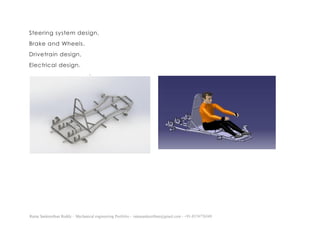

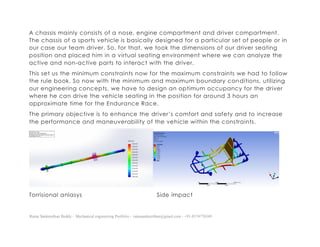

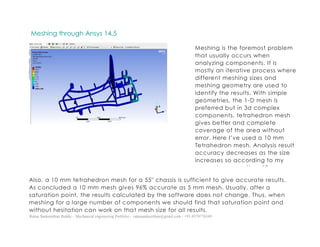

The document describes the design process of a customized rear engine go-kart. It discusses dividing the work into sub-teams for chassis design, body, steering, drivetrain etc. It provides details of the chassis design process involving defining dimensions based on the driver, performing analyses like impact and torsion tests, and ensuring ergonomics and safety. The summary highlights the key stages and considerations of the go-kart design process.