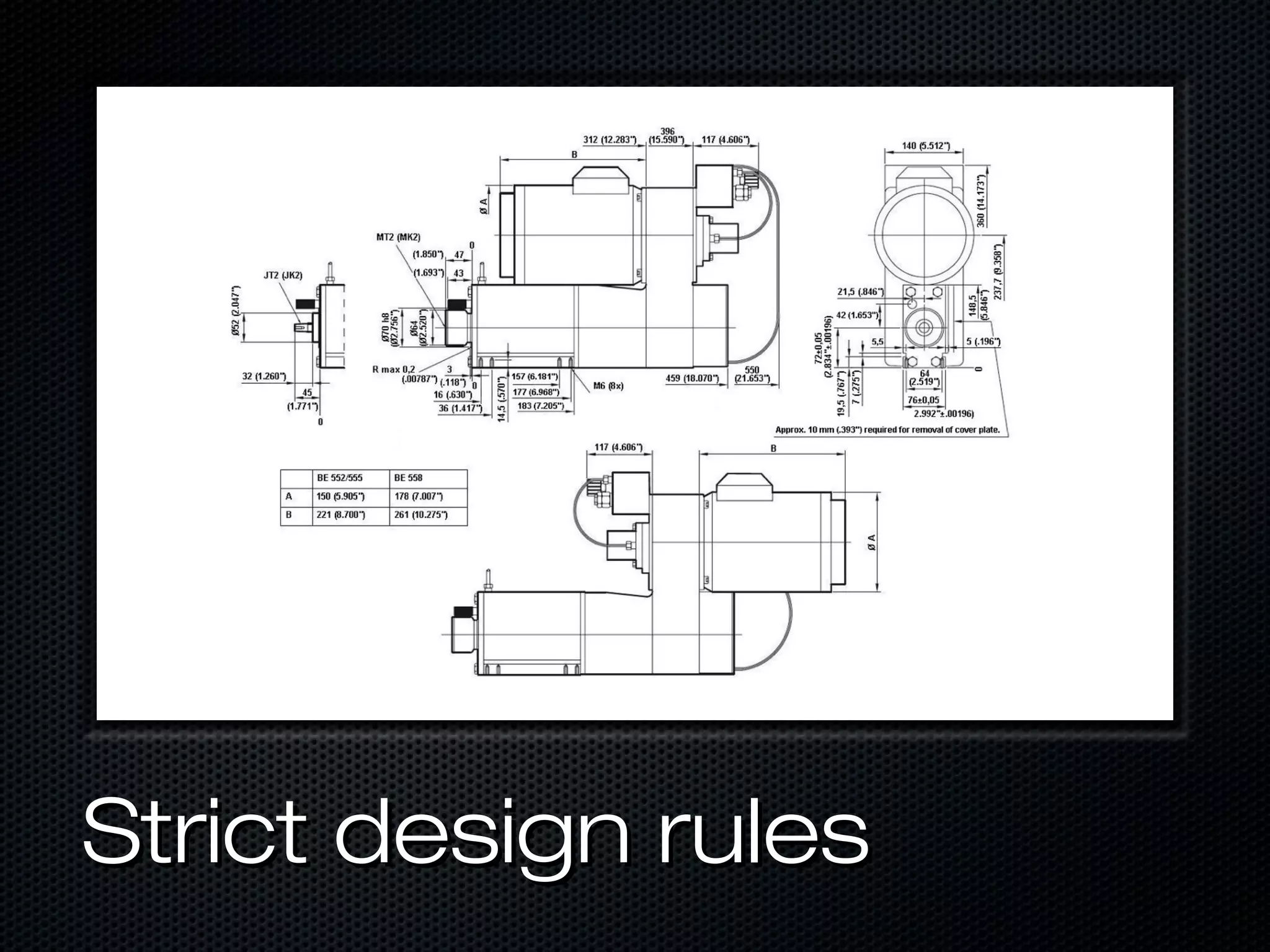

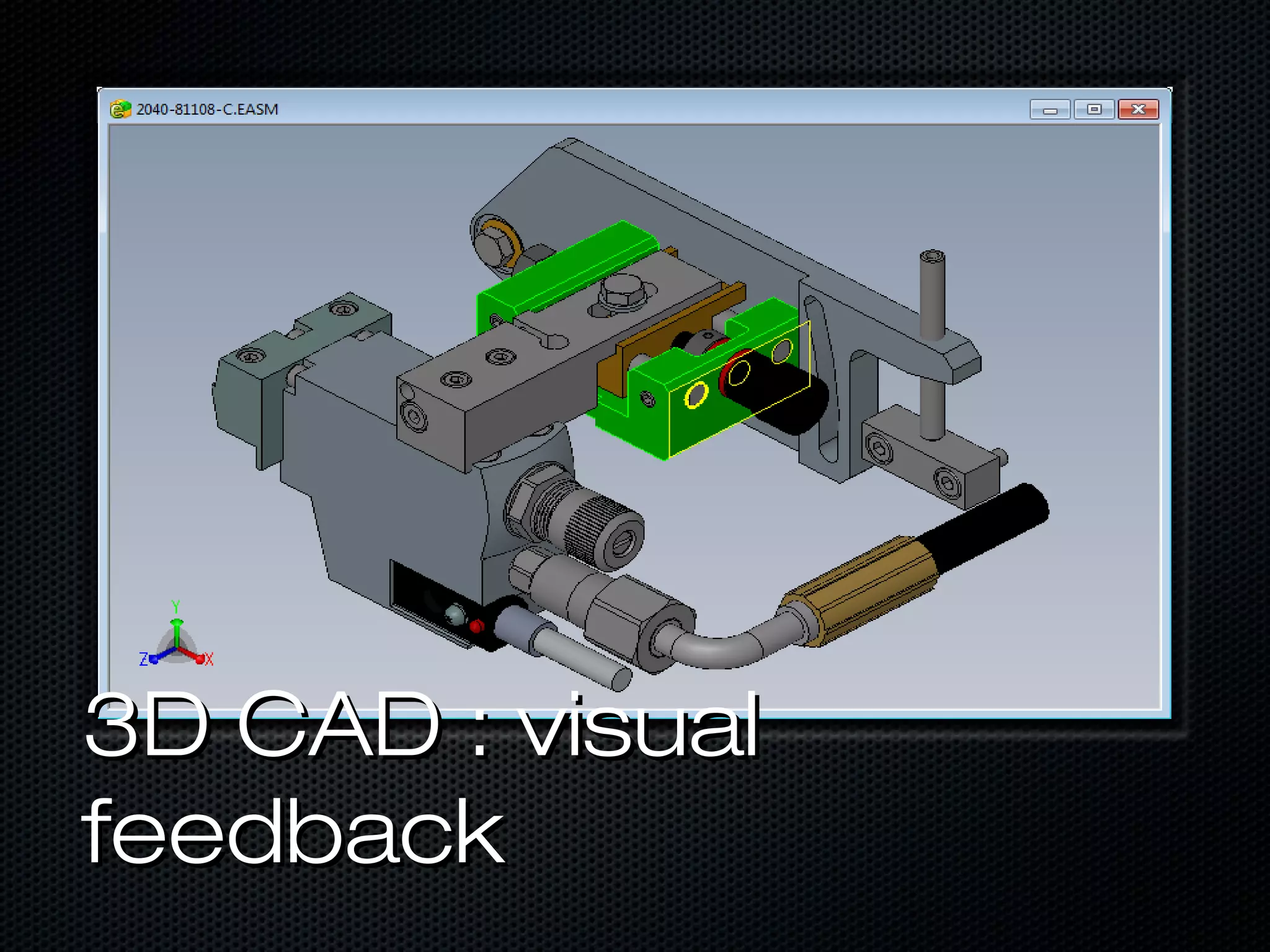

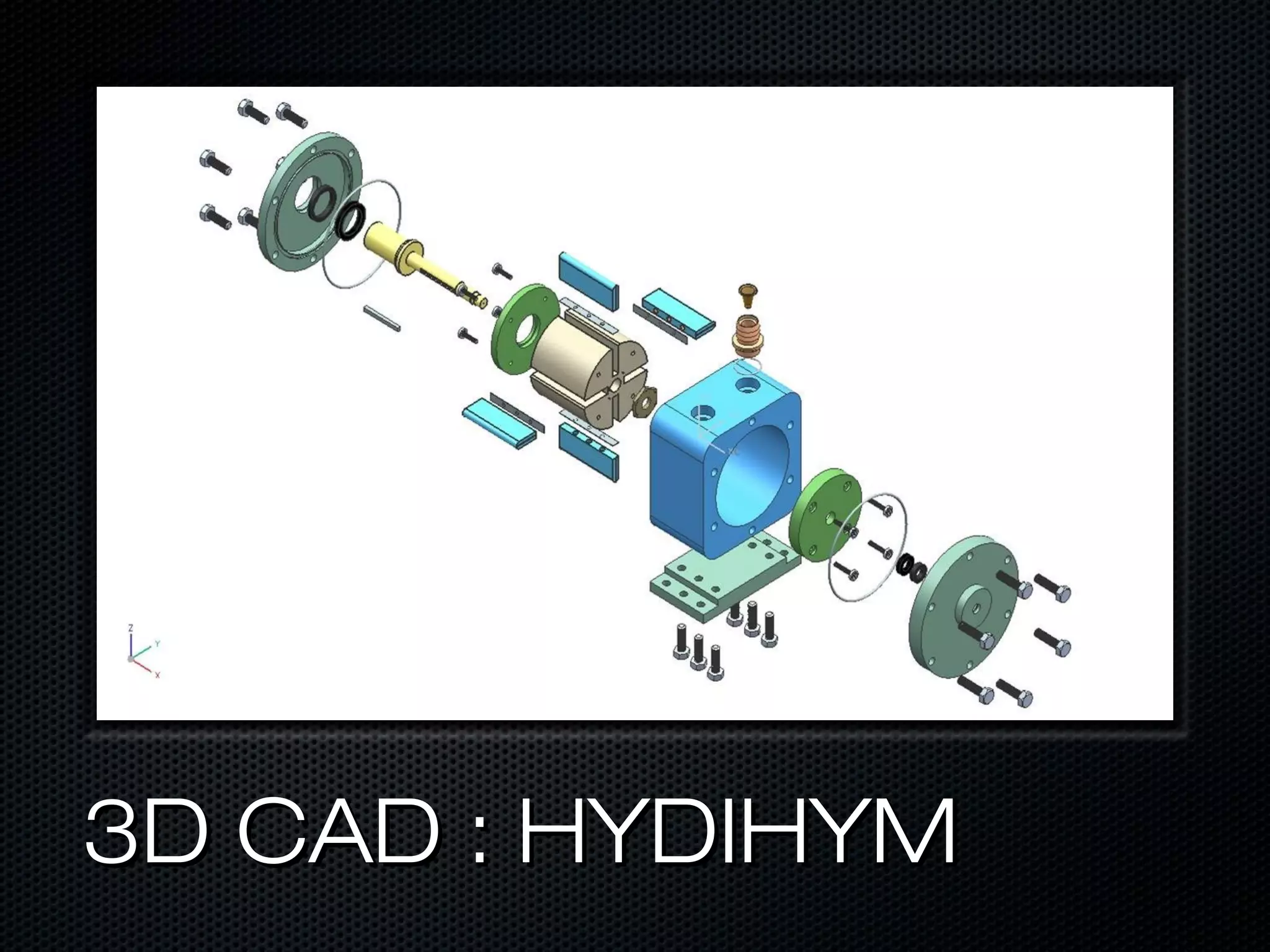

