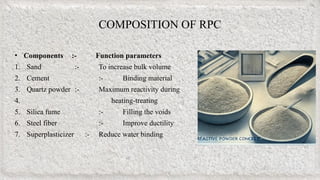

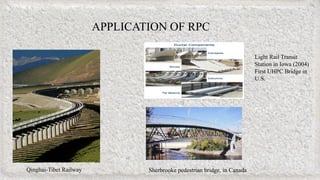

The document is a presentation on Reactive Powder Concrete (RPC), detailing its composition, applications, properties, and economic and environmental aspects. RPC is characterized by exceptional strength and durability, with compressive strengths ranging from 200 to 800 MPa, and has potential applications in critical infrastructure projects. Future research aims to enhance workability, reduce costs, and incorporate eco-friendly materials to improve RPC's sustainability.