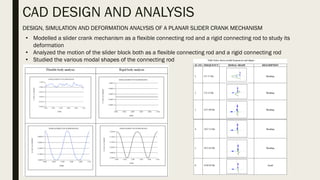

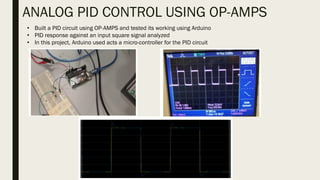

Vijay Anand Velmurugan is a graduate student in Mechanical Engineering at UIC specializing in Mechanical Design and Mechatronics. He has 2.5 years of experience as a design engineer at Volvo Group handling projects from concept to production. He has a proven track record of managing diverse, global projects for Volvo trucks. His portfolio highlights experience in product design and development, CAD software, finite element analysis, and cost improvement programs.