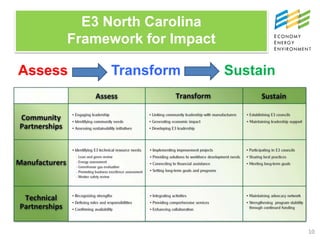

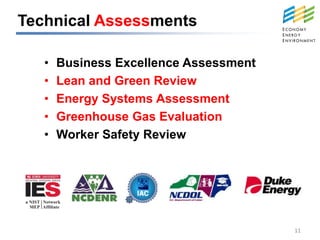

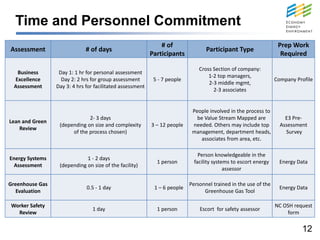

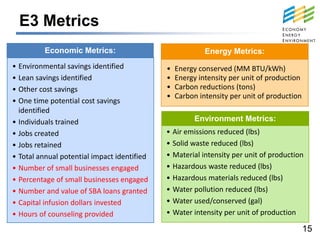

The E3 program works with manufacturers in North Carolina to help them increase sustainability and profitability. It partners with over 200 organizations across 18 communities. Through technical assessments, over 150 manufacturers have identified over $16 million in savings. The program provides assessments in areas like lean practices, energy use, and safety to help manufacturers transform operations. It also aims to create industry groups to promote long-term sharing of best practices.