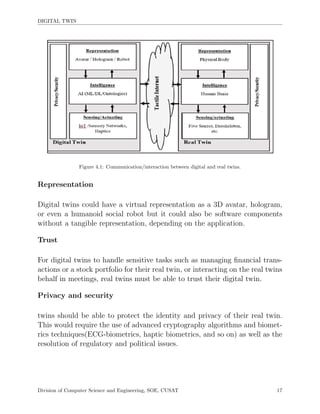

This seminar report discusses digital twins, which create living digital simulation models of physical assets. A digital twin continuously learns and updates itself from multiple real-time data sources to represent the current status of its corresponding physical twin. The report provides definitions of different types of digital twins and discusses how GE uses digital twins for applications like asset management, operations optimization, and advanced controls. It also covers the characteristics and advantages of digital twins, as well as examples of their use in various industrial sectors.