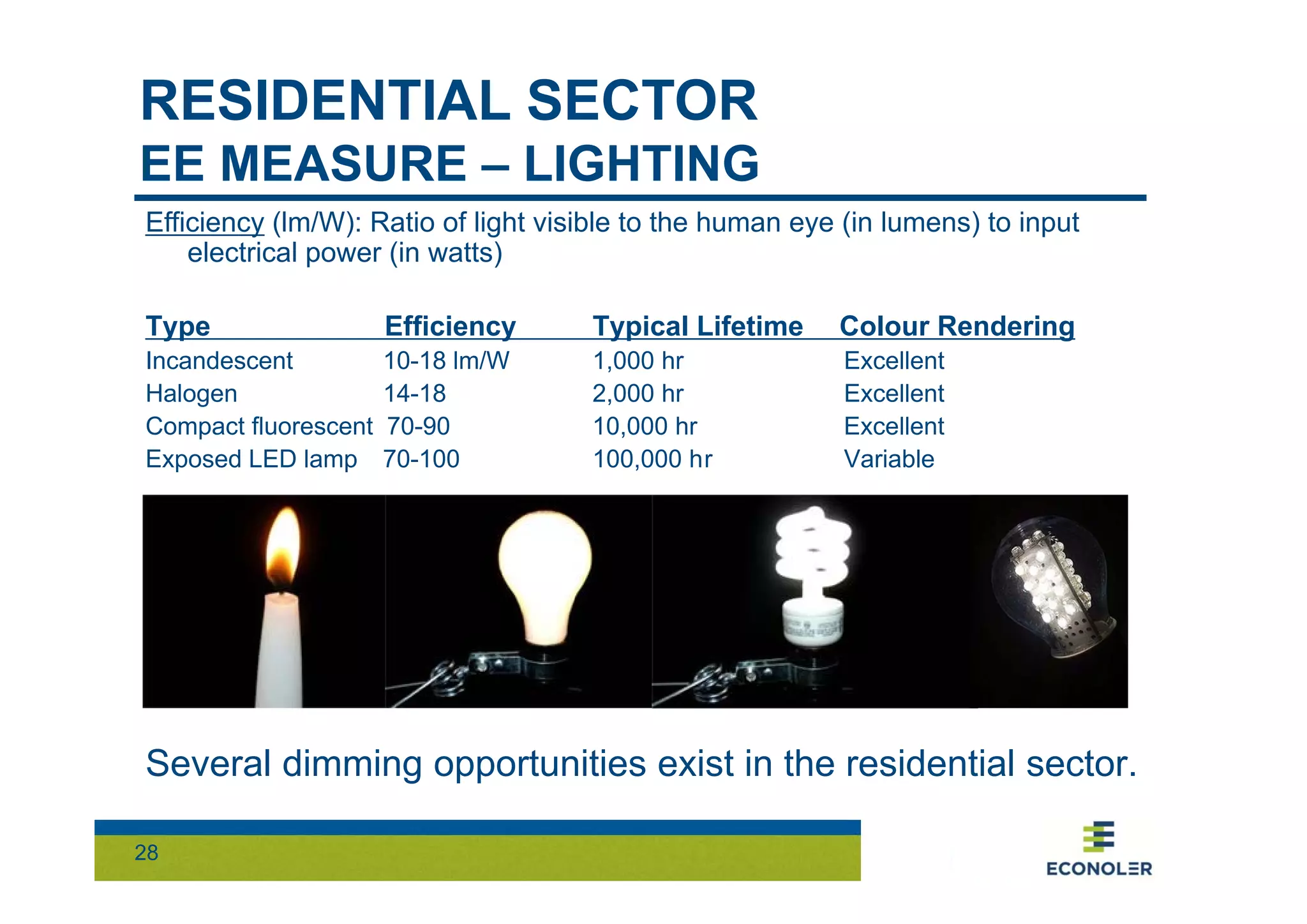

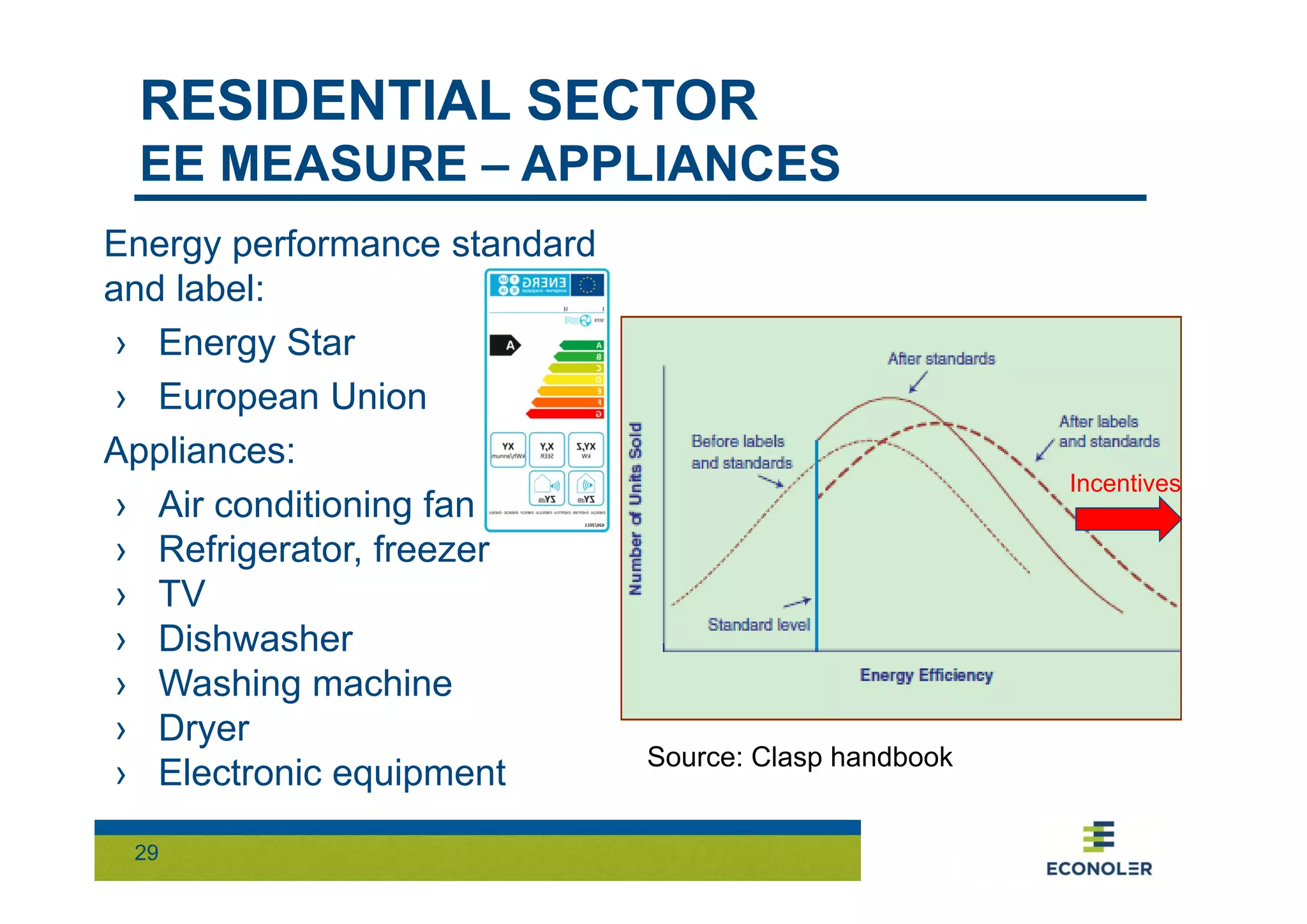

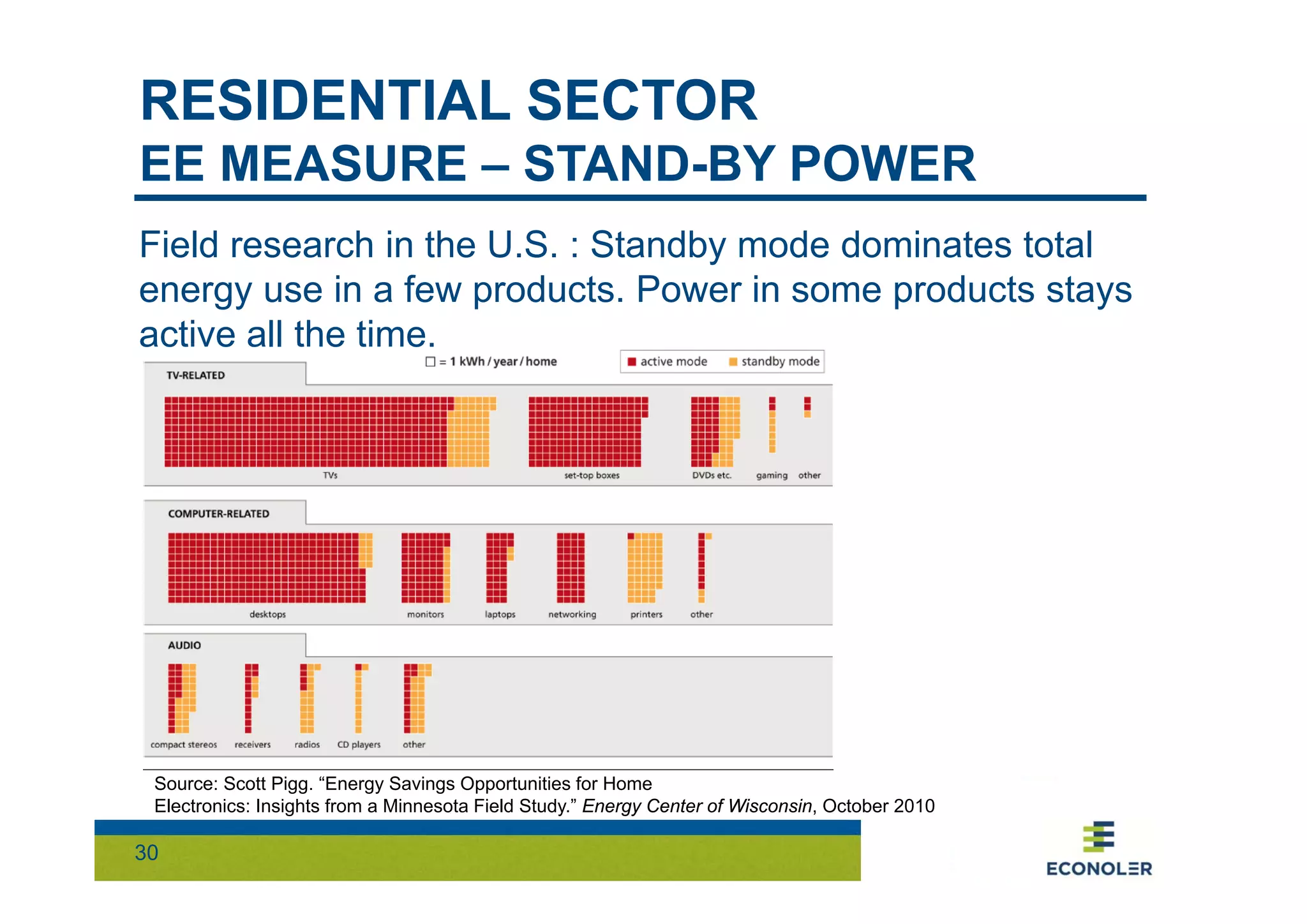

