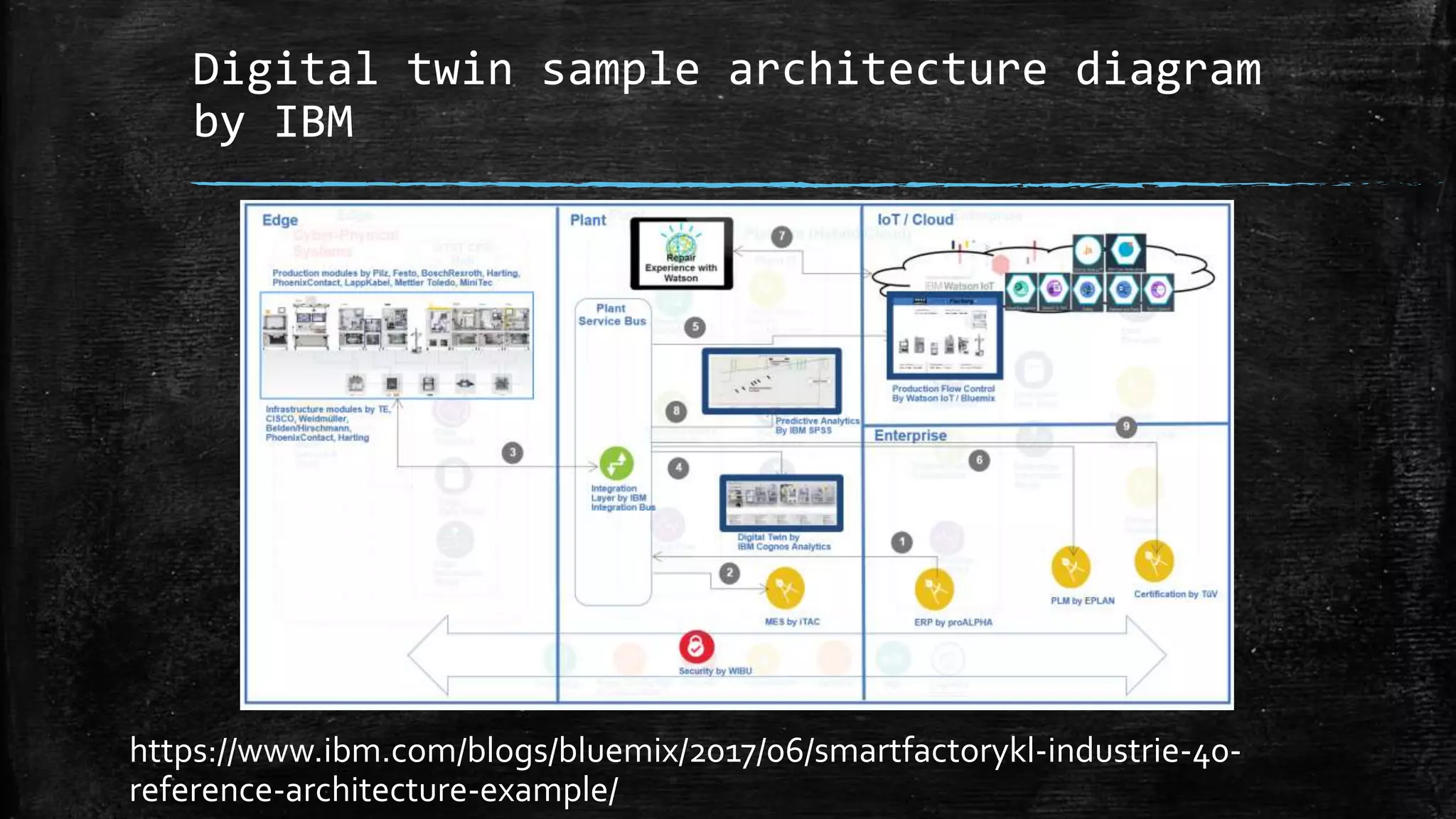

A digital twin is a virtual representation of a physical object that can be used to help optimize business decisions. The webinar discusses the history and definition of digital twins, how they are enabled by technologies like IoT, and how companies are using them. Digital twins allow a physical object and its virtual counterpart to be connected, providing a closed loop between the simulated and physical worlds to improve conceptualization, comparison, and remote collaboration.