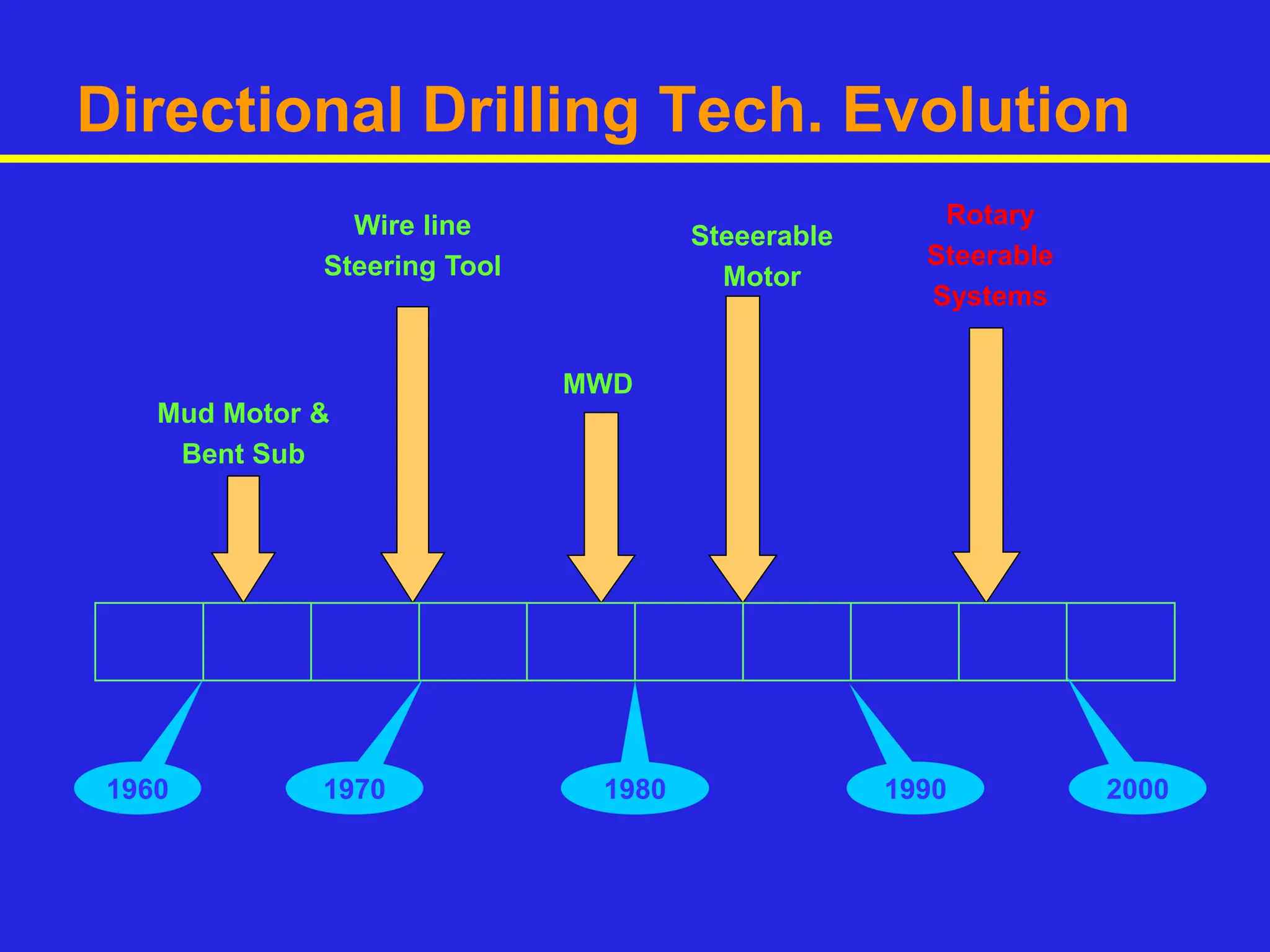

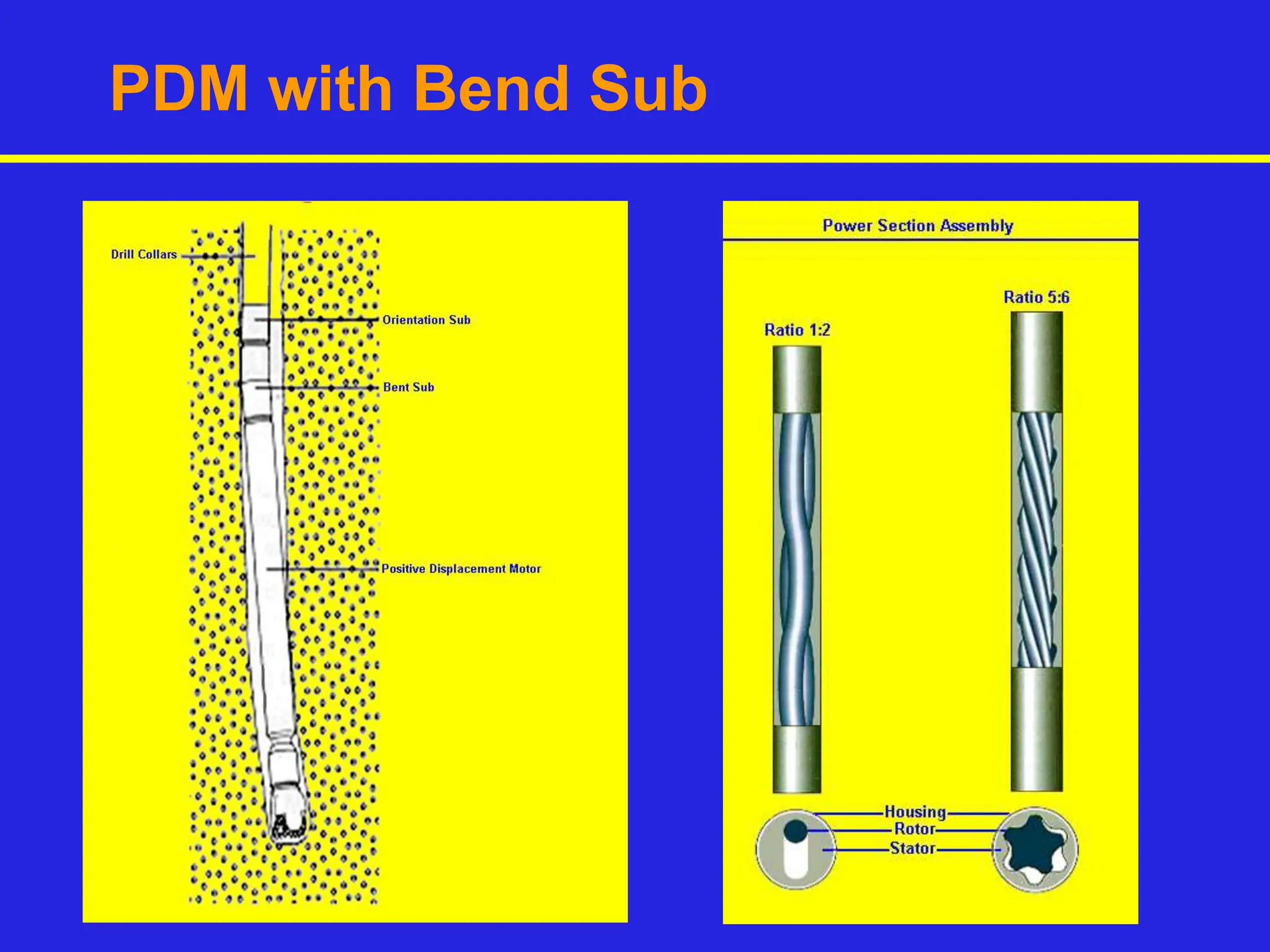

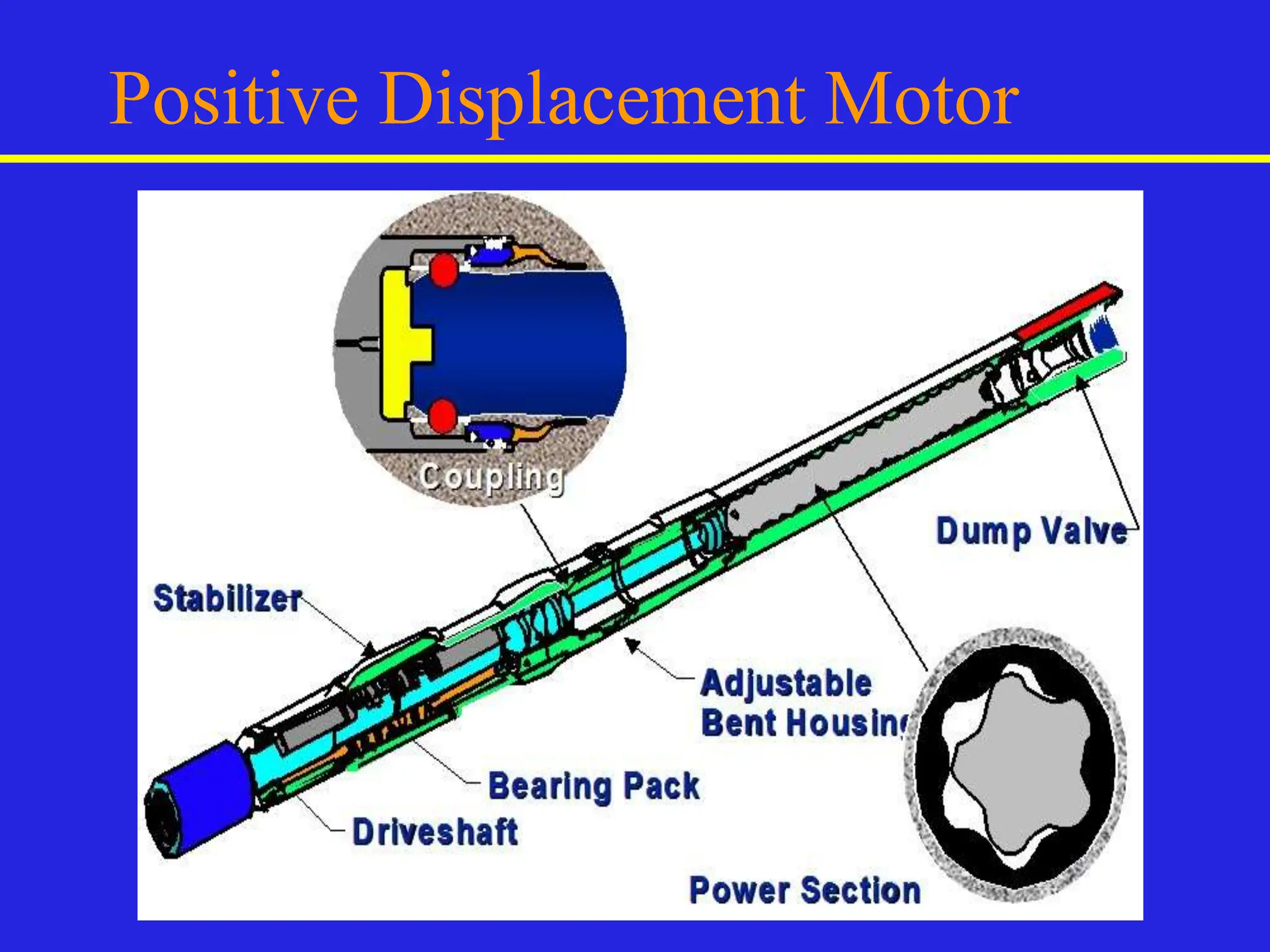

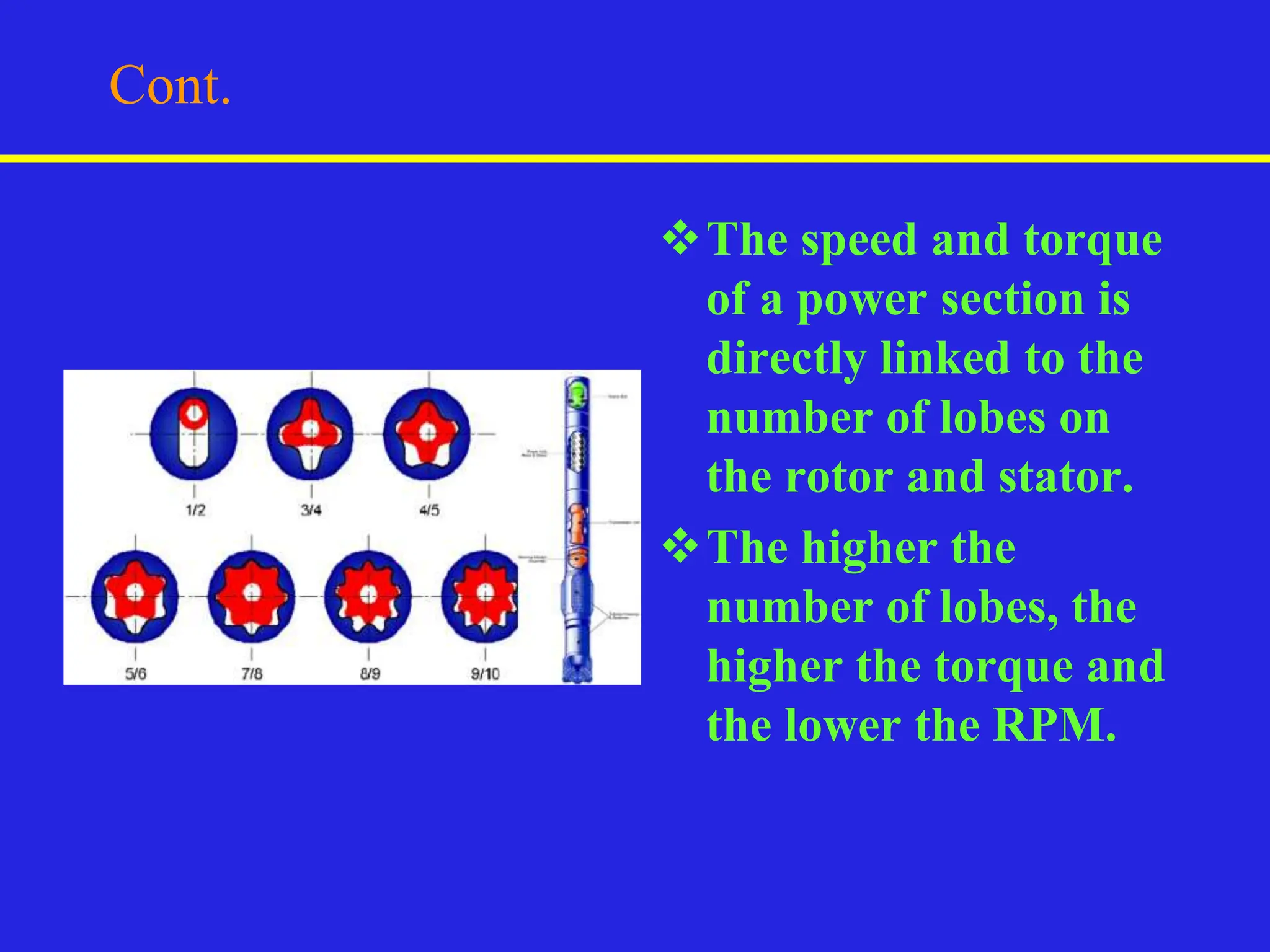

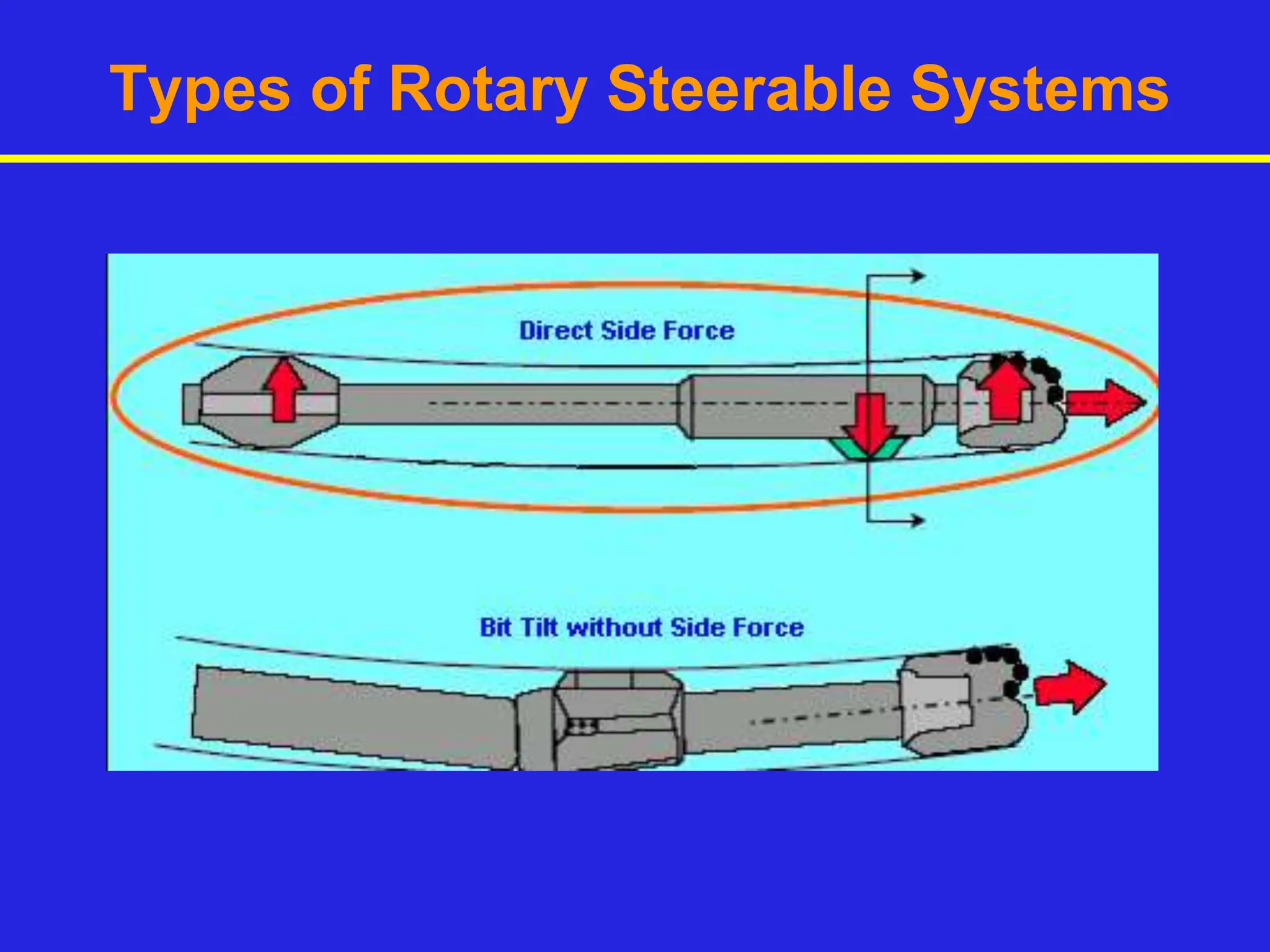

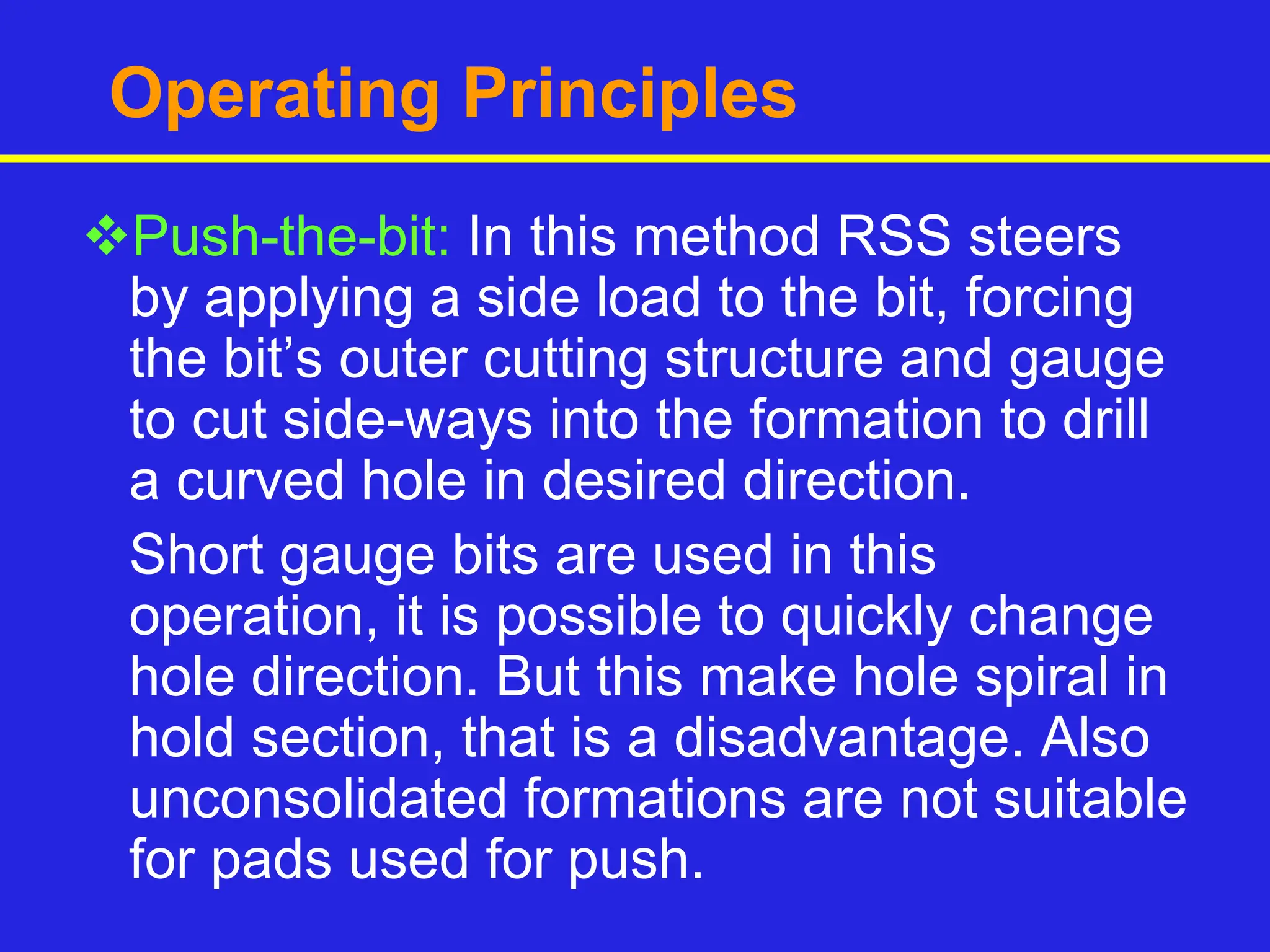

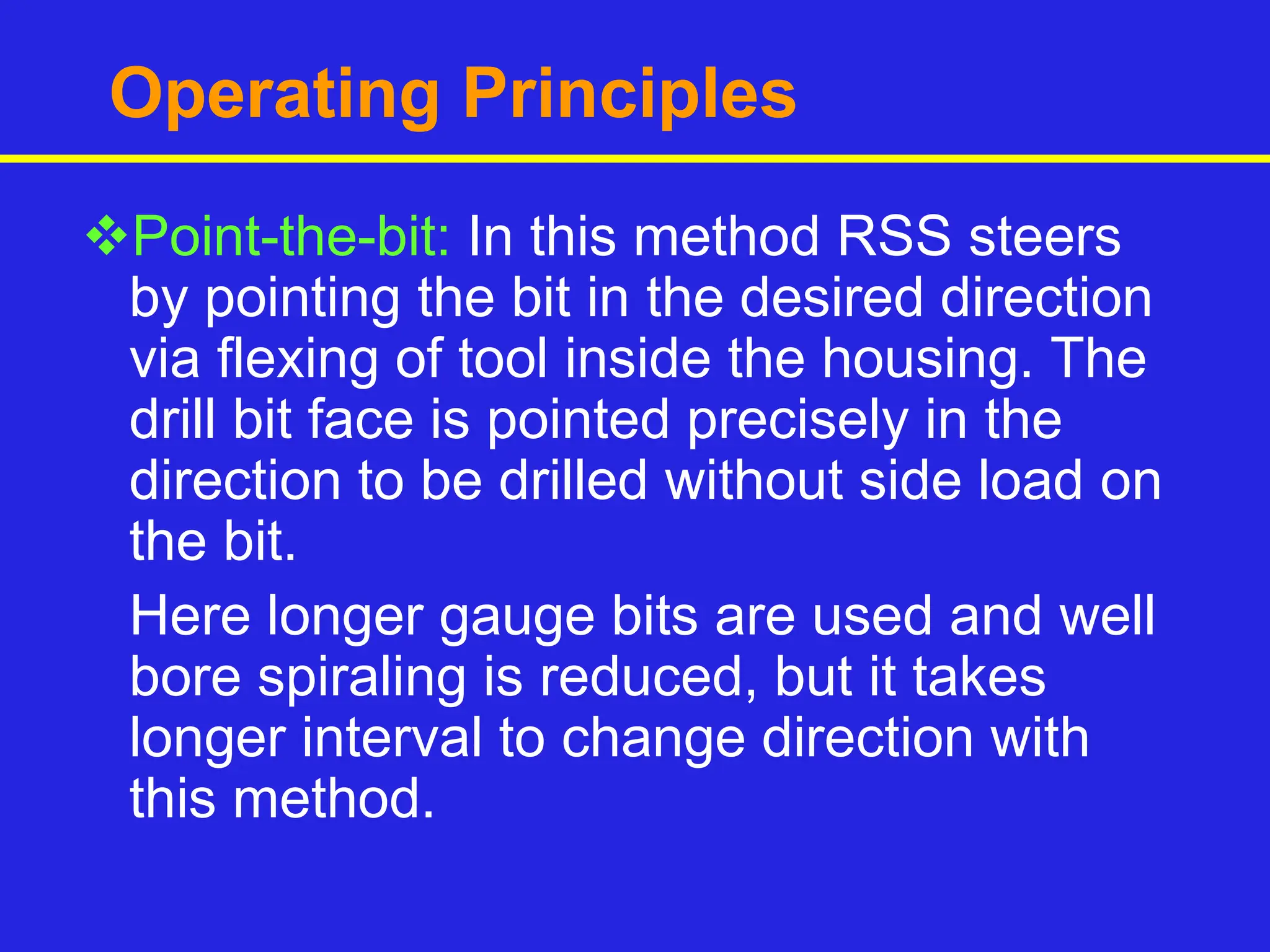

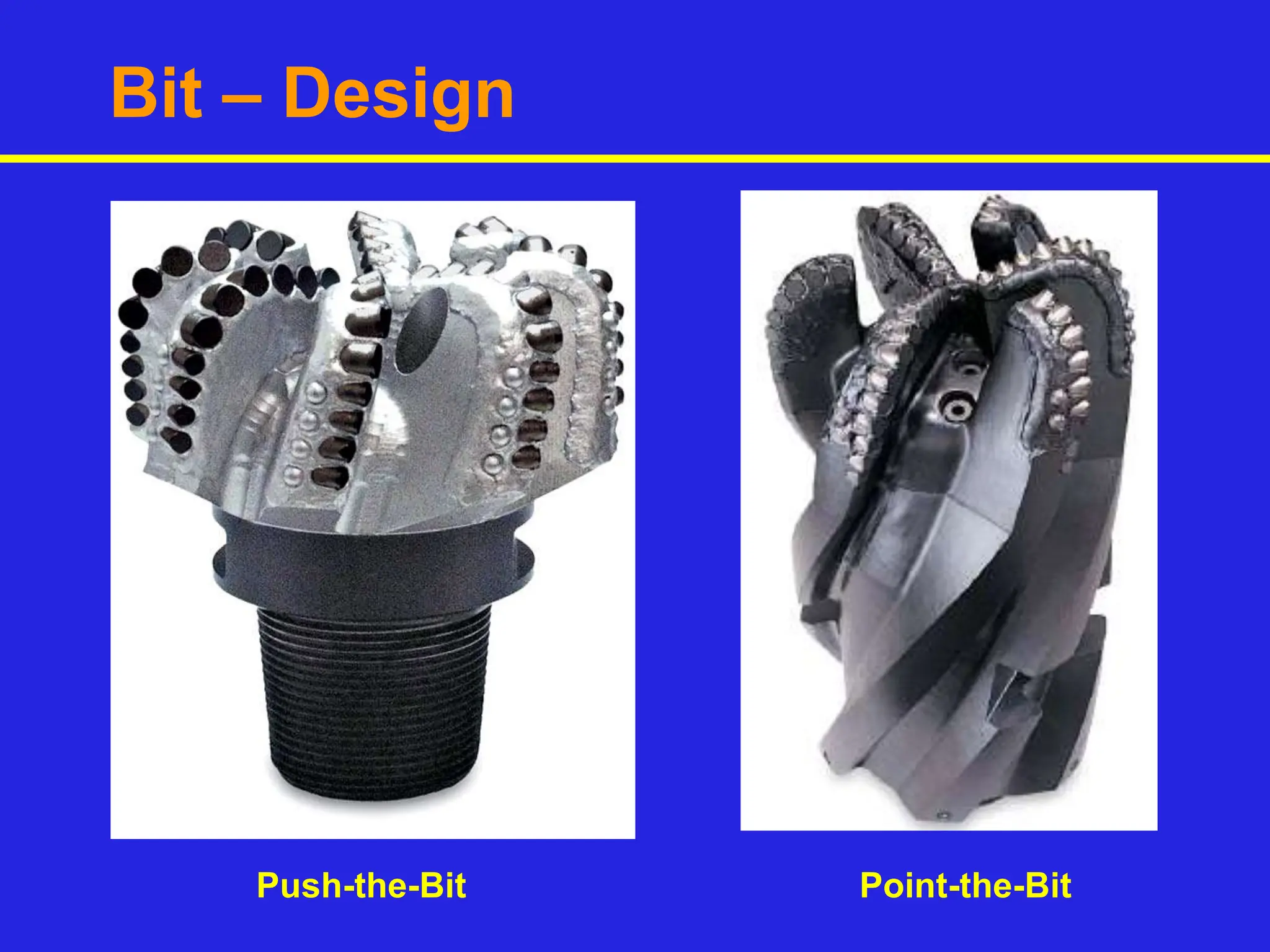

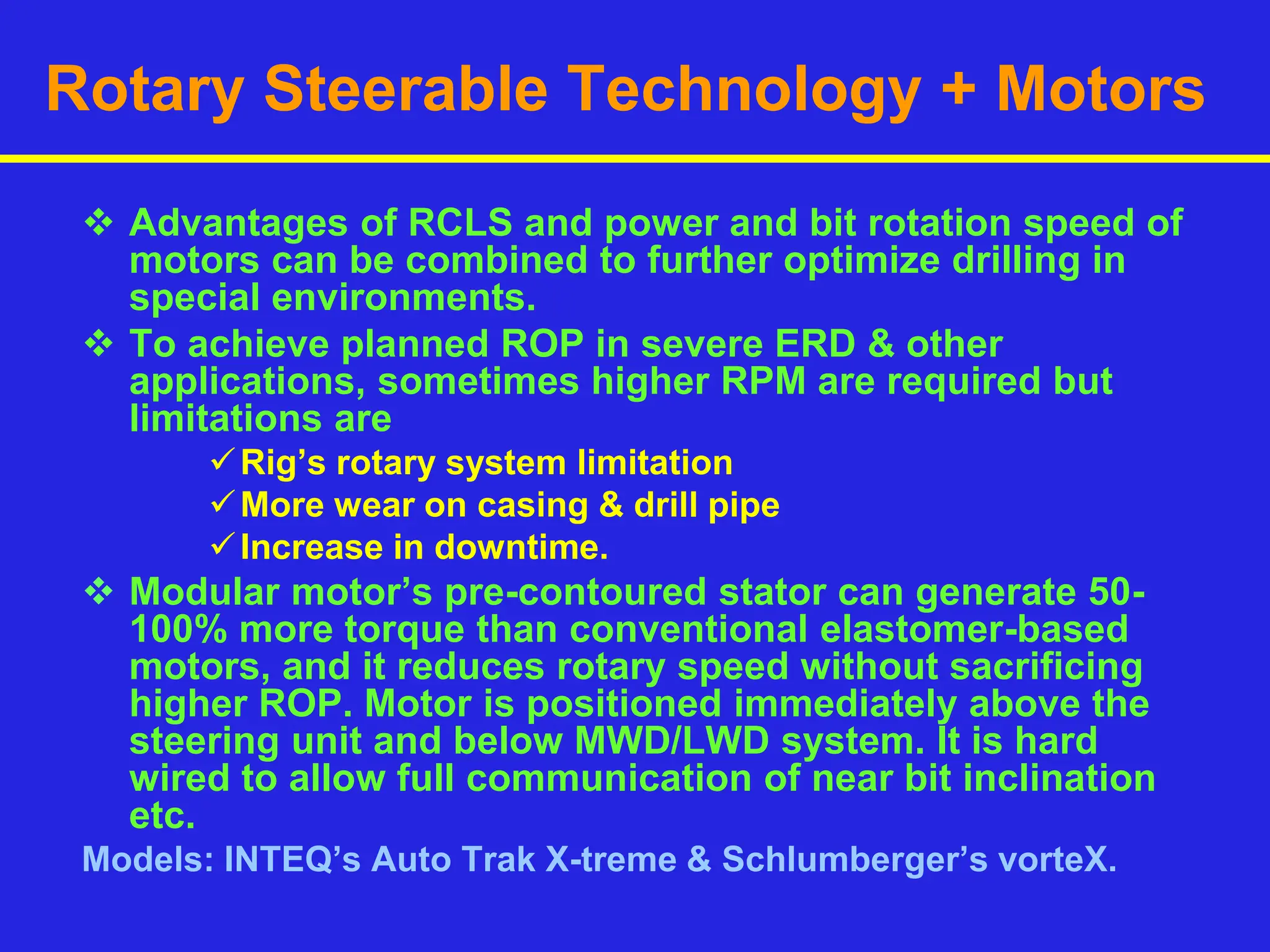

