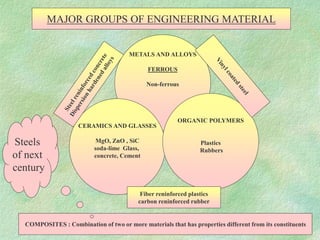

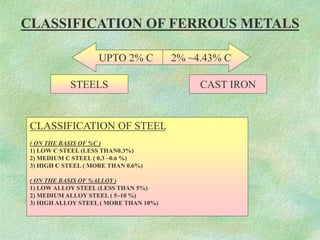

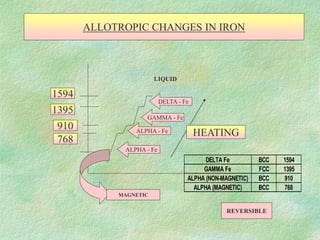

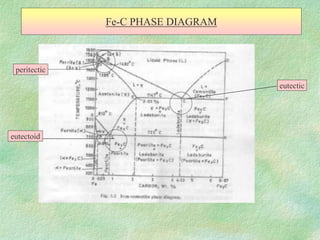

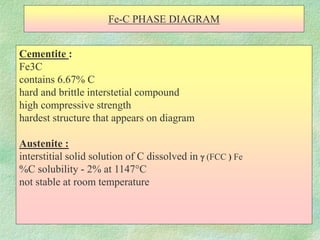

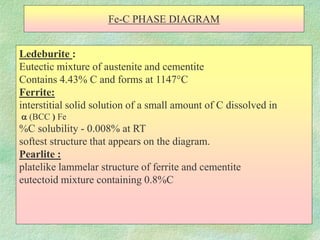

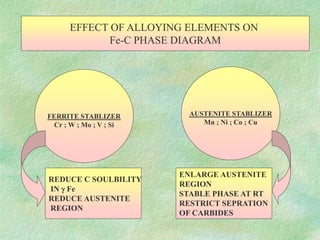

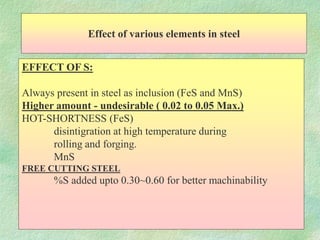

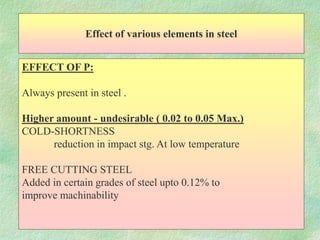

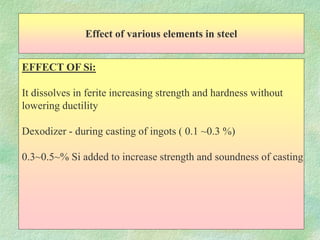

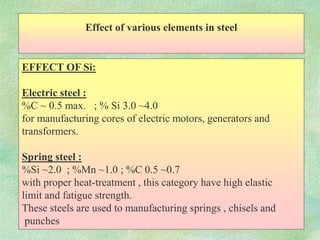

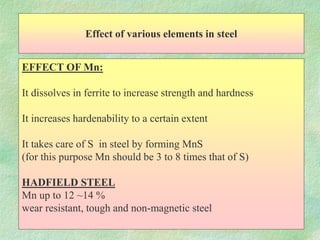

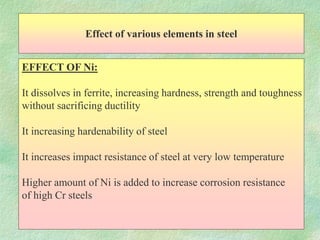

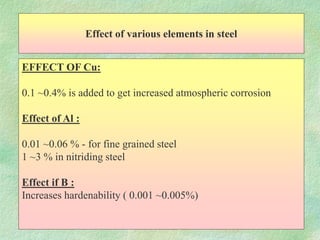

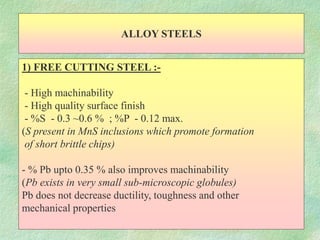

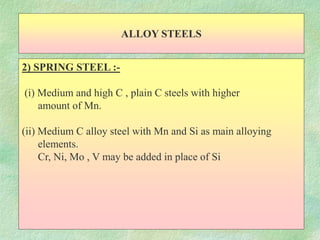

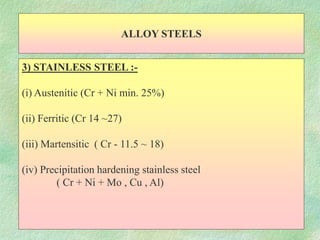

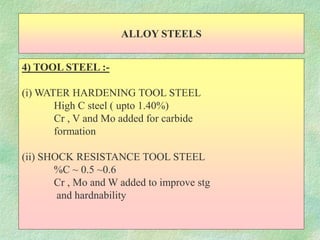

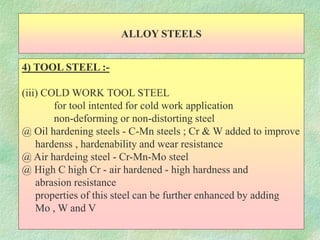

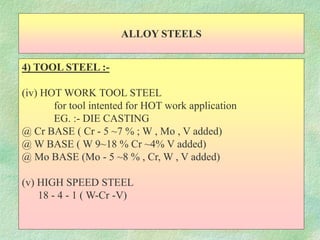

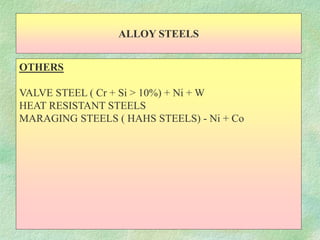

This document discusses the classification and properties of materials, with a focus on steels and the effect of alloying elements. It classifies materials as metals, ceramics, polymers and composites. It describes the major groups of engineering materials and classifies ferrous metals. The document discusses allotypic changes in iron, the Fe-C phase diagram, phases present, and the effect of alloying elements like C, Cr, Ni, Mo, Mn, Si, S, P, Cu and others on the diagram and properties of steel. It also summarizes various alloy steels like spring steel, stainless steel, tool steel, valve steel and heat resistant steels.