Dr atif shahzad_engg_ management_lecture_inventory models

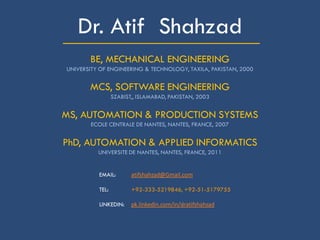

- 1. _____________________Dr. Atif Shahzad BE, MECHANICAL ENGINEERING UNIVERSITY OF ENGINEERING & TECHNOLOGY, TAXILA, PAKISTAN, 2000 MCS, SOFTWARE ENGINEERING SZABIST,, ISLAMABAD, PAKISTAN, 2003 MS, AUTOMATION & PRODUCTION SYSTEMS ECOLE CENTRALE DE NANTES, NANTES, FRANCE, 2007 PhD, AUTOMATION & APPLIED INFORMATICS UNIVERSITE DE NANTES, NANTES, FRANCE, 2011 EMAIL: atifshahzad@Gmail.com TEL: +92-333-5219846, +92-51-5179755 LINKEDIN: pk.linkedin.com/in/dratifshahzad

- 3. Dr.AtifShahzad Review Reasons for Keeping Inventories Inventory Management Inventory Control • what to order, • when to order, • how much to order and • how much to stock Techniques of Inventory Control • ABC analysis • HML analysis • VED analysis • FSN analysis • SDE analysis • GOLF analysis • SOS analysis

- 4. Dr.AtifShahzad 17–4 Deciding on the inventory model Assume an analyst applies an inventory model that does not allow for spoilage to a grocery chain’s ordering policy for lettuce and formulates the strategy of ordering lettuce in large amounts every 14 days. A little thought will show that this is obliviously foolish. This strategy implies that lettuce will be spoiled. However it is not a failure of inventory, it is a failure to apply the correct model.

- 5. Dr.AtifShahzad EOQ & Re-order point EOQ – gives answer to question “How much to Order” Re-order point – gives answer to question “when to order”

- 7. Dr.AtifShahzad 17–7 optimum inventory level Ordering cost • Quotation or tendering Requisitioning • Order placing • Transportation • Receiving, inspecting and storing • Quality control • Clerical and staff Stock-out cost Carrying costs

- 8. Dr.AtifShahzad 17–8 optimum inventory level Ordering cost Stock-out cost • Loss of sale • Failure to meet delivery commitments Carrying costs

- 9. Dr.AtifShahzad 17–9 optimum inventory level Ordering cost Stock-out cost Carrying costs • Warehousing or storage Handling • Clerical and staff Insurance • Interest Deterioration,shrinkage, • evaporation and obsolescence • Taxes • Cost of capital

- 10. Dr.AtifShahzad Walmart WALMART making sure that the shelves are stocked with tens of thousands of products is no simple matter for inventory managers at Walmart, which has ¤ 10,700 Walmart stores and Sam’s Club locations in 27 countries, ¤ employs more than 2.2 million associates, ¤ serves245 million customers per week worldwide, ¤ and uses 100,000 suppliers.

- 11. Dr.AtifShahzad 17–11 Approaches Certainty approach • Uncertain variables and risk are addressed separately Uncertainty approach • Uncertain variables and risk are addressedsimultaneously Deterministic approach Probabilistic approach

- 12. Dr.AtifShahzad 17–12 Basic EOQ Model: Assumptions Seasonal fluctuation in demand are ruled out Zero lead time – Time lapsed between purchase order and inventory usage Cost of placing an order and receiving are same and independent of the units ordered Annual cost of carrying the inventory is constant Total inventory cost = Ordering cost + carrying cost ECONOMICORDERQUANTITY

- 13. Dr.AtifShahzad EOQ – Three Approaches Trial and Error method Order-formula approach Graphical approach

- 14. Dr.AtifShahzad Trial and Error method Trial and Error method Order-formula approach Graphical approach Order size Q 1200 600 400 300 240 200 150 120 100 Average inventory Q/2 600 300 200 150 120 100 75 60 50 No. of orders C/Q 1 2 3 4 5 6 8 10 12 Annual carrying cost I* Q/2 600 300 200 150 120 100 75 60 50 Annual ordering cost O*C/Q 37.5 75 112.5 150 187.5 225 300 375 450 Total annual cost 637.5 375 312.5 300 307.5 325 375 435 500 Assumptions:- Annual requirement (C)=1200 units Carrying cost (I) = Rs.1 Ordering cost (O) =Rs.37.5

- 15. Dr.AtifShahzad Order-formula approach EOQ =(2*1200*37.5/1) = 300 units Trial and Error method Order-formula approach Graphical approach Assumptions:- Annual requirement (C)=1200 units Carrying cost (I) = Rs.1 Ordering cost (O) =Rs.37.5 EOQ =(2CO/I) C = Annual demand O = Ordering cost per order I = Carrying cost per unit

- 16. Dr.AtifShahzad Graphical approach Trial and Error method Order-formula approach Graphical approach Assumptions:- Annual requirement (C)=1200 units Carrying cost (I) = Rs.1 Ordering cost (O) =Rs.37.5 CostinRS. Order quantity EOQ0

- 17. Dr.AtifShahzad Graphical approach Trial and Error method Order-formula approach Graphical approach

- 18. Dr.AtifShahzad QUIZ A plant makes monthly shipments of electric drills to a wholesaler in average lot sizes of 280 drills. The wholesaler’s average demand is 70 drills a week, and the lead time from the plant is 3 weeks. The wholesaler must pay for the inventory from the moment the plant makes a shipment. If the wholesaler is willing to increase its purchase quantity to 350 units, the plant will give priority to the wholesaler and guarantee a lead time of only2 weeks. What is the effect on the wholesaler’s cycle and pipeline inventories? Intellectualssolveproblems; geniusesprevent them.

