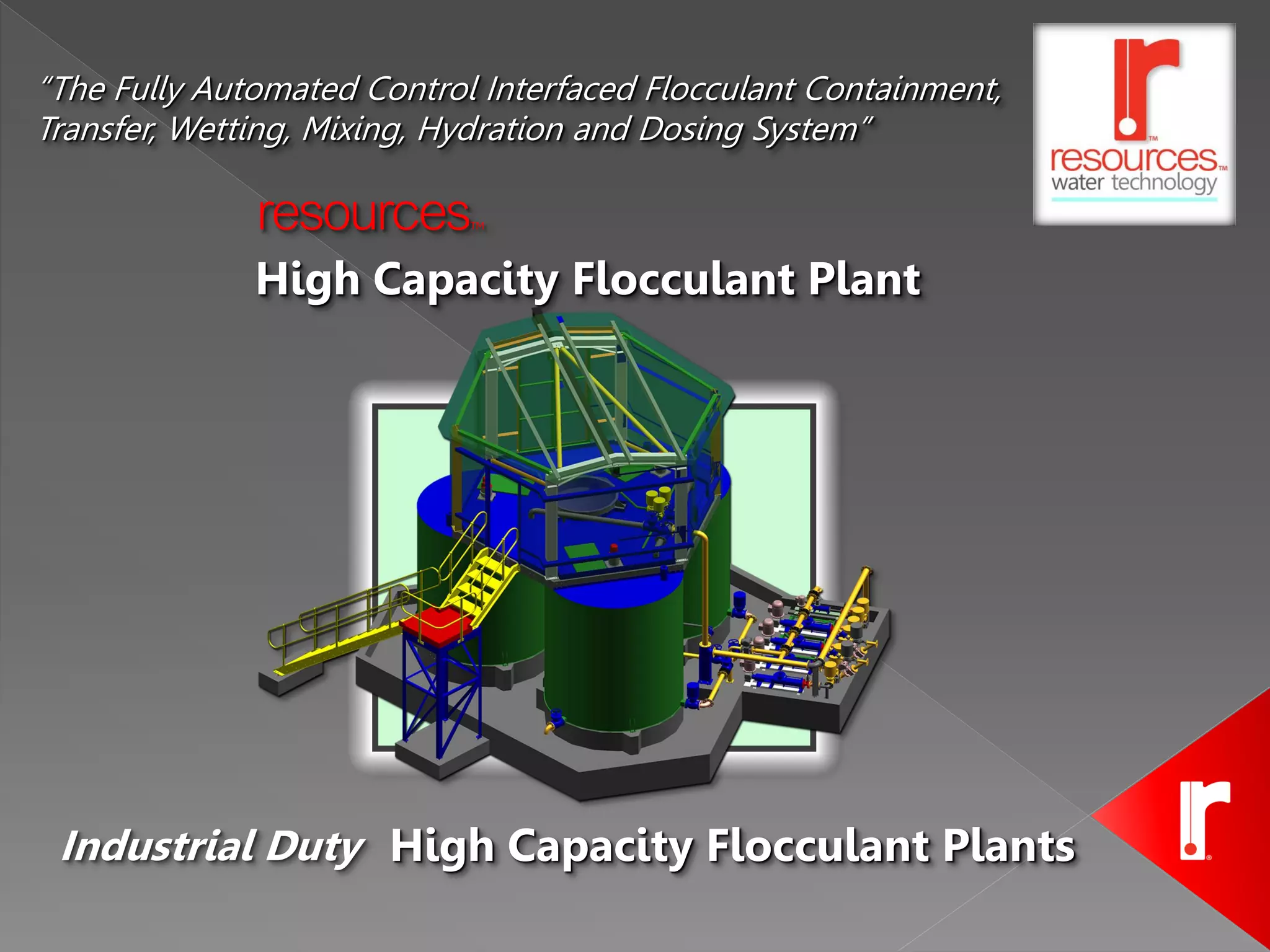

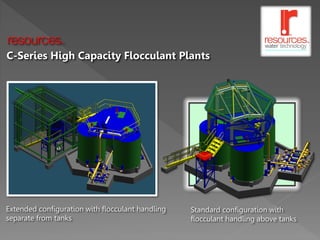

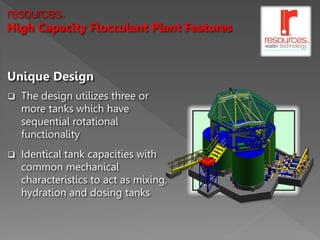

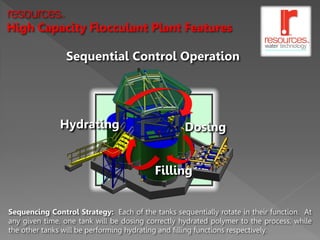

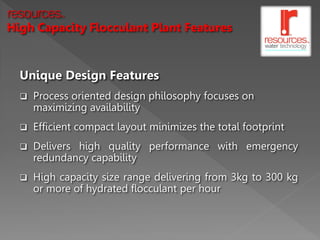

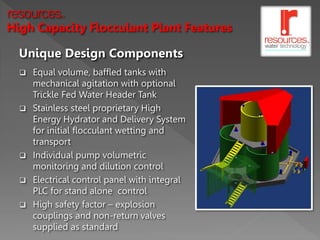

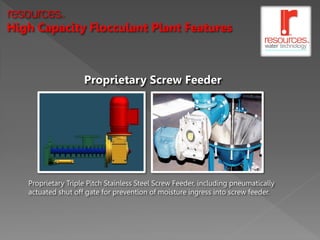

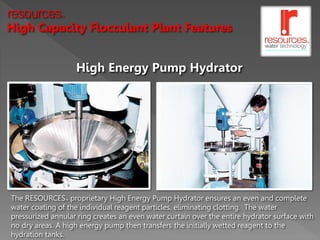

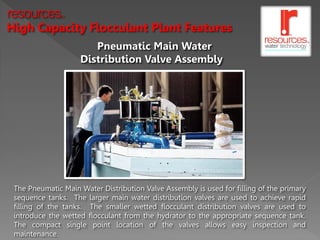

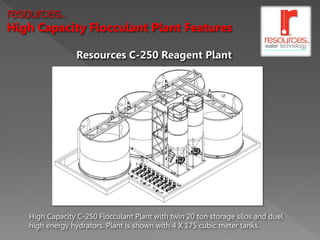

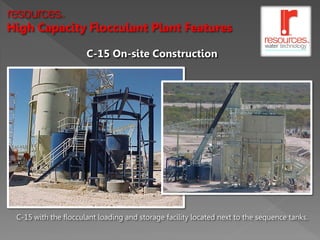

The document discusses high capacity flocculant plants for industrial use. It describes the sizing and selection process for the plants based on hourly flocculant requirements. It also covers flocculant concentration considerations and lists several models in the C-Series that can process between 3kg to 300kg of flocculant per hour. Key features of the plants include their unique sequential tank design, proprietary hydration and feeding systems, and safety components. The benefits outlined are high process availability, optimal thickener performance, minimal flocculant loss, and versatility.