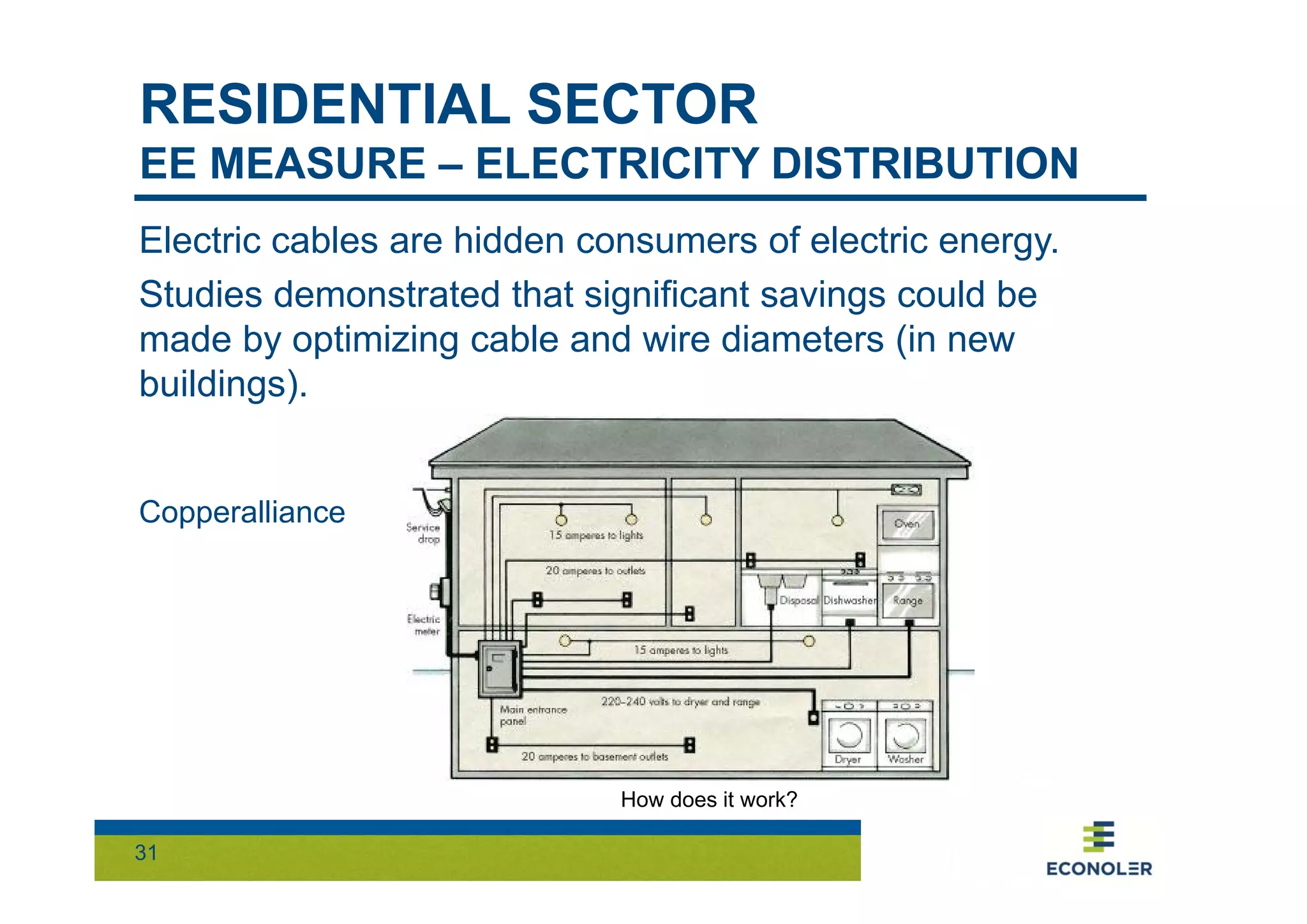

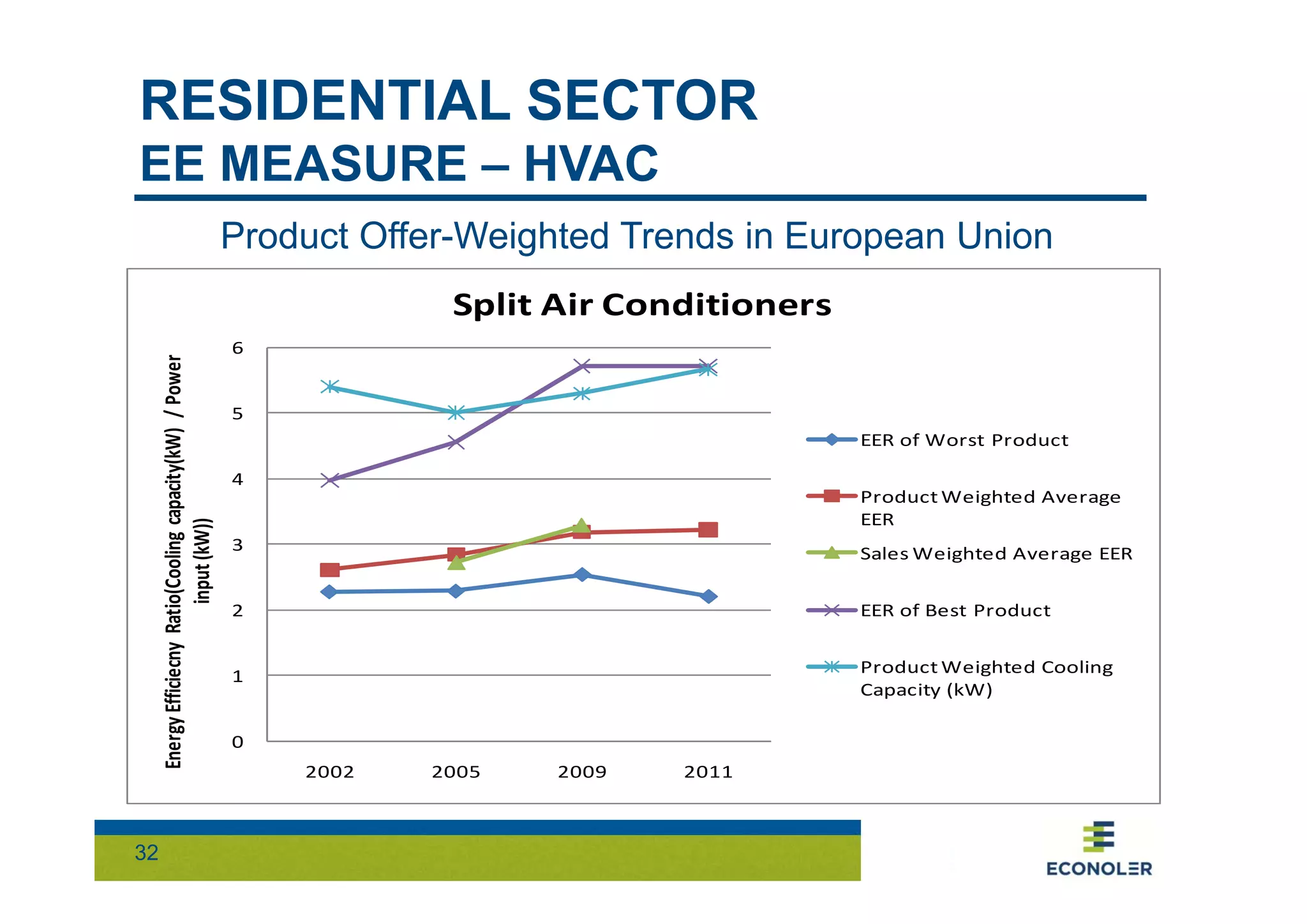

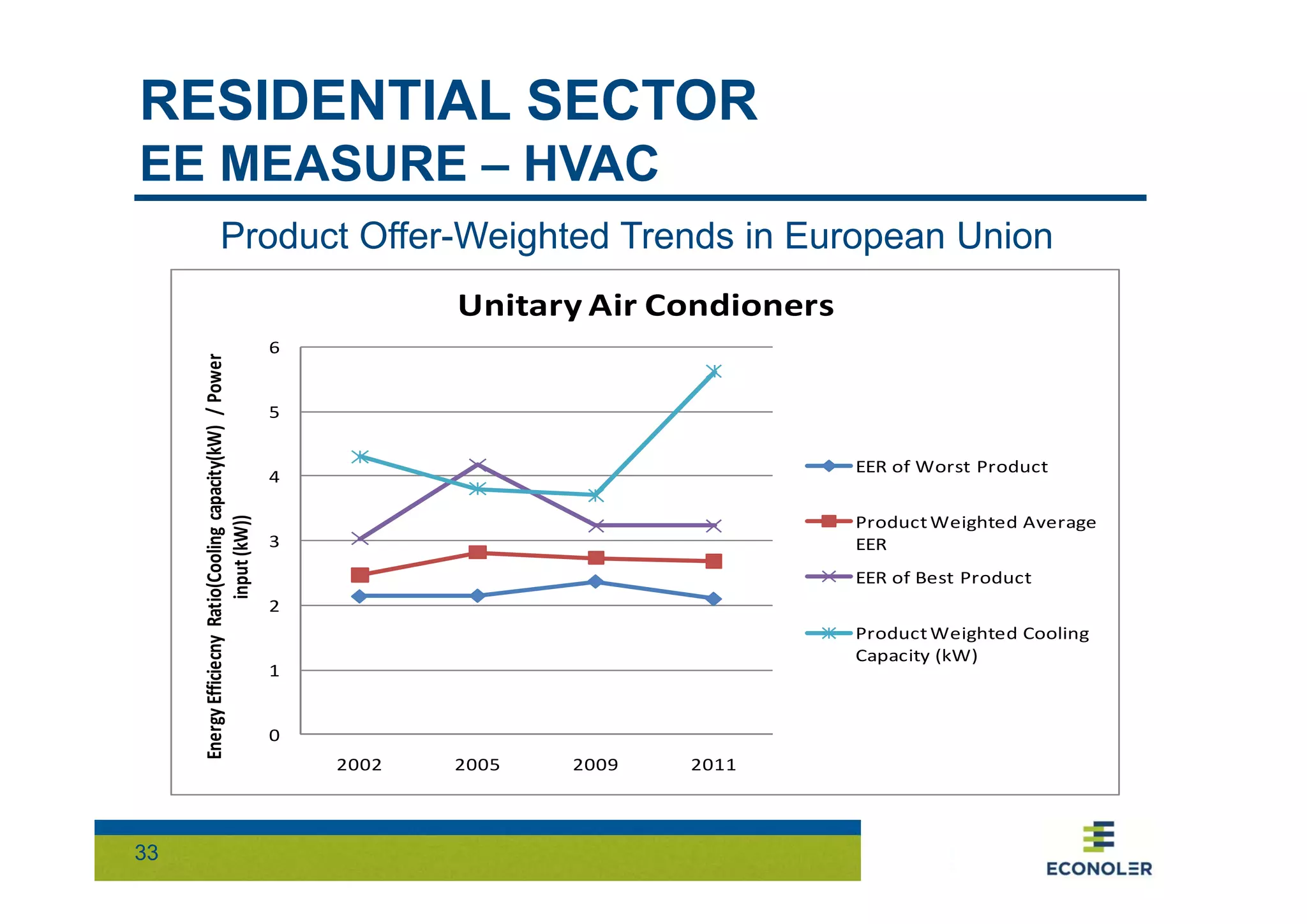

The document discusses common energy efficiency measures across various sectors including industrial, commercial, institutional, and residential. For the industrial sector, key measures discussed include improving motor and compressor system efficiency through upgrades like premium efficiency motors, variable speed drives, and leak detection/repair. Commercial measures center around HVAC, lighting, and building envelope upgrades. Residential focuses on insulation, windows, appliances, and reducing standby power consumption.