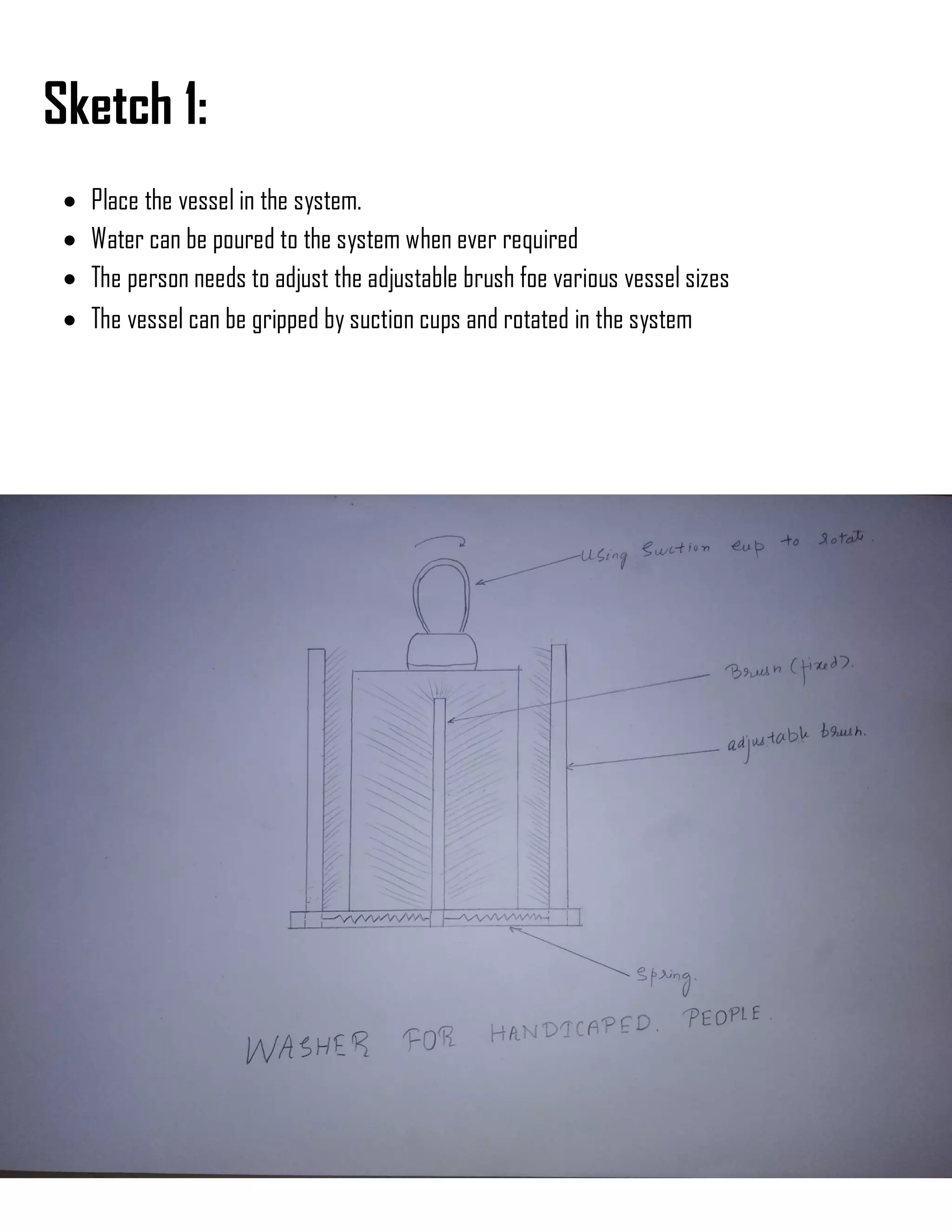

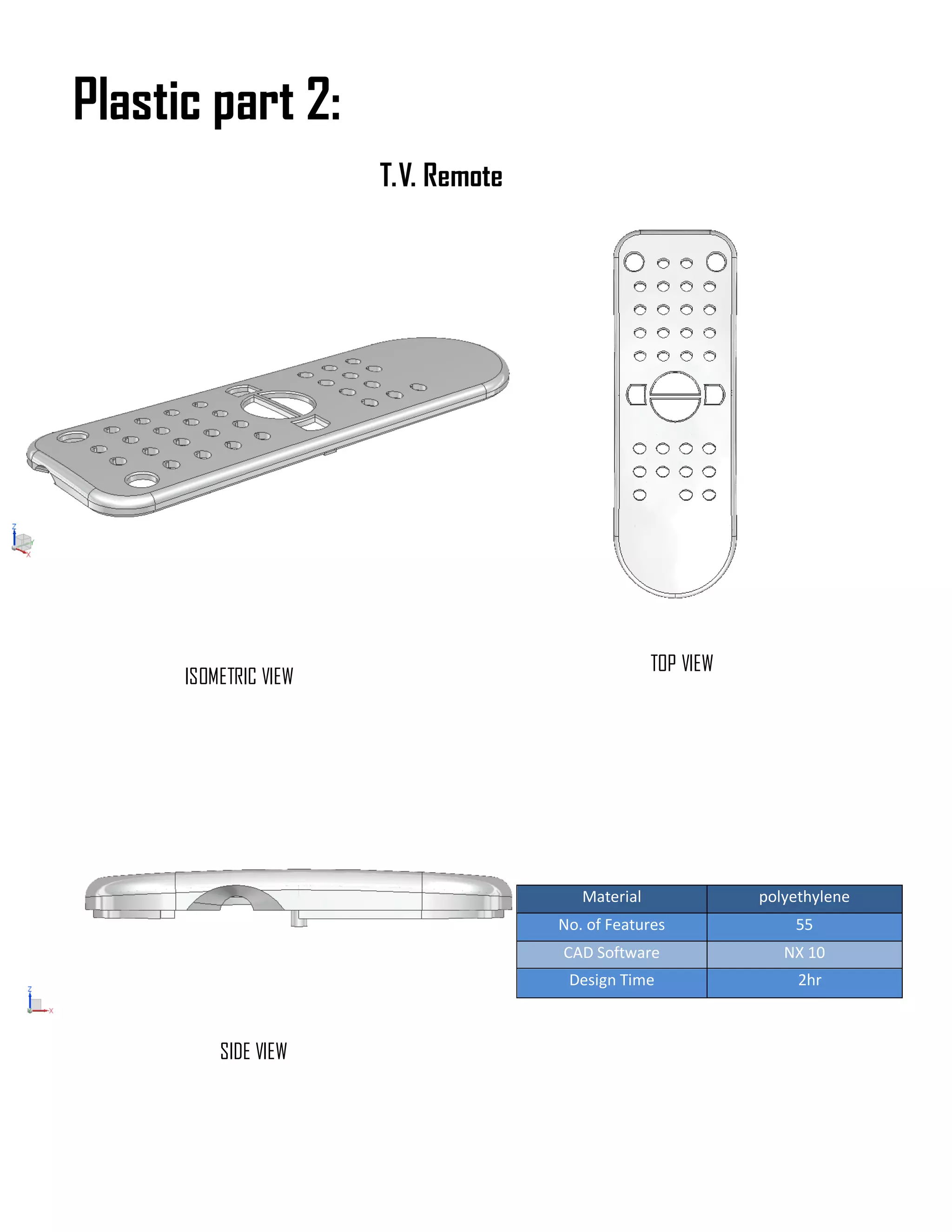

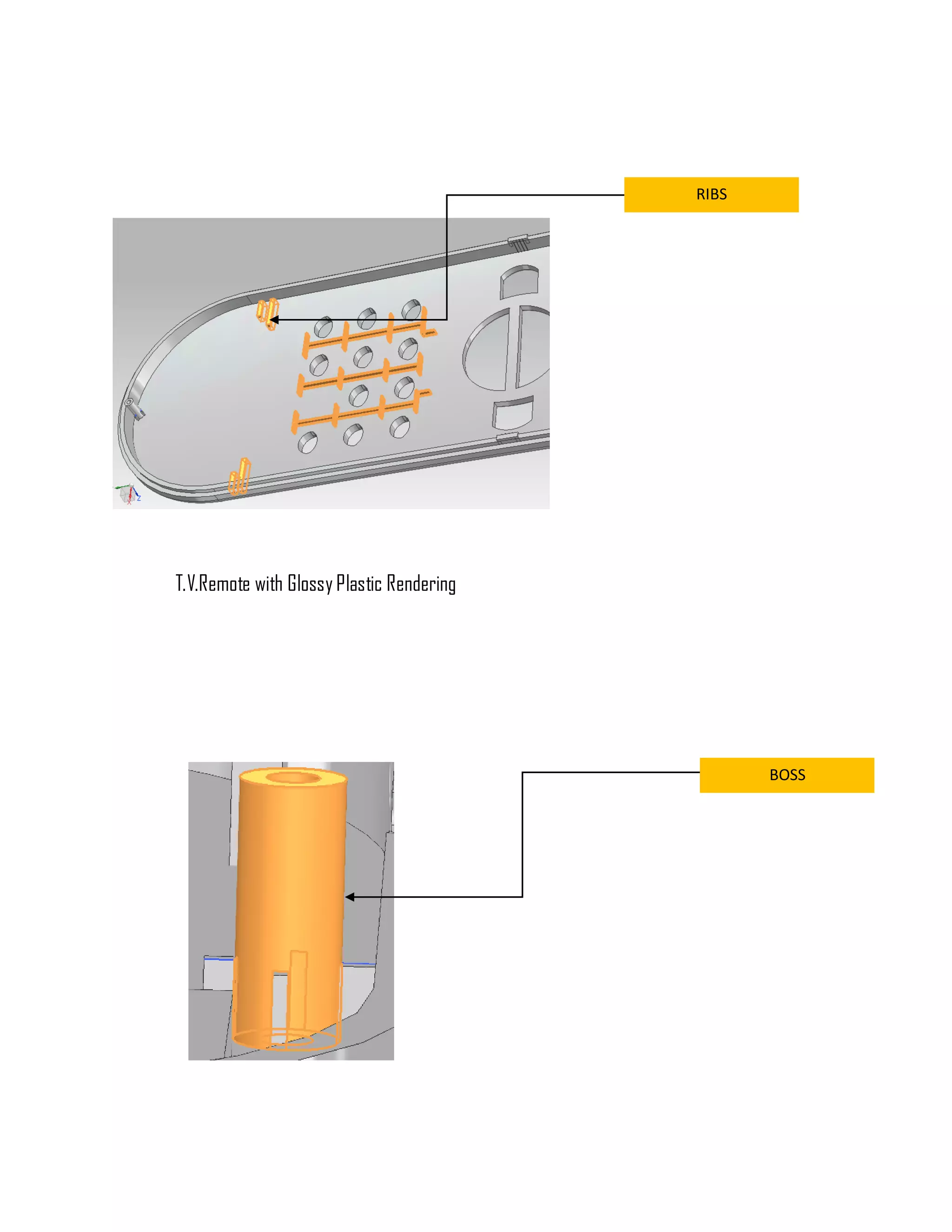

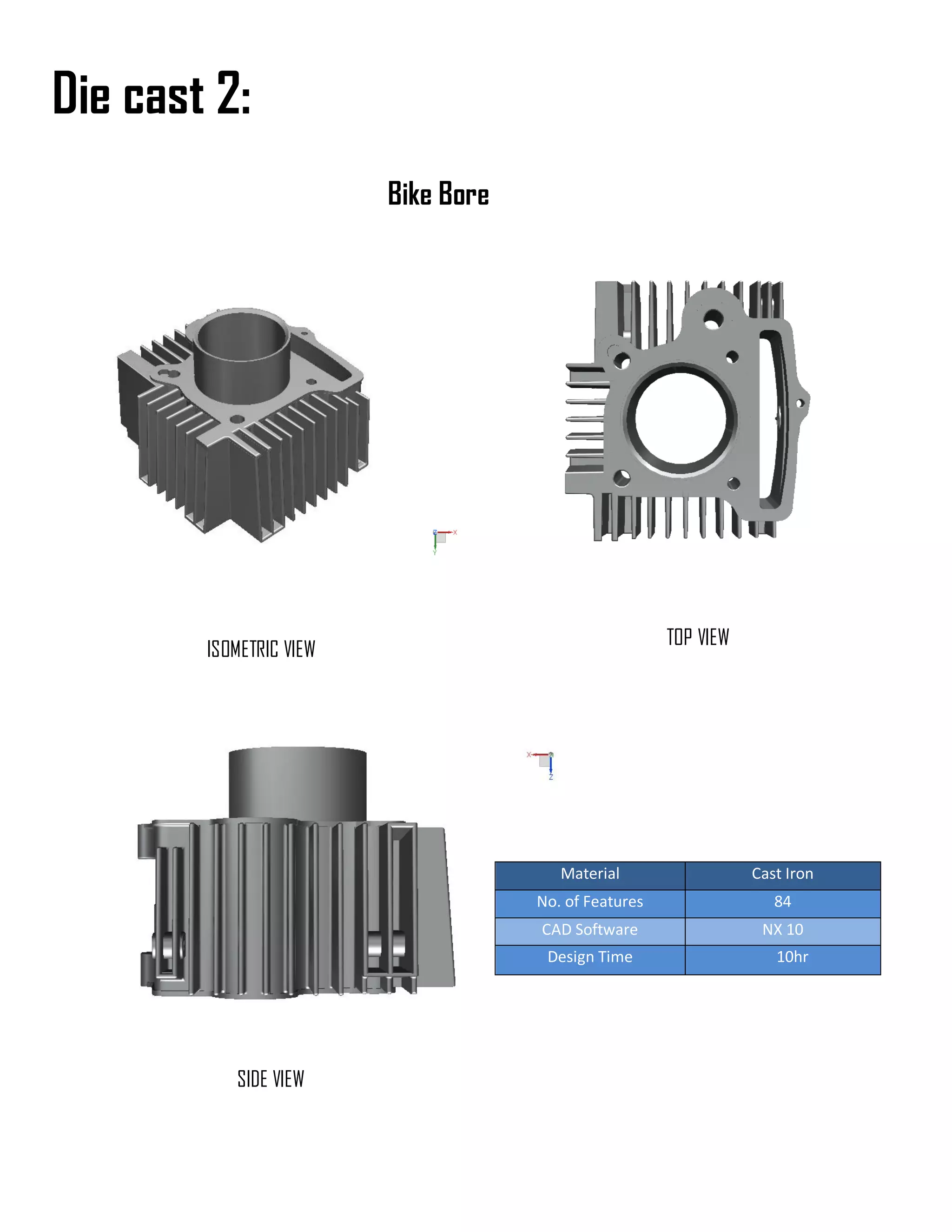

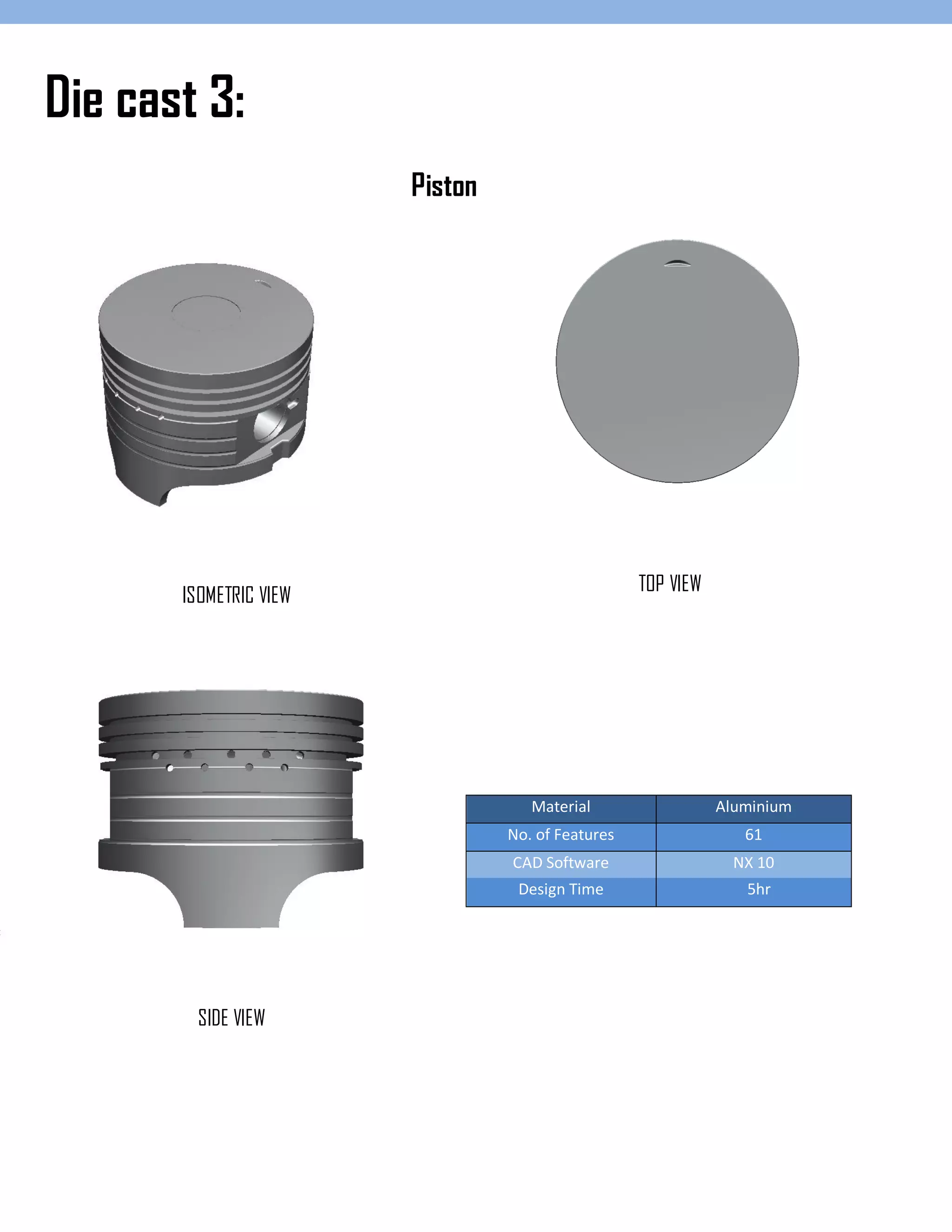

This document is a resume for Nagaraja Shenoy, a mechanical engineer from Mangalore, India. He has a passion for product design engineering and is self-motivated, dedicated, and a problem solver. He has an engineering degree and skills in CAD modeling, die casting and plastic design. He is looking for an internship or job in the automotive industry to gain experience and contribute his knowledge. The resume provides details on his education qualifications, projects, internship experience, skills, and sample work including sketches, part designs, and renders.