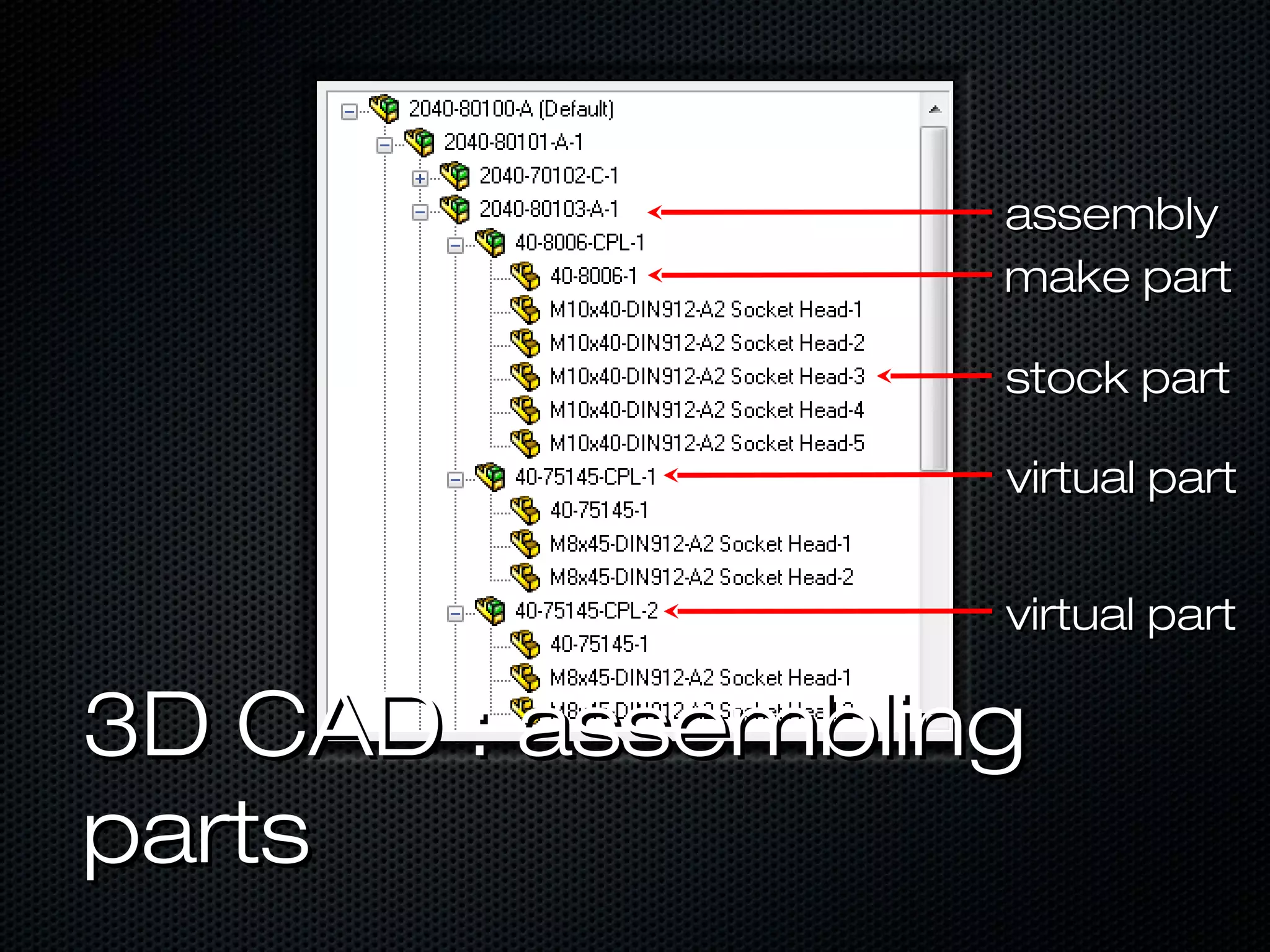

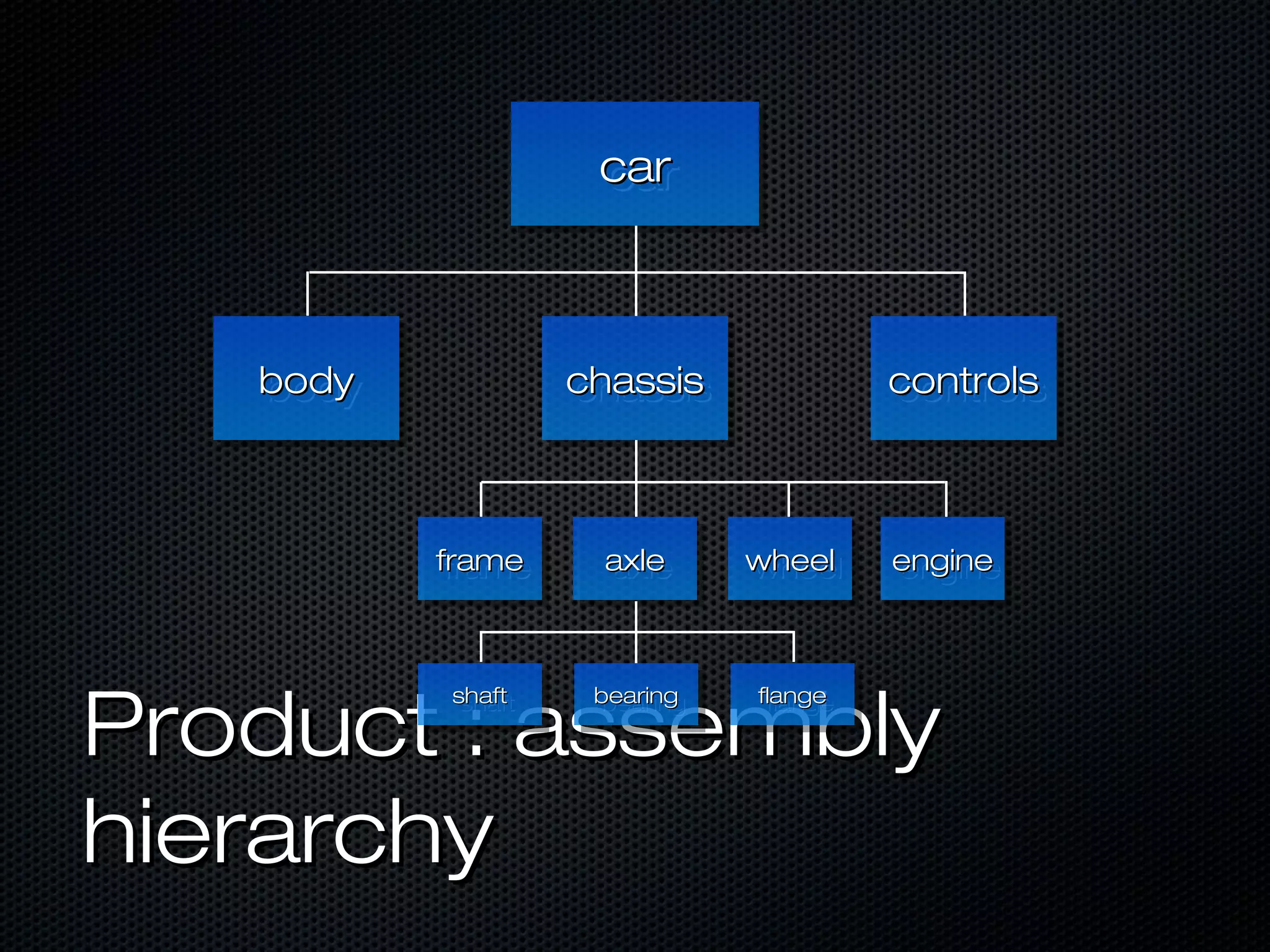

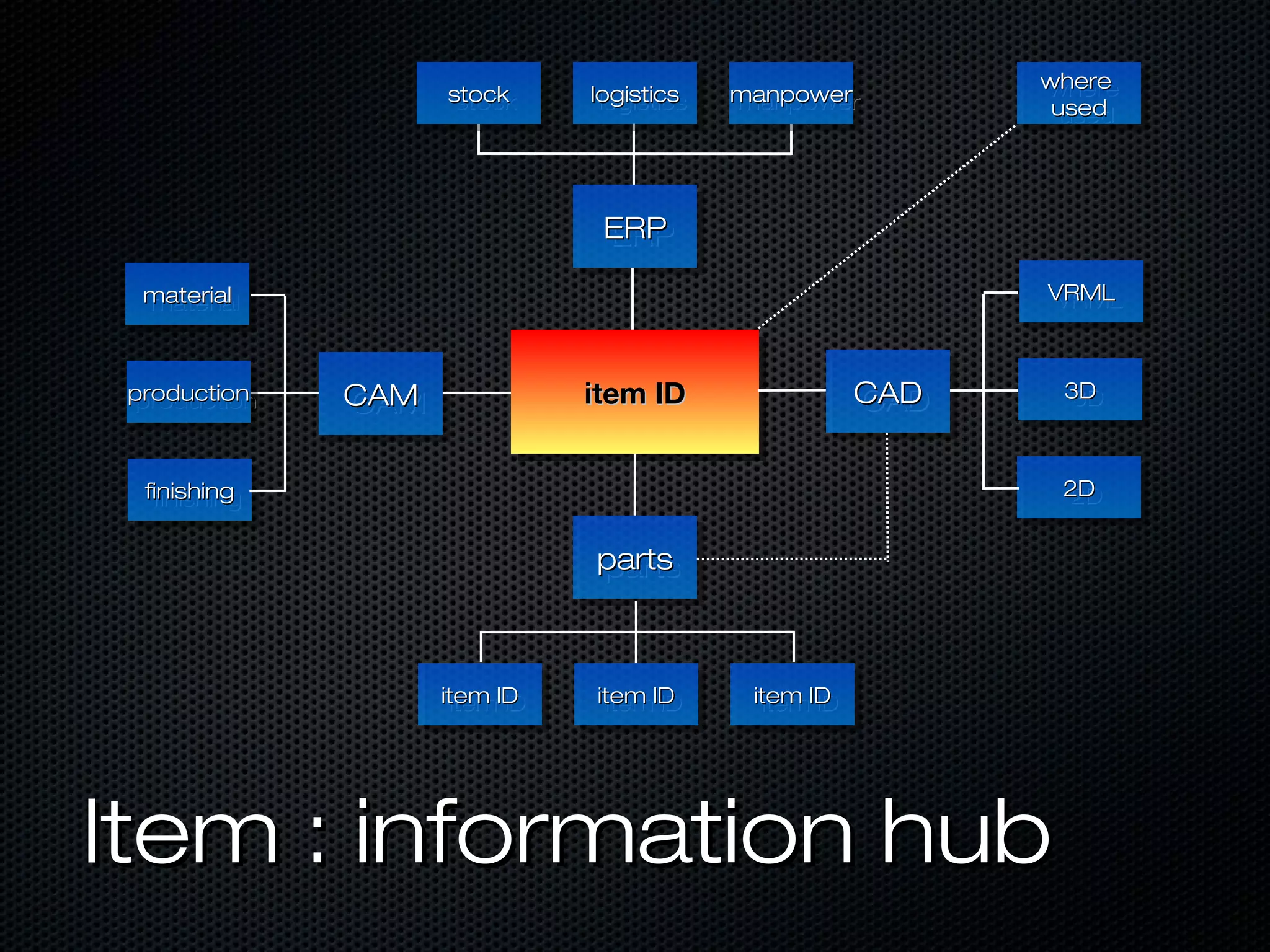

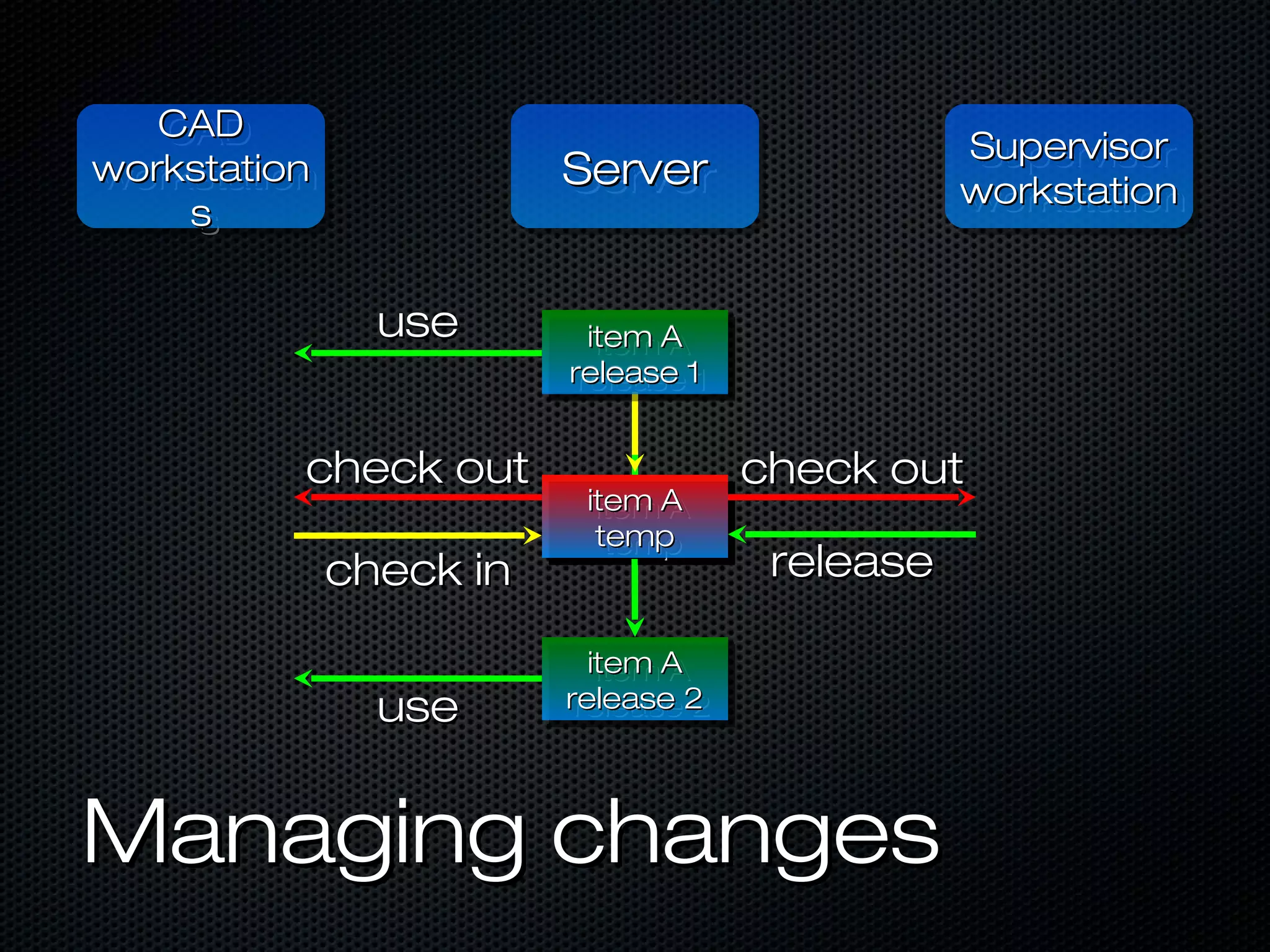

