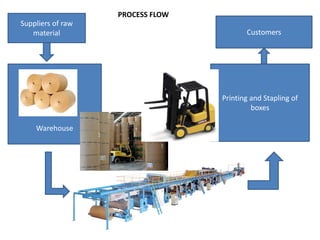

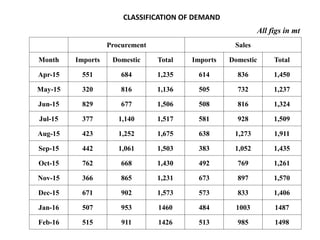

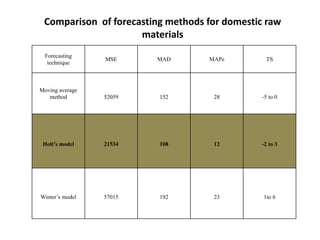

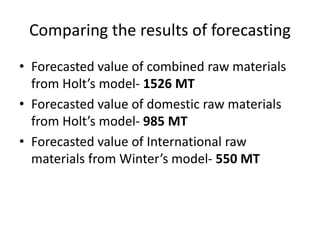

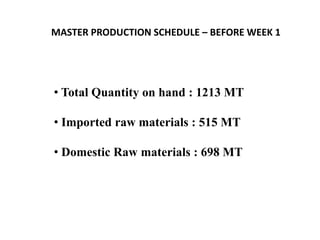

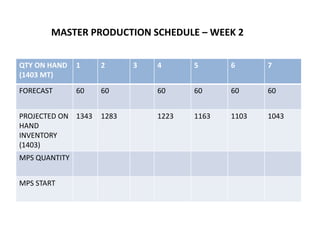

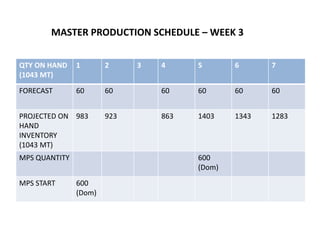

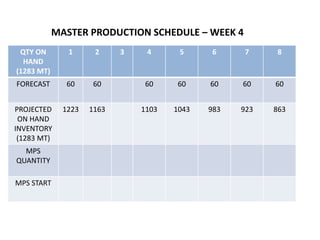

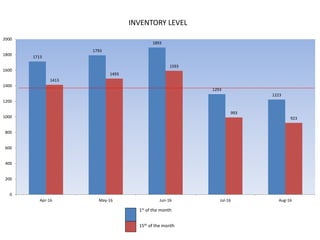

The document discusses effective inventory planning and control strategies for a corrugated box manufacturing plant. It provides an overview of the company profile and facilities. It then defines the current problems with raw material procurement and storage capacity. The objectives are to forecast demand, revise the replenishment policy and create a new master production schedule. The methodology involves data collection, forecasting analysis using Holt's, seasonal and moving average models, and comparing the existing versus proposed replenishment policies and schedules. The results show implementing a revised policy with domestic materials procured twice monthly improves inventory management.

![References

[1] Ajit Surajmal Kanodia, “Material Requirement Planning”, case study , May 1976.

[2] Matthew J Liberatore, “Using MRP and EOQ/safety stock for raw materials inventory control”, vol 9, no 2, February 1979.

[3] Gerhard Plenert, “Focusing material requirements planning (MRP) towards Performance”, Int.conf. Vol 119 , September1998.

[4] “U.S. Small Business Administration”, Inventory Control, 2000

[5] Dr Vassilis Moustakis, “Material requirement planning”, Vol 2 , January 2000.

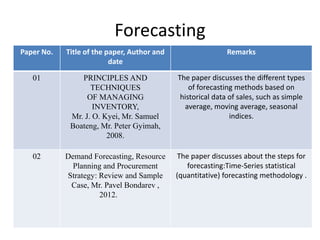

[6] Marcel Baumgartner, “Use of Statistical Forecasting Methods to Improve Demand Planning”, 2004.

[7] Catherine D. Black “Optimal Inventory Control in Cardboard Box Producing Factories”, 2004.”

[8] Chantana Thongma , Ungul Laptaned, “Improving efficiency of material requirement planning and safety stock”, Research paper, 2nd Int.

conf. May 18-20, 2007.

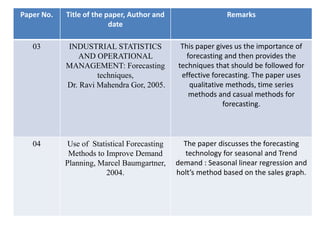

[9] Dr. Ravi Mahendra Gor, “Forecasting Techniques”, 2008.

[10] Mr. J. O. Kyei, Mr. Samuel Boateng, Mr. Peter Gyimah, “Principles And Techniques Of Managing Inventory”, 2008.

[11] Sevenpri Candra and Haryadi Sarjono, “Forecasting For Inventory Control”, School of Business Management, Bina Nusantara University,

Jakarta, 2008.

[12] Ralph D. Snyder, J. Keith Ord, Adrian Beaumont, “Forecasting the Intermittent Demand for Slow-Moving Items”, 2010.

[13] Professor Guillermo Gallego, “Production Management”, Vol 11, 2010.

[14] “Demand Forecasting, Resource planning and procurement stratigies”, Pavel Bondarev, 2012.

[15] Sunil Chopra, Peter Meindl, D. V. Kalra, “Supply Chain Management”, Fifth edition, 2013.](https://image.slidesharecdn.com/6791f91b-95b8-423e-93bb-1c872bb10559-160918103426/85/Presentation-40-320.jpg)