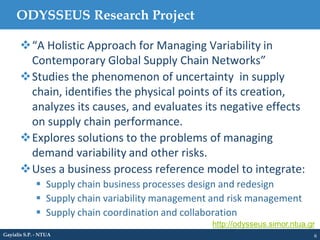

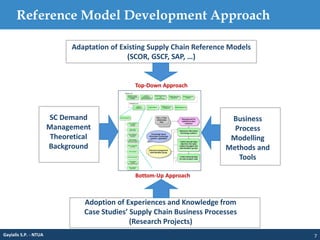

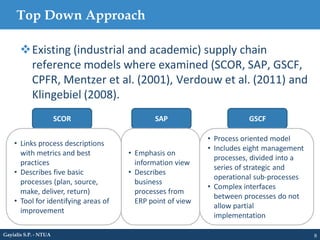

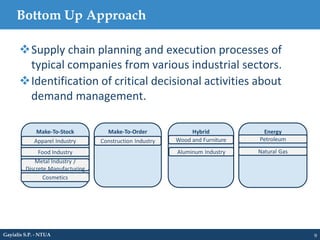

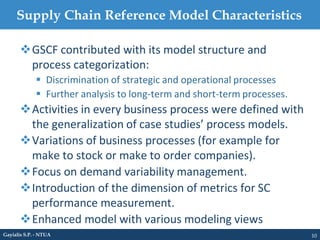

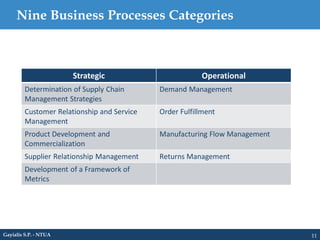

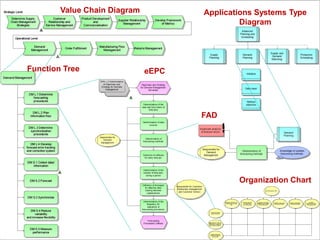

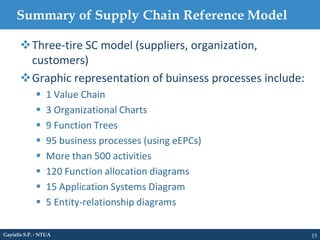

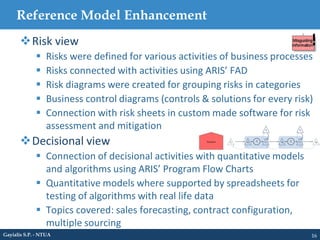

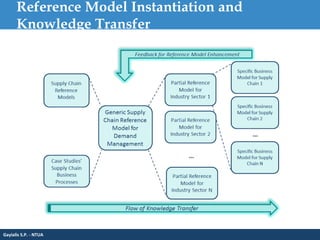

The document discusses a business process modeling approach to managing demand in contemporary supply chains, highlighting the complexities and costs associated with poorly managed demand and uncertainty. It emphasizes the need for reference models to improve demand management and presents the Odysseus research project, which aims to develop a holistic approach to managing variability in supply chain networks. The research includes the adaptation of existing models and the creation of a generic supply chain model focused on demand management, allowing for customization across different industry sectors.