The document discusses the development of software for designing axial flow fans, focusing on improved efficiency for industrial applications. It utilizes blade momentum theory to create a user-friendly tool that can rapidly design and analyze fan performance, particularly for ducted fans in cooling towers. The software achieves close performance predictions and enables customization based on user requirements, facilitating easier and more cost-effective manufacturing processes.

![Abhishek Jain et. al.

2

Therefore, a simplified theoretical approach based on

isolated airfoil theory, called blade element theory,

rather than theories based on velocity triangles, can be

used. Similar theories are used for analysis and design

of propellers. To improve the accuracy, actuator disk

theory [1] and effect of interference between two

blades can be included.

In blade element theory, it is assumed that fan

consists of blades of airfoil shaped cross sections of

varying chord but vanishingly small size compared to

the radius at the various radial locations as in Fig. 1.

The forces on the airfoil section are calculated as lift

and drag coefficients based aerodynamic

characteristics of the chosen airfoil section. The two

dimensional loads are integrated along the radius to

calculate the thrust and torque on the blades. These

quantities are multiplied by an integer equal to the

number of blades in the fan. Thrust on the all the

blades is divided by the area swept by the blades to get

the total pressure rise across the fan by conservation.

The novel feature of the methodology incorporated in

the code is the interference effects from adjacent

blades in modifying the lift curve slope of the airfoil

by a factor considered in detail by Wallis [2].

3.1. Equations

An airfoil section of a blade of length R , at radial

distance r from the hub of the fan and a thickness dr

as illustrated in Fig. 2, obtained from [3], is considered

for analysis

Fig. 2: The lateral view of an axial flow fan showing

different flow parameters.

is the geometric pitch angle of the cross section, is the

angle of attack the flow makes with this cross-section.

lift and drag are the force vectors normal to and tangential to

the cross section

thrust, torque/radius are forces perpendicular and parallel to

the surface of the fan.

0V and 2V are the magnitudes of the axial and tangential

velocities of the flow at the section, 1V being their resultant

The difference in angle between thrust and lift directions is

given by =

The density of the air is

The Velocities 0V and 2V are obtained from the Mass

Flow Rate m and the Flow Angular Velocity at the

section

20

.. R

m

V

(1)

RV .2 (2)

From the velocity vector triangle 0V , 1V and 2V

2

2

2

01 VVV (3)

2

0

tan

V

V

a (4)

From the force vector triangle, the torque/radius is

observed to be

)sin()cos( LDQ (5)

The flow angular velocity is then obtained from the

torque/radius

R

m

Q

.

(6)

Fig. 1: The blades of an axial flow fan are assumed

to be made of airfoil shaped cross sections with the

same airfoil throughout but different with chord

lengths at different radial positions](https://image.slidesharecdn.com/research-paper-on-development-of-software-for-sizing-of-axial-flow-fans-201118072932/75/Development-of-Software-for-Sizing-of-Axial-Flow-Fans-Zeus-Numerix-2-2048.jpg)

![Development of Software for Sizing of Axial Flow Fans

3

RVdrR

Q

...2 0

(7)

There now exists a nonlinear system of equations (1),

(2), (3), (4), (5), and (7) containing the primary

unknown variables Q , , , 2V and 1V . So, an

iterative solution to this system is possible by initially

substituting by the Fan Angular Velocity f . The

torque thus obtained is for a single section. The torque

on the whole blade is then obtained by adding the

elemental quantity and Q for all the sections.

4. RESULTS AND DISCUSSION

The software has been configured to: (1) Design of

high efficiency fan (2) Off-design analysis of a fan, (3)

Performance prediction of fan made of given blades.

For design the user requirements are to be known.

These are dictated usually by the space constraint,

amount of heat to be taken out, availability of pre-

manufactured components, manufacturability of airfoil

sections, availability of motor and gear ratios etc.

These constraints in turn technically decide (a) total

and hub diameter, (b) volume flow rate, (c) pressure

rise, (d) rpm, (e) airfoil section and (f) number of

blades (g) bounds of angle of attack.

The software has an automatic module for trying

various settings to arrive at the performance of the fan

for maximum efficiency. The fan can then be exported

to AutoCAD DXF file format in 3D and each section

to be provided directly to the manufacturing process.

Besides efficiency which is the main concern, the

software also provides the torque, thrust, power

required and the sound level.

