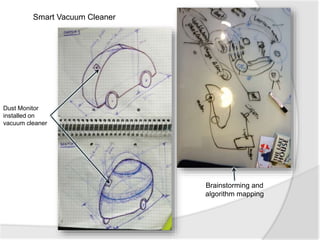

The document describes a dust monitoring project aimed at notifying households when to clean. A team developed a novel dust sensor that measures concentrations without becoming covered in dust over long periods. When dust levels exceed a threshold, the monitor alerts users and triggers a smart vacuum to start cleaning. The monitor was tested for 5 months, successfully measuring dust levels without sensor damage.