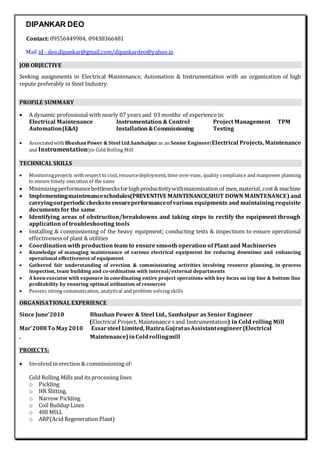

This document contains a summary of Dipankar Deo's professional experience and qualifications. He has over 7 years of experience in electrical maintenance, automation, instrumentation and project management, particularly in the steel industry. He is currently seeking a position utilizing these skills, preferably again in the steel industry. His previous role was as a Senior Engineer at Bhushan Power & Steel Ltd, where he oversaw electrical projects, maintenance and instrumentation in a Cold Rolling Mill.