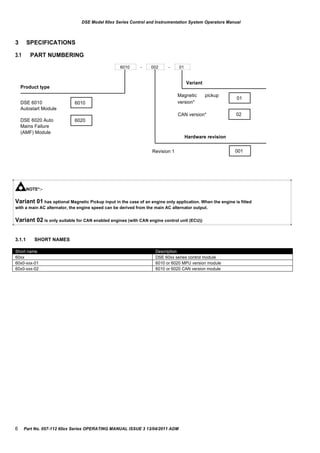

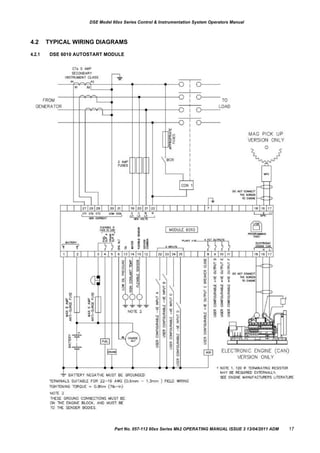

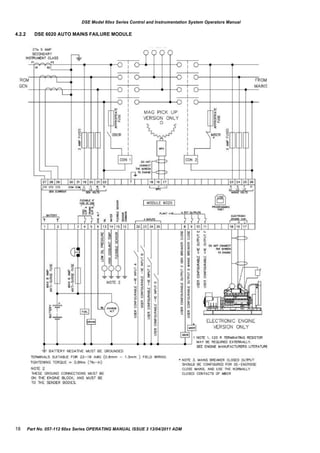

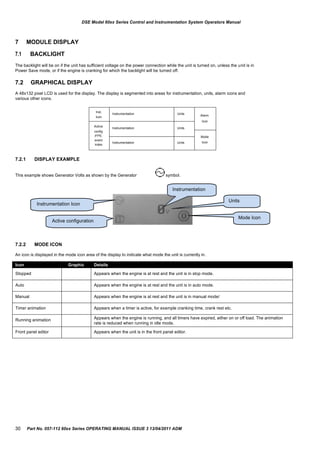

This document provides specifications and operating instructions for the DSE60xx series control module. It includes information on part numbering, power supply requirements, inputs, outputs, dimensions, applicable standards, installation, operation, the module display, front panel configuration, commissioning, fault finding, and maintenance. The DSE60xx is a generator control and instrumentation system that can automatically start and stop the engine/generator. It monitors operational parameters and indicates fault conditions on its LCD display.