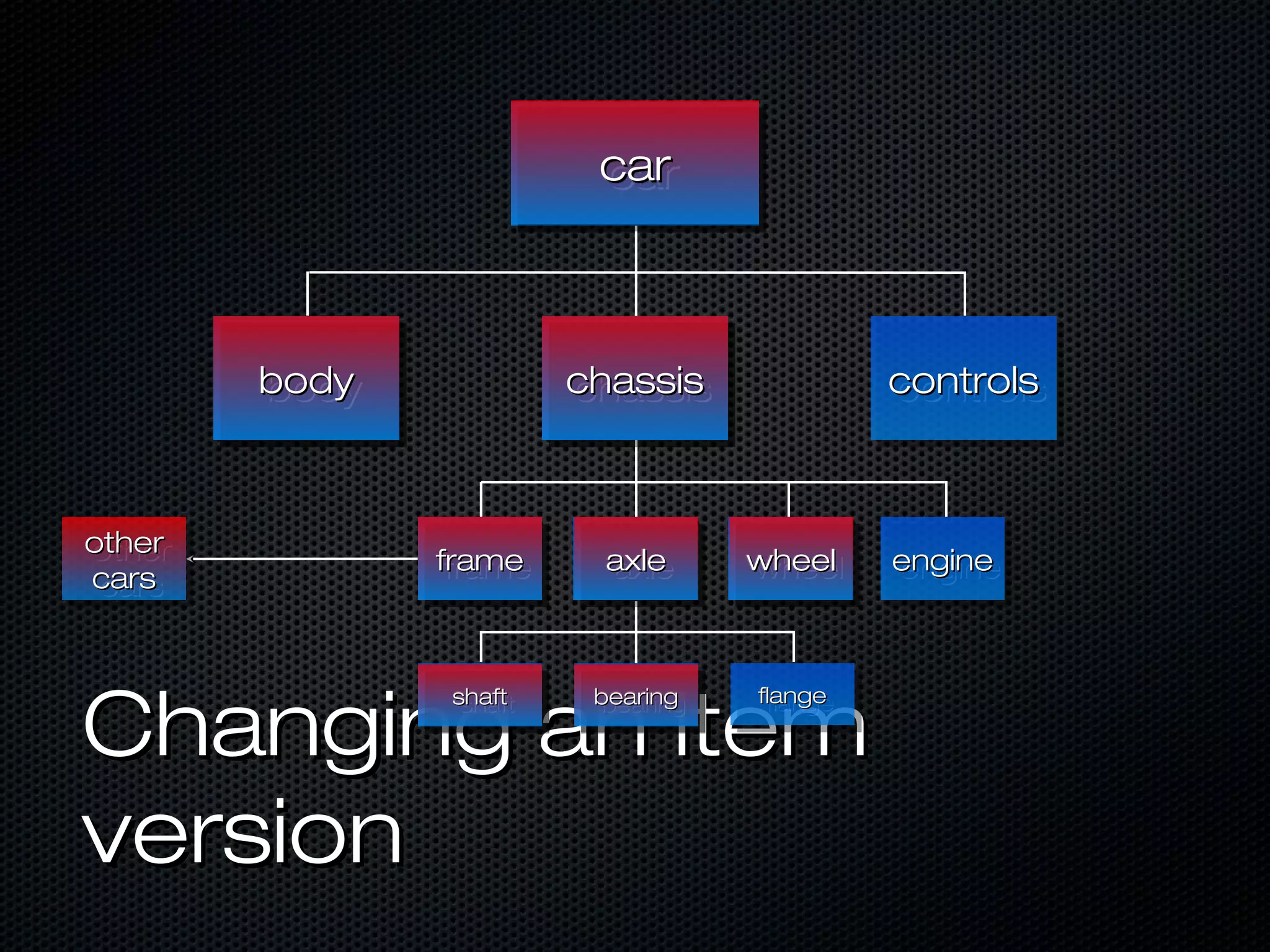

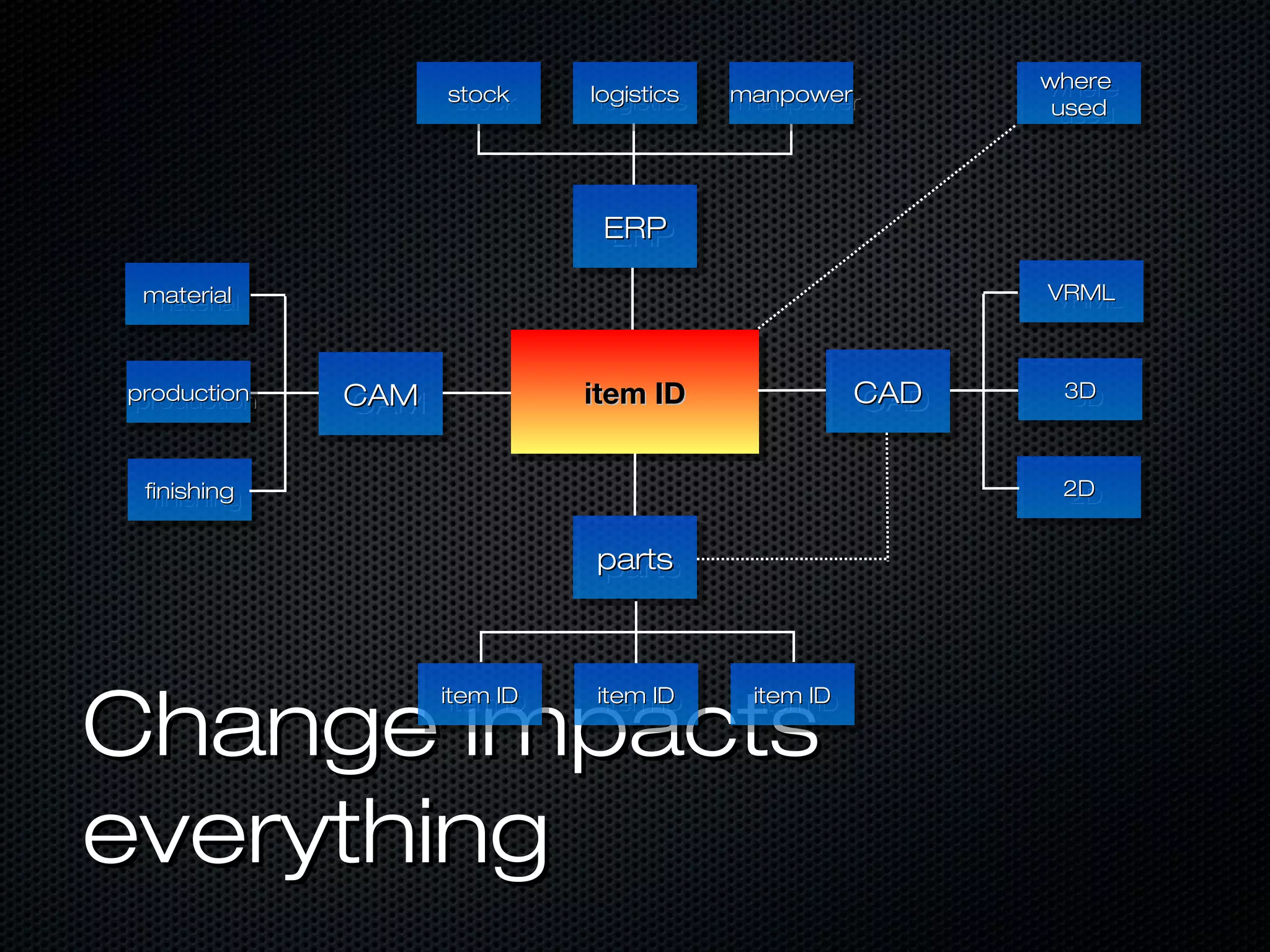

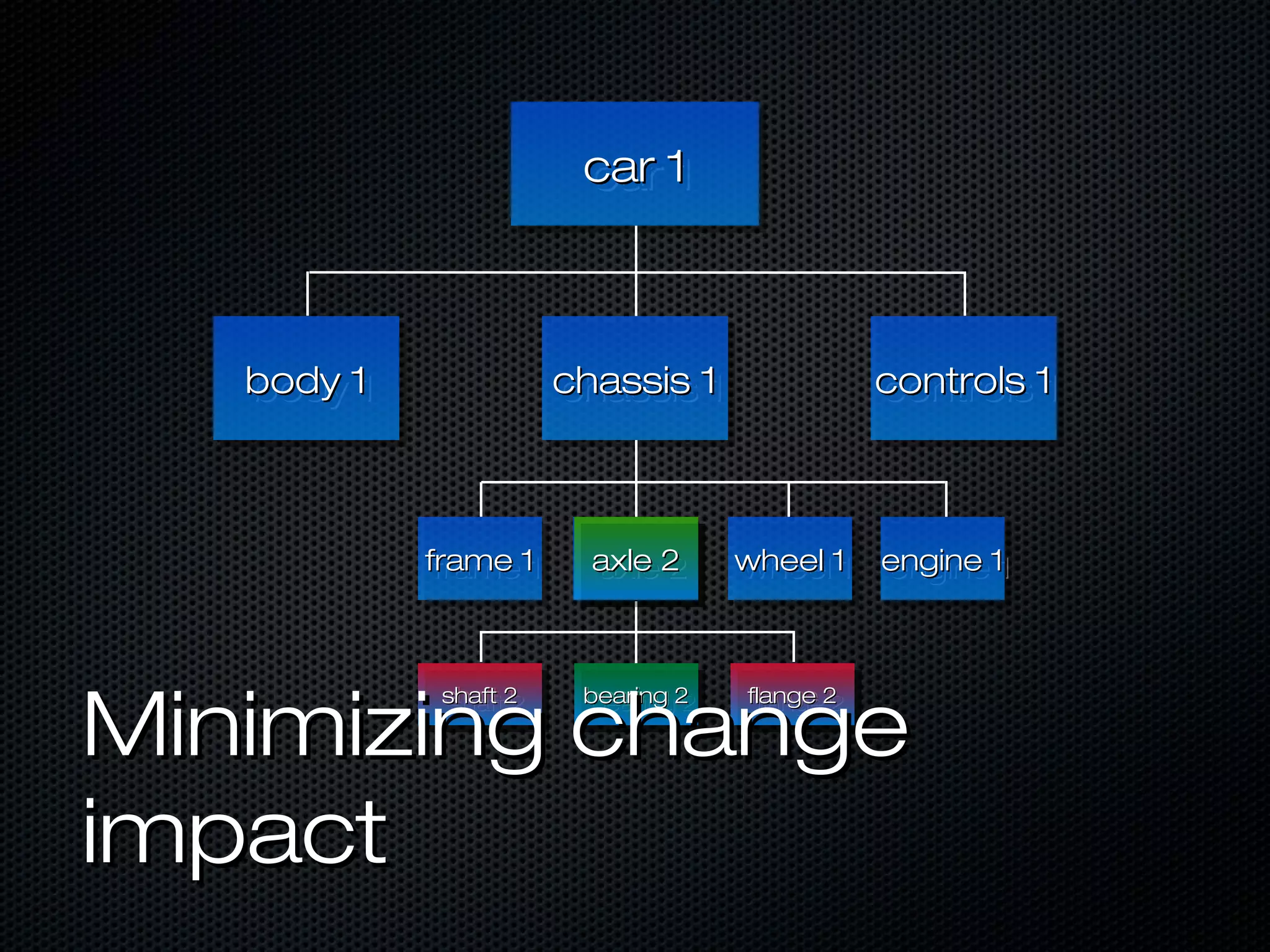

