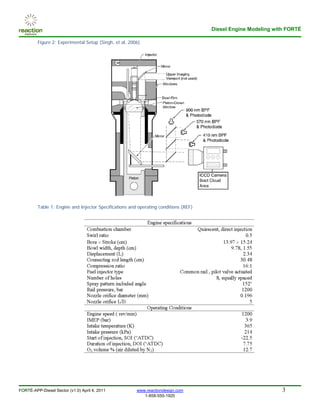

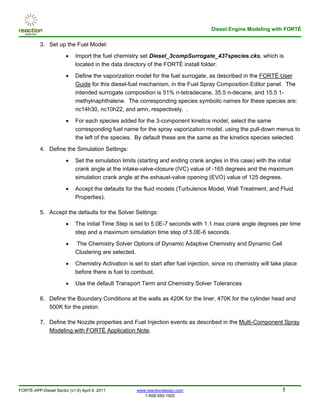

This application note details the use of the Forté CFD package for simulating diesel engine combustion using a multi-component fuel surrogate with 437 species. The setup includes advanced chemistry algorithms and modeling techniques to analyze ignition behavior and heat release, demonstrating strong alignment with experimental results. The document provides comprehensive instructions for setting up and running diesel combustion simulations effectively.