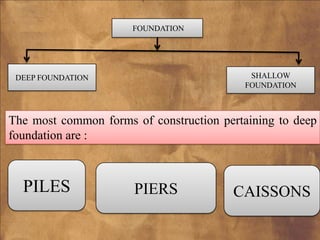

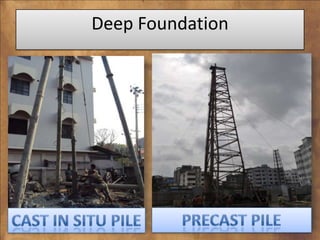

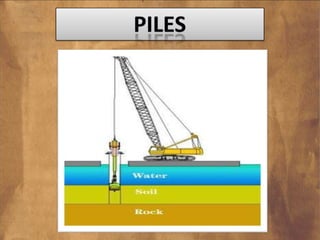

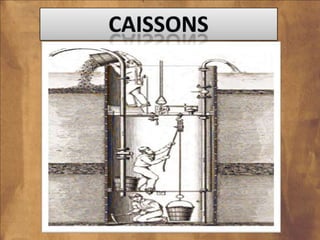

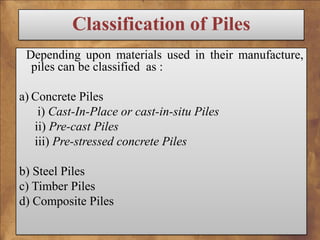

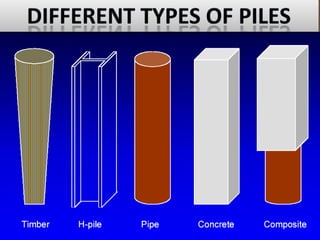

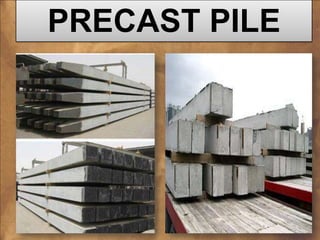

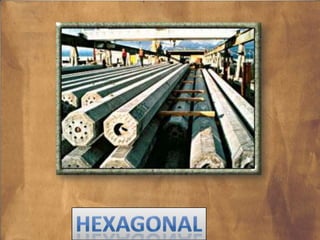

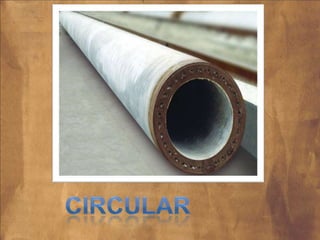

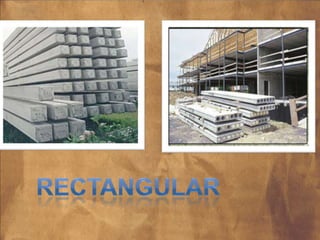

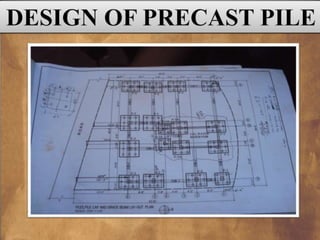

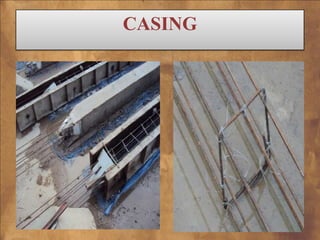

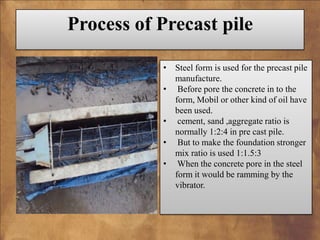

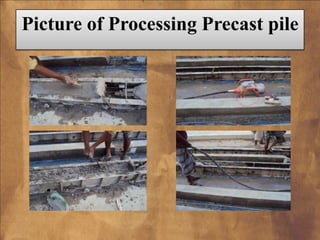

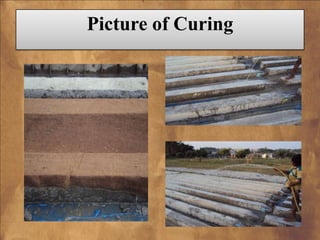

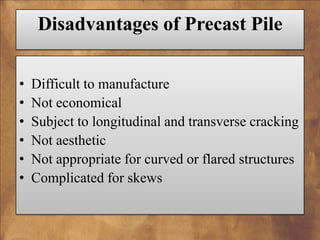

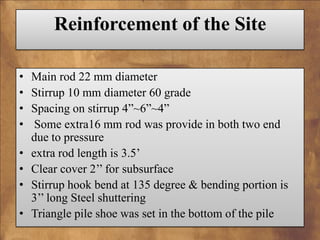

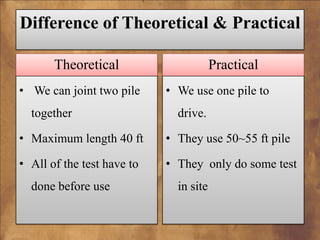

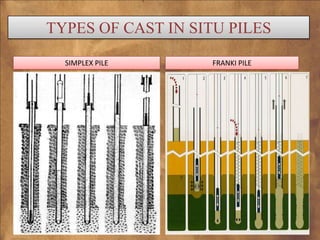

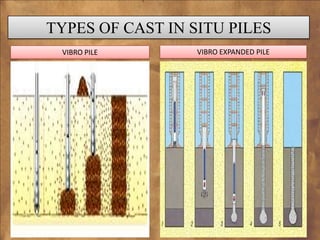