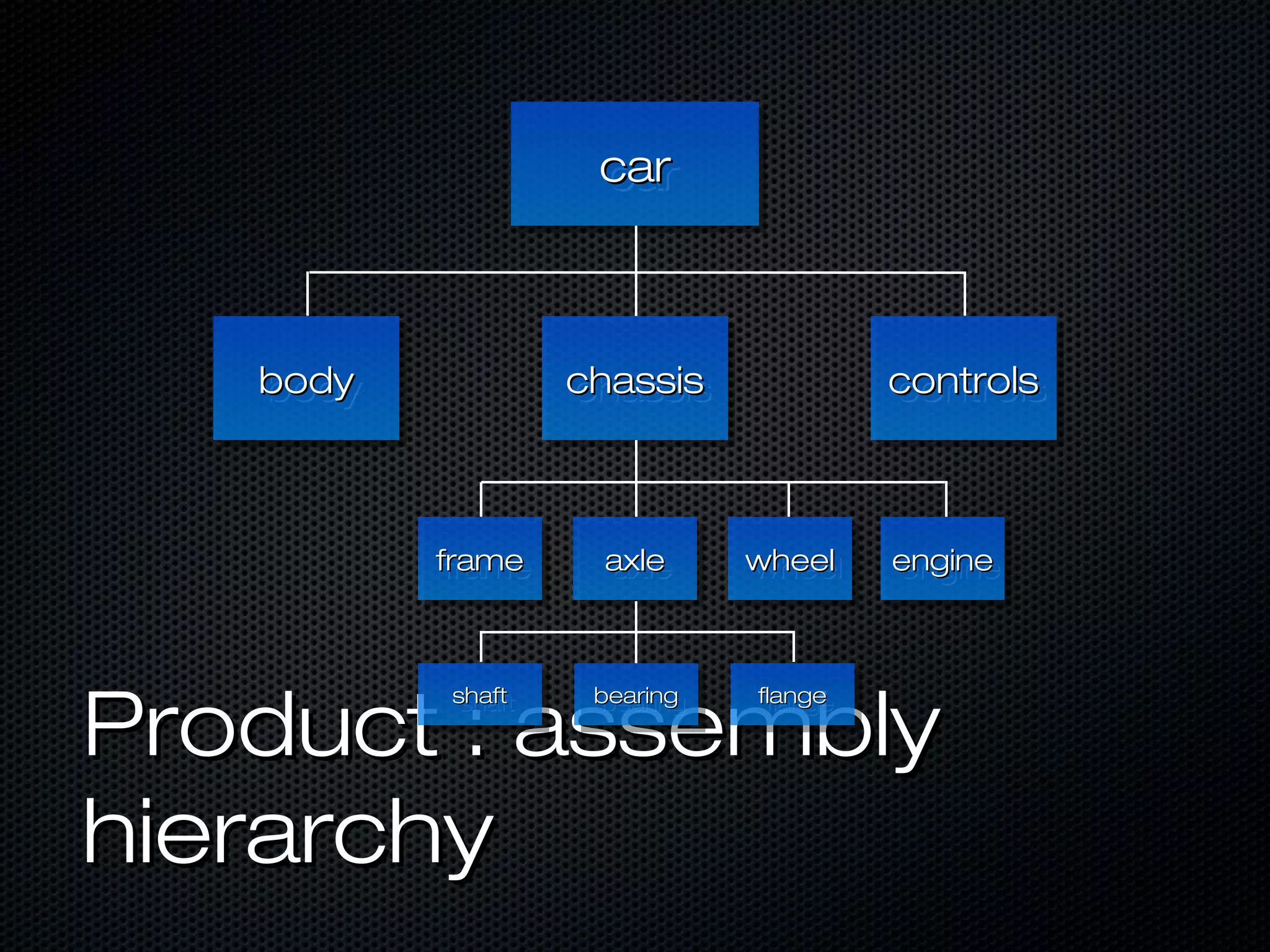

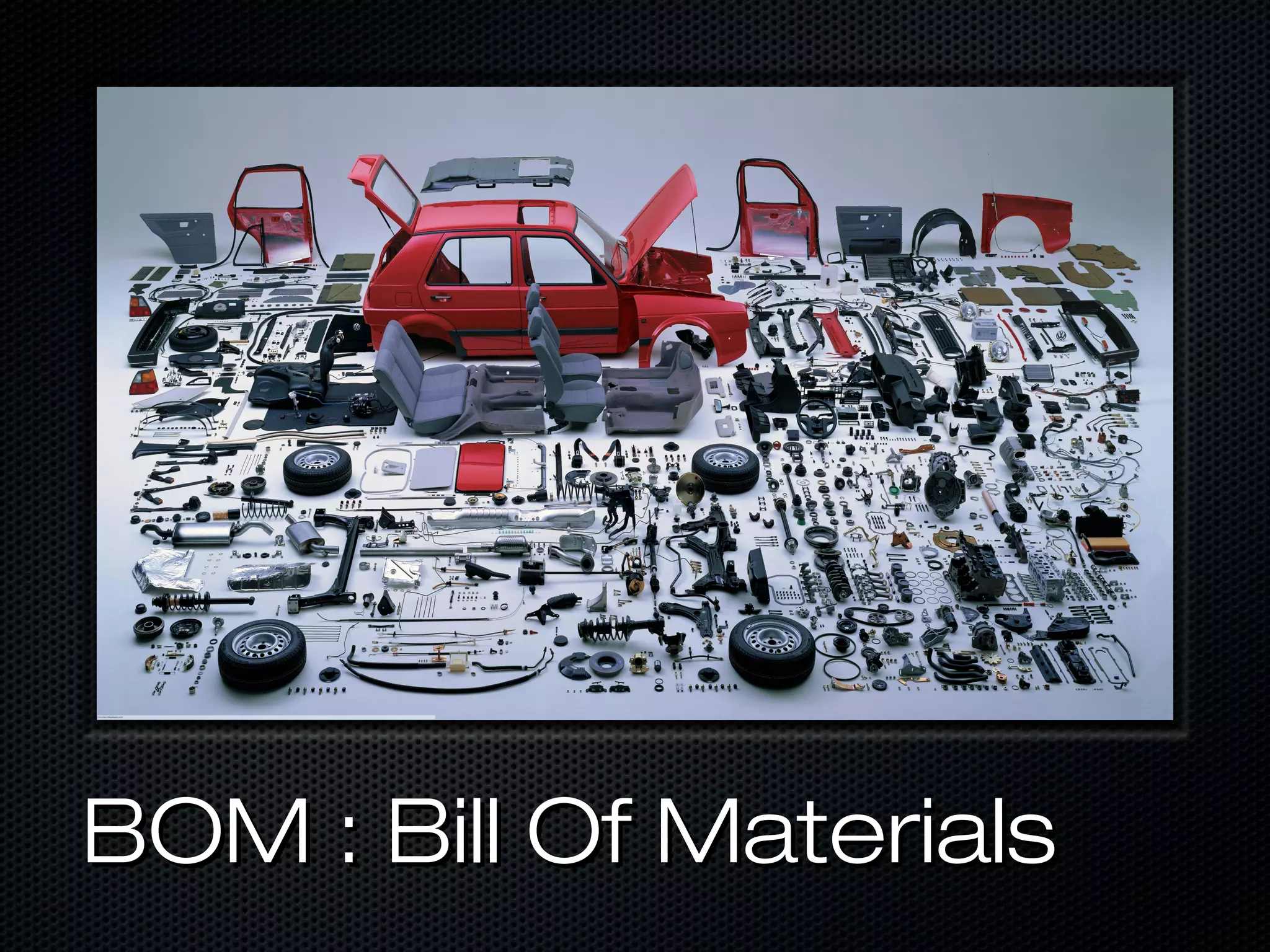

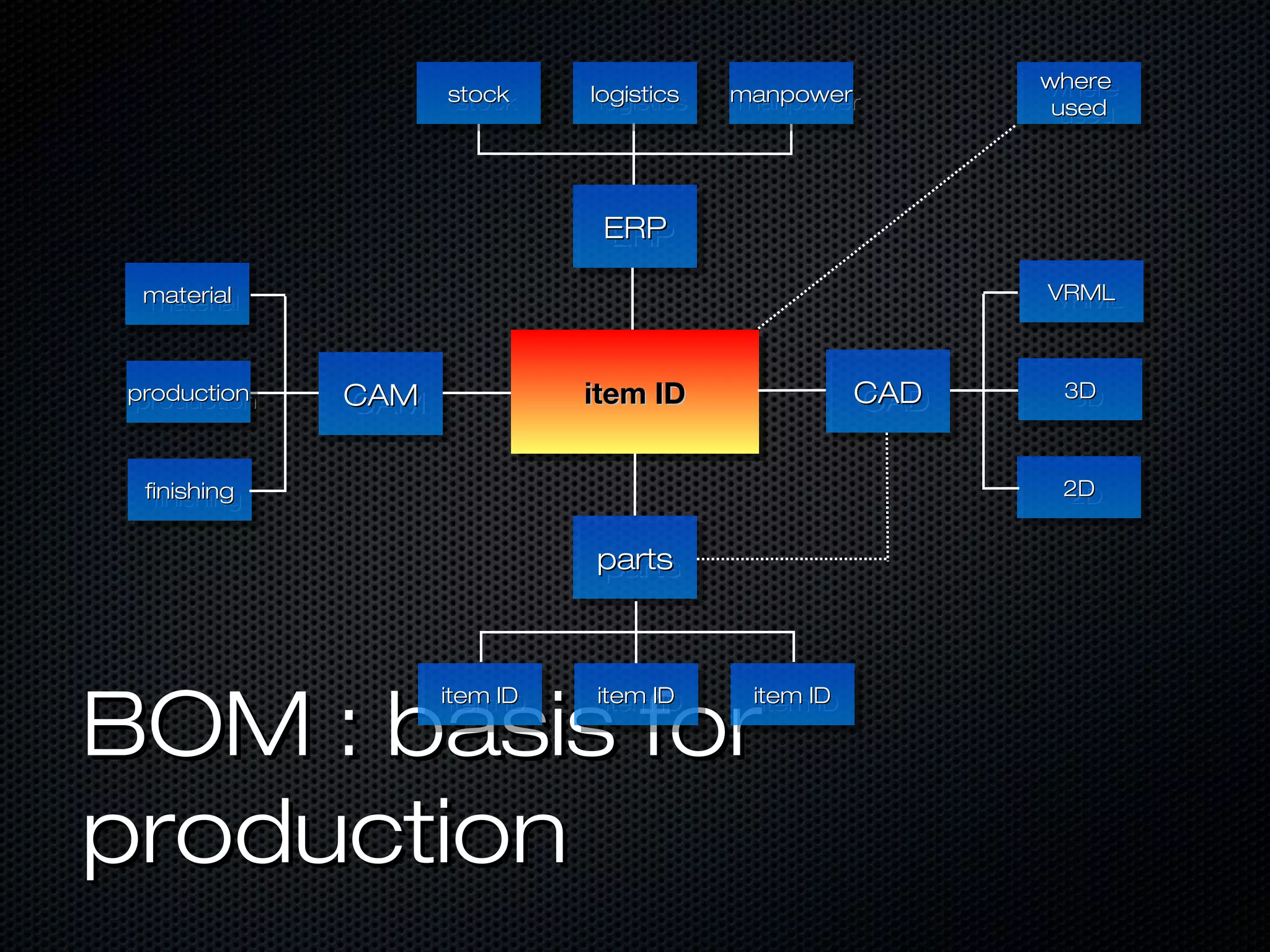

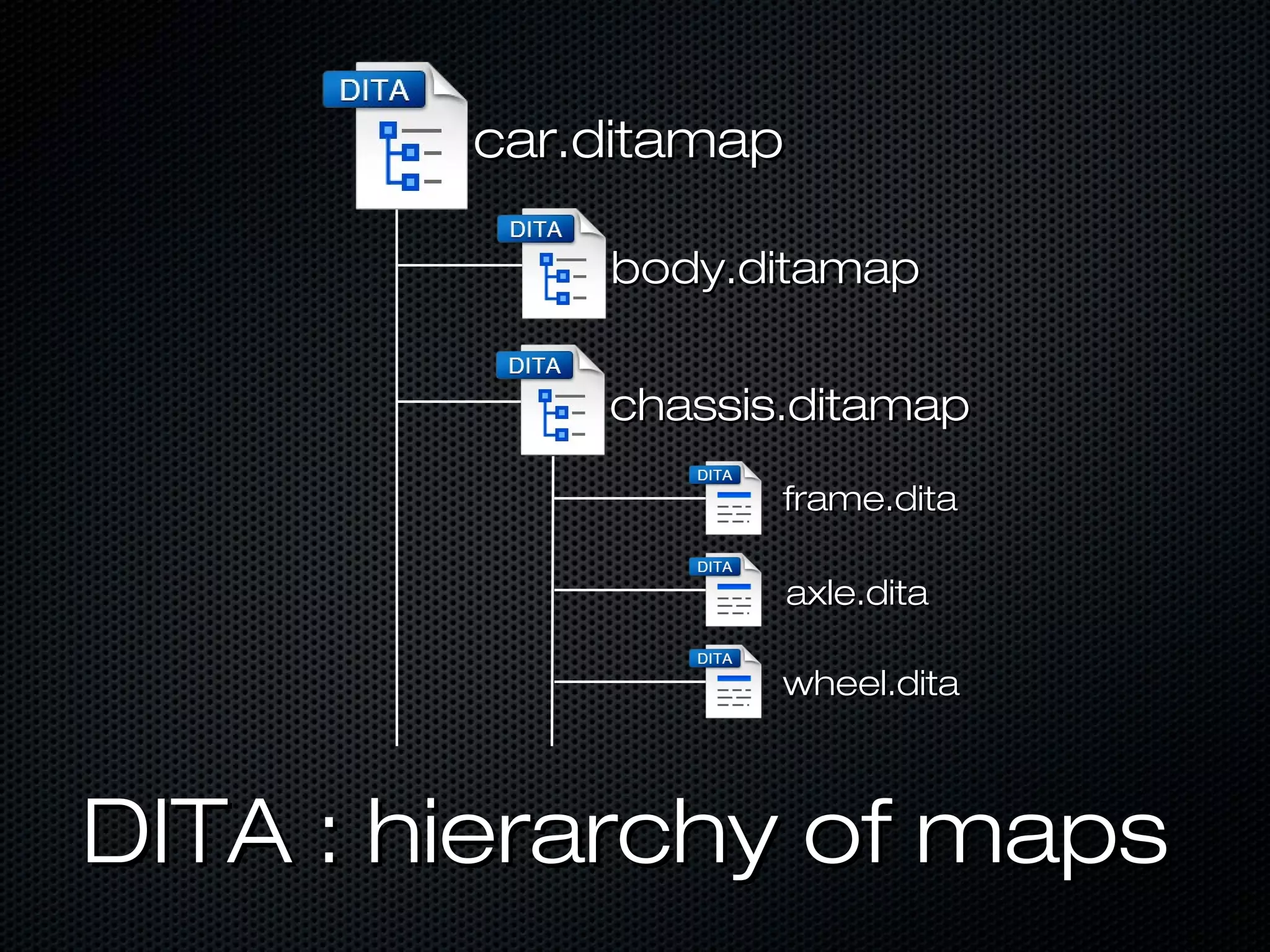