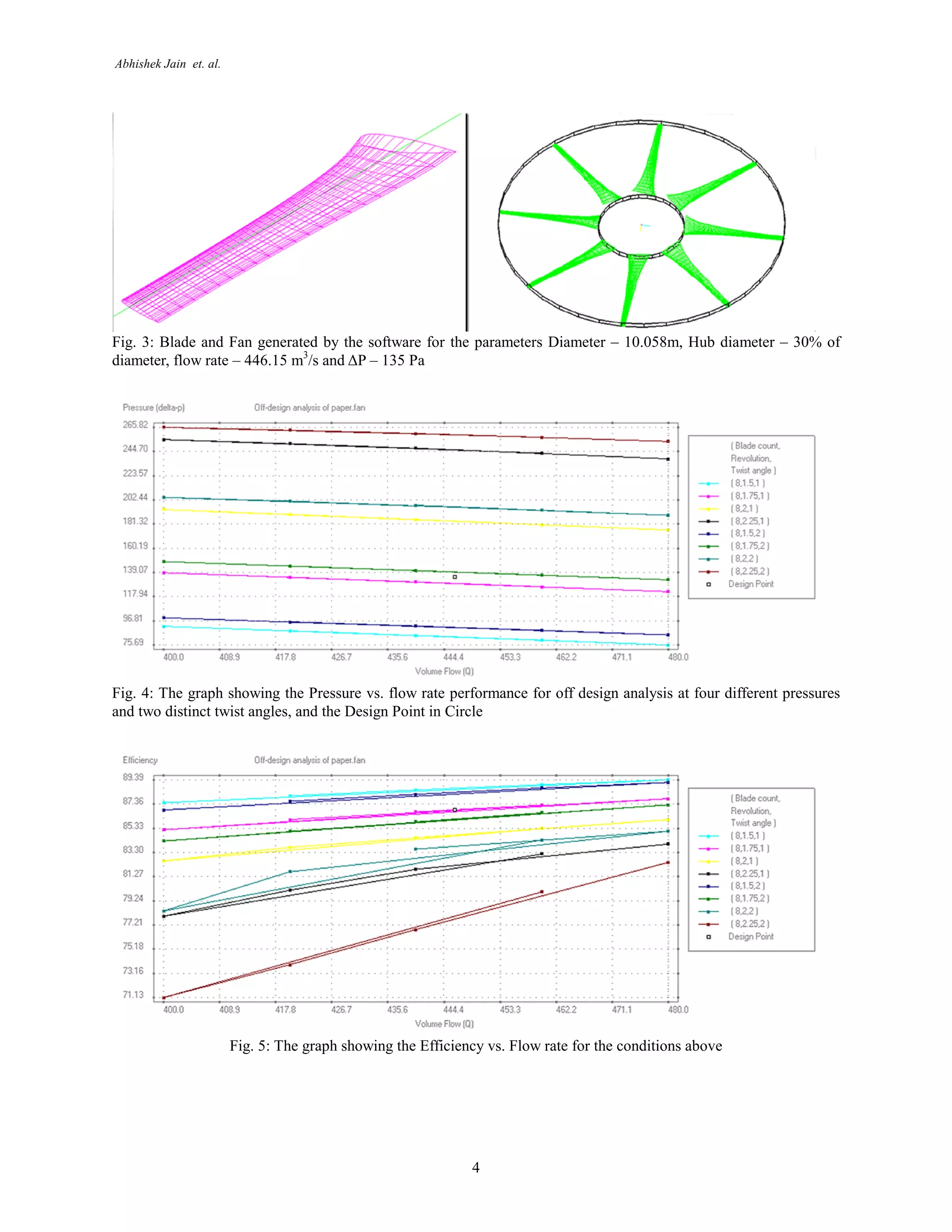

4.1. Fan Design

Cooling tower fan has been designed using the inputs

as given: Diameter – 10.058m, Hub diameter – 30% of

diameter, flow rate – 446.15 m3

/s and ΔP – 135 Pa. It

has been seen that 23012 airfoil is suitable for these

shapes and hence that same has been used to design the

fan. Maximum efficiency possible predicted has been

86.84%. In practice it has been seen that the results

have been consistently over predicted by 5-7% based

on the actual efficiency measured. It is important that

the over prediction is consistent and hence the designer

is in the know of actual efficiency. Fig. 3 shows the

blade of the fan and the fan that is generated for the

above case.

4.2. Off-design performance

Industry does not always have the same performance

requirement from the fan. Change in the heat load may

require significant alteration on the working of the fan

e.g. lower heat production may require the fan to

temporarily slow down. Performance of the fan in

these conditions has to be studied and the same has

been done for variation of various properties. The

design can be obtained for a variety of RPMs, flow

rates and a typical result is shown in Fig. 4. The graph

contains a pressure vs. flow rate for variation of five

flow rates, two additional twists and four different

rotational speeds. Fig. 5 shows the same for efficiency

vs. flow rate.

5. CONCLUSIONS

It is seen that the design of low speed axial fans with

cooling tower and other flow applications is possible.

The implemented procedure has been tested and the

manufactured fans show a predictable behavior

compared to the theoretical data. With the proving of

base codes it is advisable to extend the methodology to

other applications of axial flow such as small diameter

fans, propellers at high speed and possibly to radial

flow applications. No marked difference has been seen

with the variation of number of blades in the

performance of the fan. The same has been reported in

[4].

6. REFERENCES

[1] Ingram, Grant. "Wind Turbine Blade Analysis

using the Blade Element Momentum Method. Version

1.0." (2005): 1-21.

[2] Wallis, R. A., and F. I. E. Aust. "A Rationalized

Approach to Blade Element Design, Axial Flow Fans.

Institute of Engineers." Australia Conference on

Hydraulic and Fluid Mechanics. 1968.

[3] D.J, Auld, and Srinivas K. "Aerodynamics for

Students." Aerodynamics for Students. University of

Sydney, n.d. Web.

[4] “Basics of Axial flow Fans”, M0100-186 5M

W1/00, Hudson Product Corporation, 2000](https://image.slidesharecdn.com/research-paper-on-development-of-software-for-sizing-of-axial-flow-fans-201118072932/75/Development-of-Software-for-Sizing-of-Axial-Flow-Fans-Zeus-Numerix-3-2048.jpg)