This document discusses the evolution of directional drilling technology from 1960 to present. It covers early technologies like mud motors and bent subs used for steering in the 1960s-1980s. Later developments included the introduction of wireline steering tools, MWD systems, and steerable motors. Rotary steerable systems were developed in the 1990s-2000s to allow simultaneous control of wellbore azimuth and inclination without needing to switch between rotating and sliding modes. The document describes different types of rotary steerable systems and how they work using either push-the-bit or point-the-bit operating principles.

![How does RSS Work [Point the bit]

In this system bit direction is controlled by deflection of

the bit drive shaft rather than relying on bit side forces

to steer the well while rotating the drill string.

In a compact bais unit- a pair of eccentric rings, one

nested inside the other, deviate a drive shaft mounted

on bearings at each end and enclosed in a non-rotating

outer sleeve.

Control system is self correcting guidance system,

uses near bit inclination signals and accordingly self

correcting electronics automatically maintain

directional tool face and inclination.

An anti-rotation device prevents slippage of the outer

housing while the tool is in the deflected, steering

mode, allowing for a stable tool face orientation.](https://image.slidesharecdn.com/ddrssmodified1-240327211603-2a4ed64c/75/Directional-drilling_Rotary-steering-system-ppt-21-2048.jpg)

![How does RSS Work [Point the bit]

Shaft deflection is achieved by a pair of eccentric

rings that can be rotated to any desired tool face

setting and varying degree of offset from the center.

For maximum operating life and reliability, the

system's bearings, seals, and other internal moving

components are all immersed in lubricating oil. And,

because the tool operates independently of well

bore fluids, there are virtually no mud compatibility

problems.

A pressure compensator maintains a slight positive

internal pressure across rotary seals.

Example: Geo-Pilot ® Rotary Steerable system](https://image.slidesharecdn.com/ddrssmodified1-240327211603-2a4ed64c/75/Directional-drilling_Rotary-steering-system-ppt-22-2048.jpg)

![How does RSS Work [Point the bit]](https://image.slidesharecdn.com/ddrssmodified1-240327211603-2a4ed64c/75/Directional-drilling_Rotary-steering-system-ppt-23-2048.jpg)

![How does RSS Work [Push the bit]

Pad Retracted Pad Extended](https://image.slidesharecdn.com/ddrssmodified1-240327211603-2a4ed64c/75/Directional-drilling_Rotary-steering-system-ppt-26-2048.jpg)