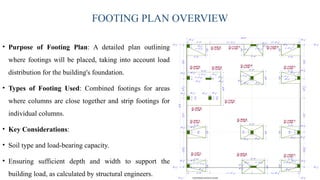

The document presents a detailed overview of a residential building construction project undertaken by students as part of their civil engineering degree, focusing on various aspects such as site analysis, construction planning, and safety measures. It describes the construction processes, including layout, footing, shuttering, structural reinforcement, and installation of electrical and plumbing systems, all aimed at optimizing energy efficiency and ensuring safety. Challenges faced during the project, such as weather delays and material shortages, are also addressed, highlighting the practical learning experiences gained during the internship.