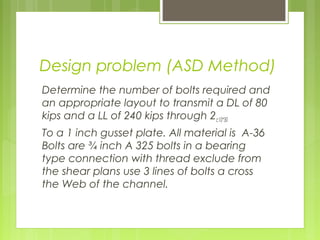

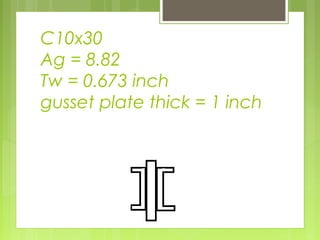

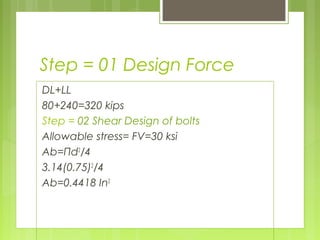

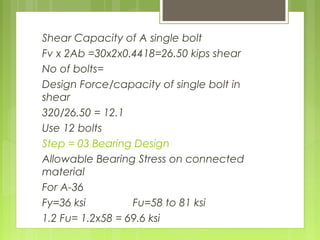

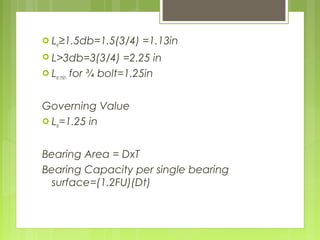

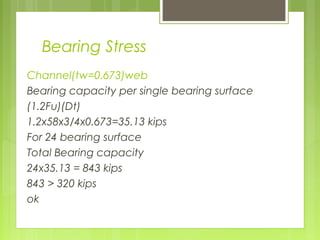

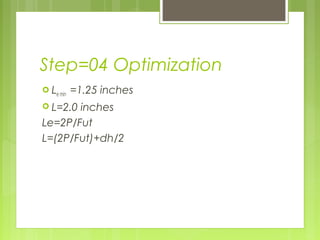

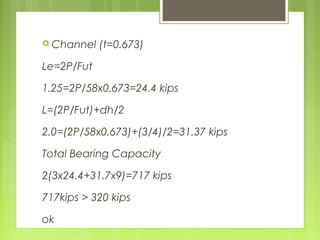

This document summarizes the design of a steel connection using bolts to transmit loads through a C10x30 channel to a 1-inch thick gusset plate. It determines that 12 3/4-inch A325 bolts in a bearing connection are required. It also checks that the bolts and the channel web and gusset plate meet bearing capacity requirements, with factors of safety above the 320 kip total load. Optimization of the bolt layout confirms bearing capacities of 717 kips for the channel and 533 kips for the gusset plate, sufficient for the load.