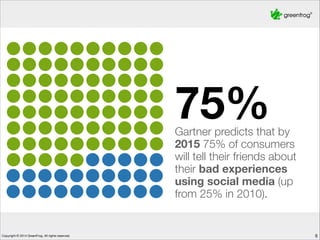

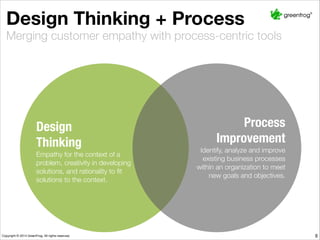

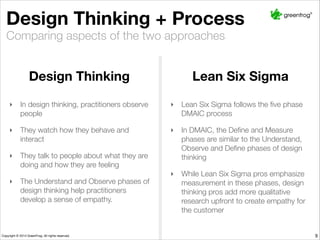

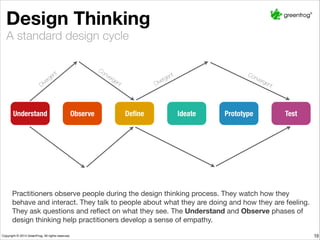

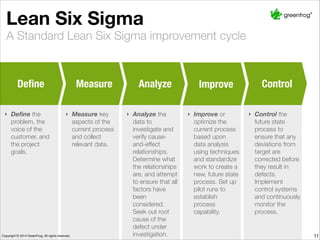

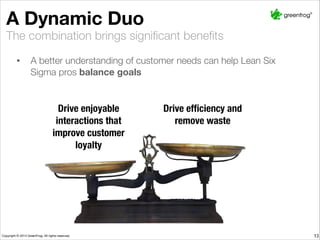

The document discusses how process improvement techniques are combining traditional Lean Six Sigma methods with design thinking. It argues that design thinking can help address gaps in Lean Six Sigma by developing deeper empathy for customer needs through techniques like observation. The document outlines how the Define and Measure phases of Lean Six Sigma's DMAIC model are similar to the Understand, Observe and Define phases of design thinking. It concludes that combining Process Improvement with Design Thinking provides benefits like driving customer loyalty while also improving efficiency, and that this trend of merging the two approaches will continue gaining momentum.