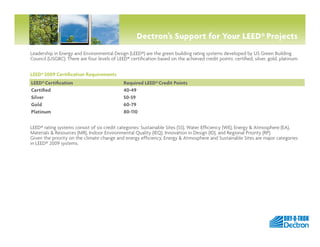

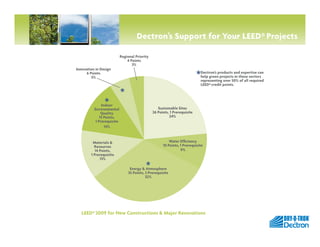

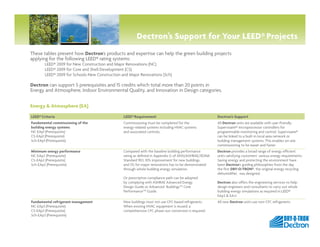

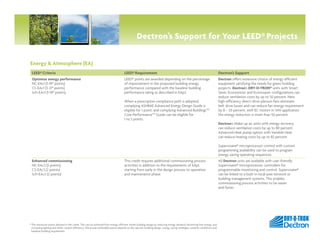

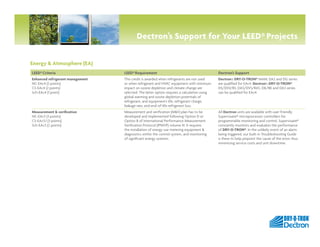

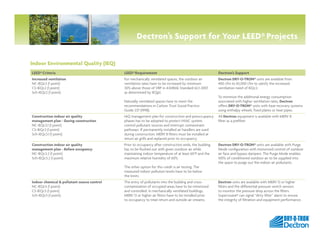

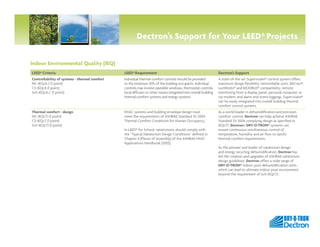

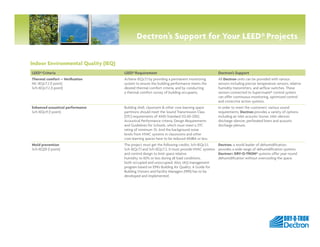

Dectron supports LEED® projects through various energy-efficient products and expertise, contributing significantly to achieving LEED® certification categories such as Energy & Atmosphere and Indoor Environmental Quality. The document outlines how Dectron's units meet LEED® 2009 criteria, detailing prerequisites and credit points available in different categories while emphasizing their commitment to sustainability and energy efficiency. Dectron's offerings include advanced controls and systems to optimize energy performance, ensure indoor air quality, and enhance overall building design efficiency.