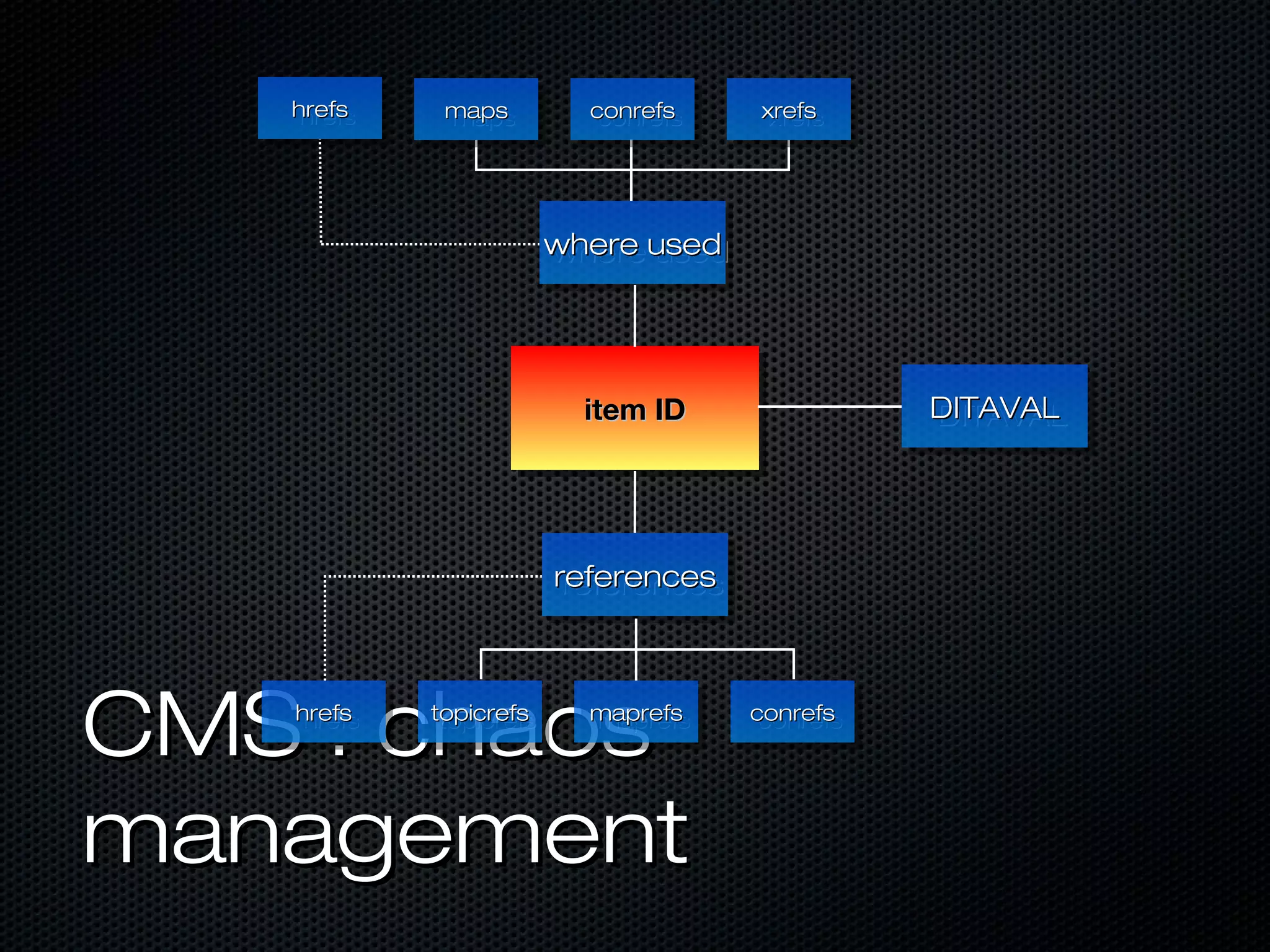

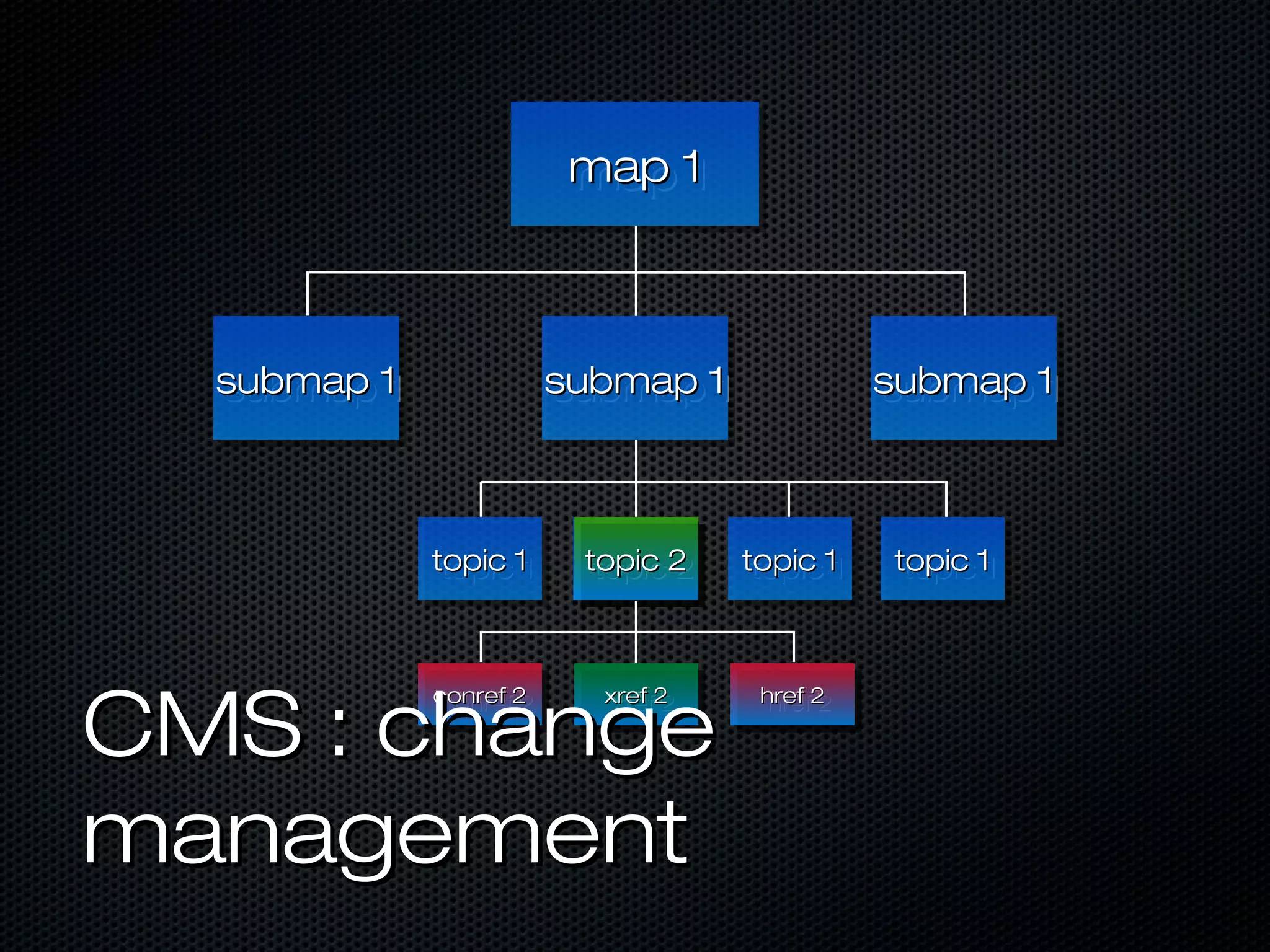

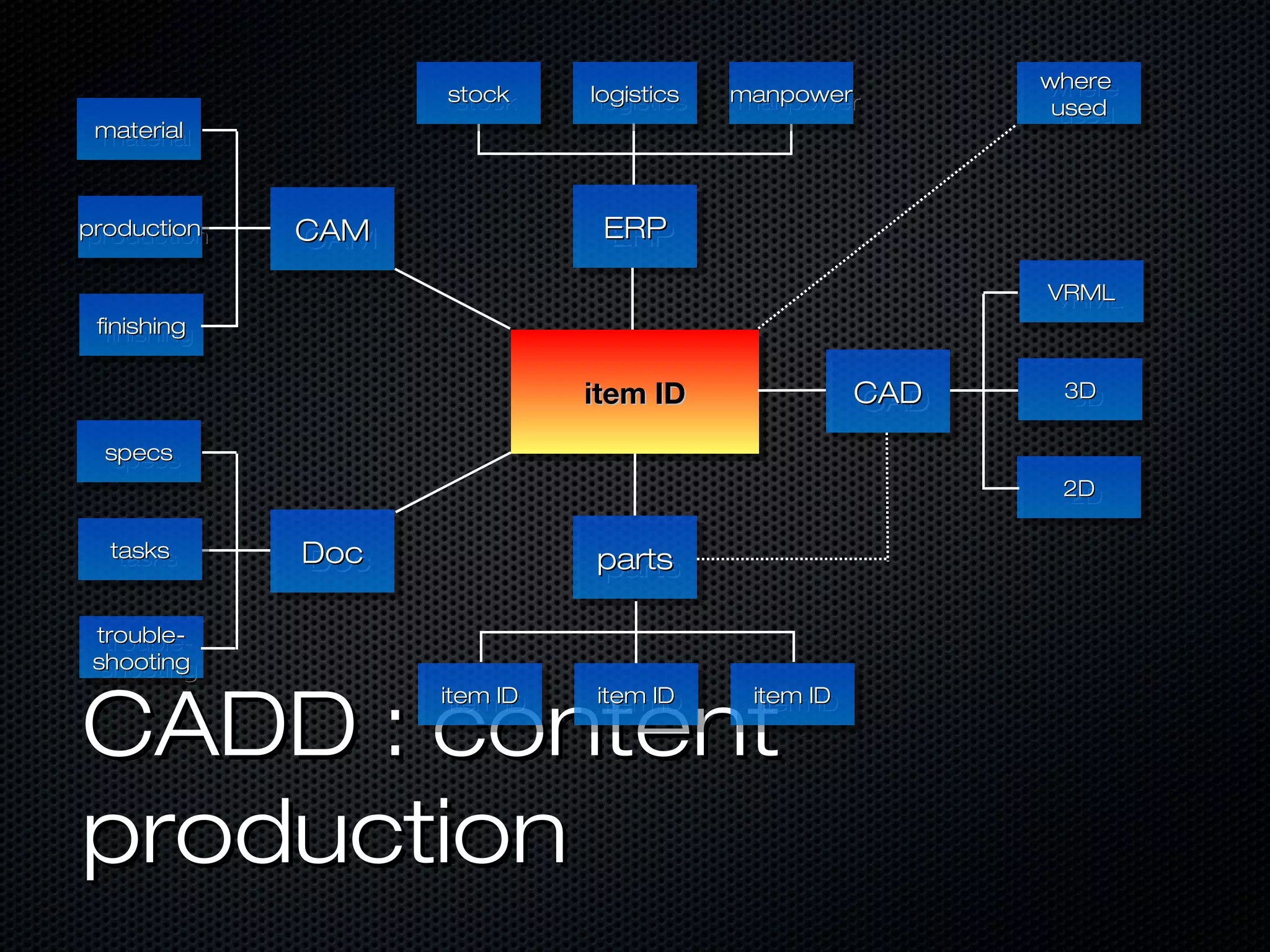

Computer-aided design (CAD) software uses hierarchies, assemblies, and reusable components to optimize design and manufacturing. Content authoring systems like DITA can learn from CAD approaches to improve reuse, change management, and production of technical documentation. CAD uses bills of materials (BOMs) that list all required parts to guide production; DITA can similarly use maps, topics, and relationships between them as the basis for manuals.