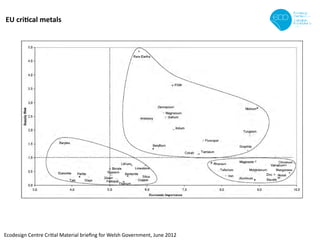

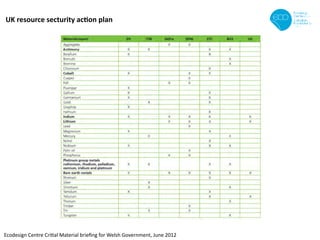

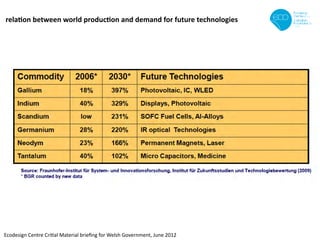

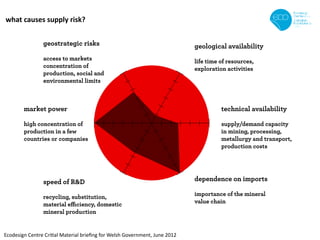

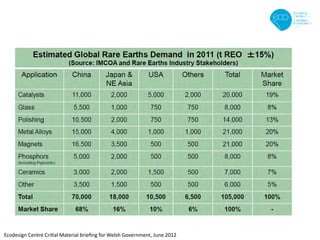

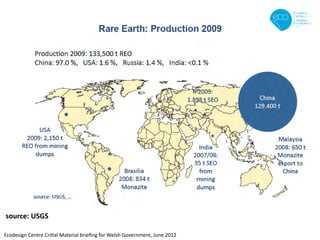

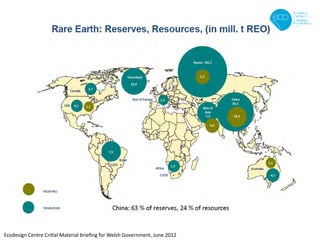

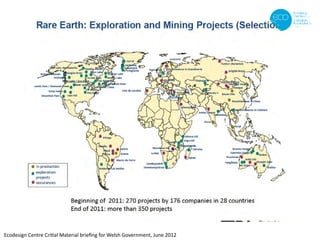

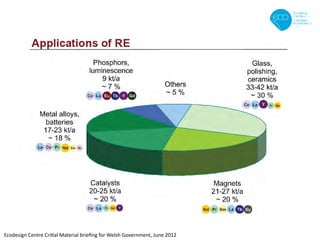

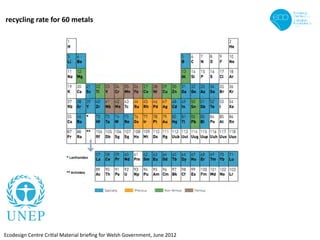

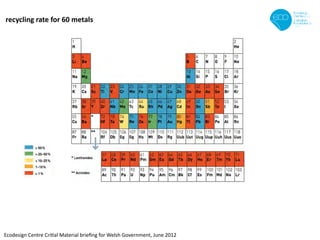

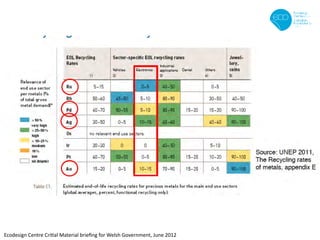

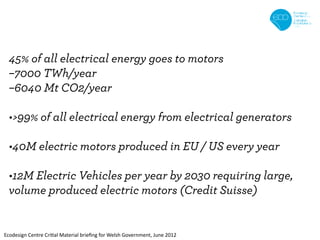

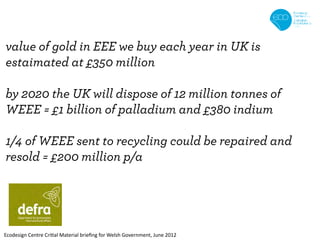

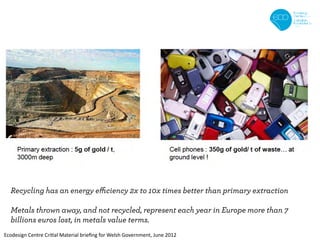

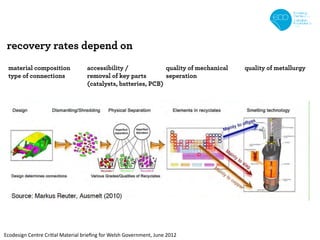

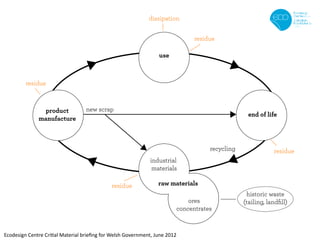

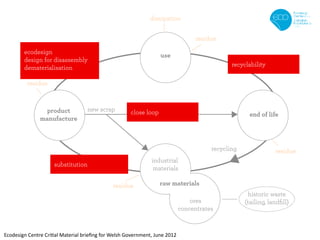

The document discusses key issues related to critical materials and opportunities for addressing supply risks. It notes that many critical metals are traded in small quantities and production is concentrated in a few countries, creating supply risks. Recycling rates are currently minimal due to factors like product design. However, opportunities exist in improving design for recyclability and resource efficiency, as well as increasing recycling which can be more energy efficient than primary extraction. Addressing critical material supply risks will require actions on both the supply and demand sides.