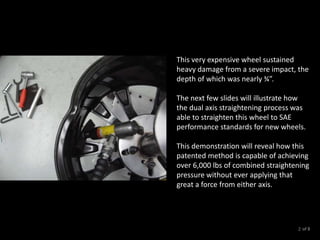

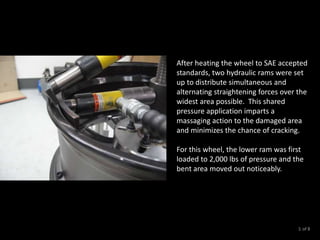

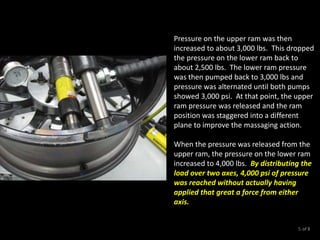

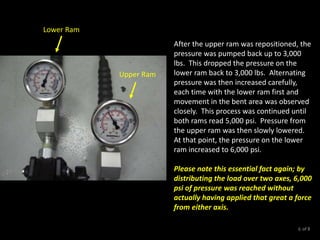

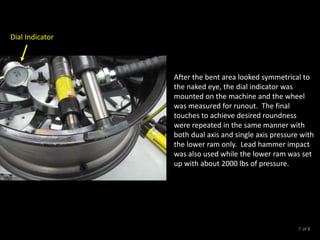

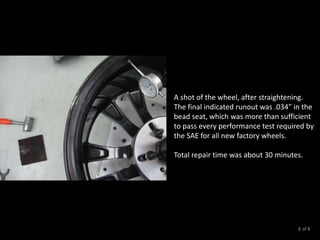

The document summarizes the NewArcTM patented dual axis wheel straightening process. It involves applying alternating straightening forces from two hydraulic rams to the wheel in a massaging action, allowing over 6,000 lbs of combined pressure to be applied without exceeding 2,000 lbs from each ram individually. This process straightens wheels with heavy damage in about 30 minutes while being less stressful on the wheel compared to other straightening methods.