- 19. Dr.AtifShahzad QUIZ A museum of natural history opened a gift shop two years ago. Managing inventories has become a problem. Low inventory turnover is squeezing profit margins and causing cash-flow problems. One of the top-selling SKUs in the container group at the museum’s gift shop is a bird feeder. Sales are 18 units per week, and the supplier charges $60 per unit. The cost of placing an order with the supplier is $45. Annual holding cost is 25 percent of a feeder’s value, and the museum operates 52 weeks per year. Management chose a 390-unit lot size so that new orders could be placed less frequently. What is the annual cycle-inventory cost of the current policy of using a 390-unit lot size? Would a lot size of 468 be better?

- 20. Dr.AtifShahzad QUIZ What is the annual cycle-inventory cost of the current policy of using a 390-unit lot size? Would a lot size of 468 be better?

- 21. Dr.AtifShahzad QUIZ What is the annual cycle-inventory cost of the current policy of using a 390-unit lot size? Would a lot size of 468 be better?

- 22. Dr.AtifShahzad EOQ We use calculus to obtain the EOQ formula from the total annual cycle- inventory cost function. We take the first derivative of the total annual cycle-inventory cost function with respect to Q, set it equal to 0, and solve for Q.

- 24. Dr.AtifShahzad Activity A distribution center experiences an average weekly demand of 50 units for one of its items. The product is valued at $650 per unit. Inbound shipments from the factory warehouse average 350 units. Average lead time (including ordering delays and transit time) is 2 weeks. The distribution center operates 52 weeks per year; it carries a 1-week supply of inventory as safety stock and no anticipation inventory. What is the value of the average aggregate inventory being held by the distribution center?

- 25. Dr.AtifShahzad Activity A distribution center experiences an average weekly demand of 50 units for one of its items. The product is valued at $650 per unit. Inbound shipments from the factory warehouse average 350 units. Average lead time (including ordering delays and transit time) is 2 weeks. The distribution center operates 52 weeks per year; it carries a 1-week supply of inventory as safety stock and no anticipation inventory. What is the value of the average aggregate inventory being held by the distribution center?

- 26. Dr.AtifShahzad Certainty case of the inventory cycle T1,T2,T3,T4 represents the replenishment points Q 0 T1 T2 T3 T4 Average inventory = Q/2 Inventorylevel orderquantity

- 27. Dr.AtifShahzad Extension of basic EOQ model quantity discounts 27 T hewholeofscienceisnothingmore thana refinementofeverydaythinking. –Albert Einstein

- 28. Dr.AtifShahzad Extension of basic EOQ model Non-zero lead time If the lead time is‘n’ then procurement must be done prior to‘n’ days, i.e.T-n T1 - n T1 T2 - n T2 T3 - n T3 T4 - n T4 Q 0 Reorder point Time Placement of a order

- 29. Dr.AtifShahzad Extension of basic EOQ model Quantity discounts Quantity discounts are price incentives to purchase large quantities For example, a supplier may offer a price of $4.00 per unit for orders between 1 and 99 units, a price of $3.50 per unit for orders between 100 and 199 units, and a price of $3.00 per unit for orders of 200 or more units. The item’s price is no longer fixed, as assumed in the EOQ derivation; instead, if the order quantity is increased enough, the price is discounted. For any per-unit price level, P, the total cost is

- 30. Dr.AtifShahzad Extension of basic EOQ model Non- instantaneous Replenishment If an item is being produced internally rather than purchased, finished units may be used or sold as soon as they are completed, without waiting until a full lot is completed. For example, a restaurant that bakes its own dinner rolls begins to use some of the rolls from the first pan even before the baker finishes a five-pan batch. The inventory of rolls never reaches the full five-pan level, the way it would if the rolls all arrived at once on a truck sent by a supplier.

- 31. Dr.AtifShahzad Extension of basic EOQ model Figure depicts the usual case, in which the production rate, p, exceeds the demand rate, d. If demand and production were equal, manufacturing would be continuous with no buildup of cycle inventory. If the production rate is lower than the demand rate, sales opportunities are being missed on an ongoing basis.We assume that p > d here. Economic production lot size (ELS) Non- instantaneous Replenishment

- 32. Dr.AtifShahzad Some terminology cycle inventory: The portion of total inventory that varies directly with lot size. lot sizing: The determination of how frequently and in what quantity to order inventory. safety stock inventory: Surplus inventory that a company holds to protect against uncertainties in demand, lead time, and supply changes anticipation inventory: Inventory used to absorb uneven rates of demand or supply. Pipeline Inventory: Inventory that is created when an order for an item is issued but not yet received is called

- 33. Dr.AtifShahzad 17–33 Objectives of Inventory Control To ensure adequate supply of products to customer and avoid shortages as far as possible. To make sure that the financial investment in inventories is minimum (i.e., to see that the working capital is blocked to the minimum possible extent). Efficient purchasing, storing, consumption and accounting for materials is an important objective. To maintain timely record of inventories of all the items and to maintain the stock within the desired limits. To ensure timely action for replenishment. To provide a reserve stock for variations in lead times of delivery of materials. To provide a scientific base for both short-term and long-term planning of materials.

- 34. Dr.AtifShahzad 17–34 Benefits of Inventory Control Improvement in customer’s relationship because of the timely delivery of goods and service. Smooth and uninterrupted production and, hence, no stock out. Efficient utilisation of working capital. Helps in minimising loss due to deterioration, obsolescence damage and pilferage. Economy in purchasing. Eliminates the possibility of duplicate ordering.

- 35. QUESTIONS

- 36. THANK YOU FOR YOUR INTEREST