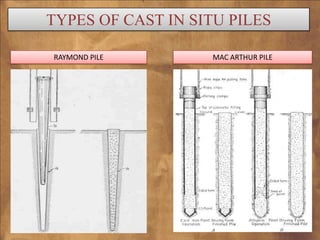

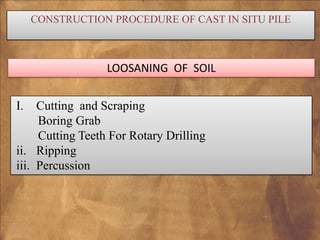

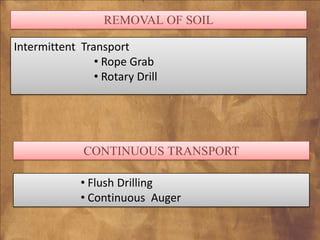

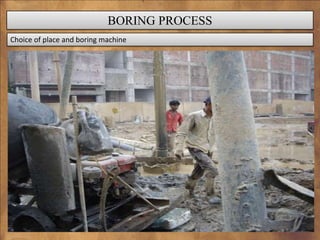

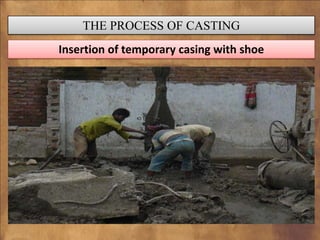

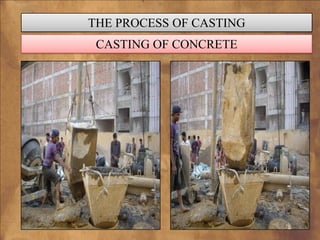

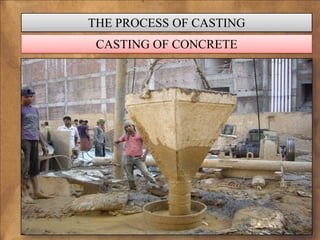

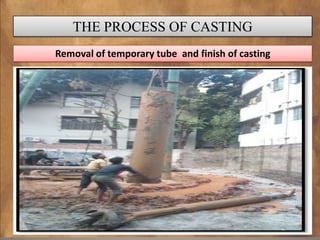

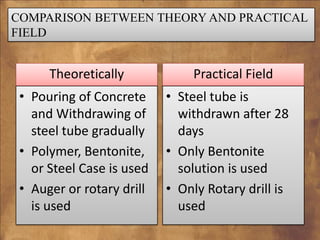

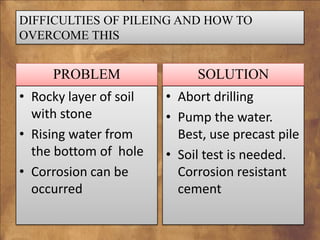

The document discusses the principles and various types of foundations, focusing on deep foundations like precast and cast-in-situ piles. It explains the manufacturing processes, advantages, and disadvantages of each type, as well as construction techniques and soil suitability. Additionally, it highlights the importance of proper design and soil testing in foundation engineering.