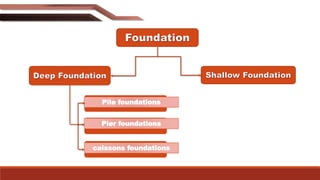

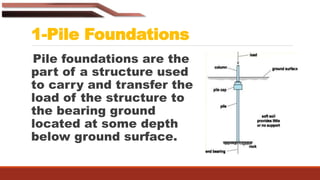

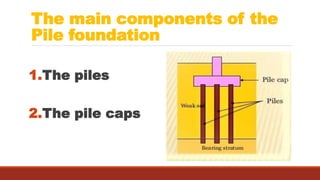

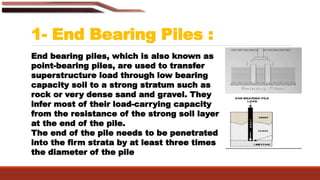

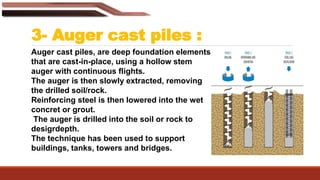

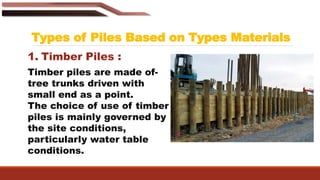

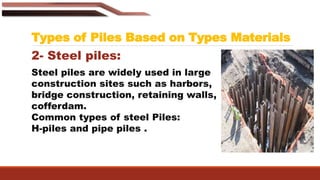

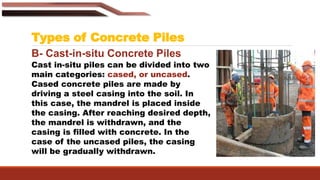

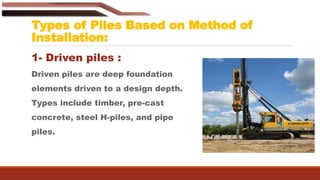

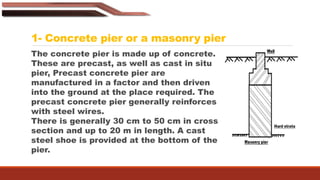

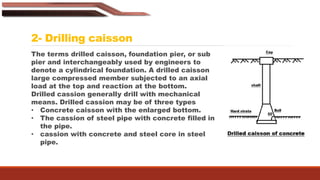

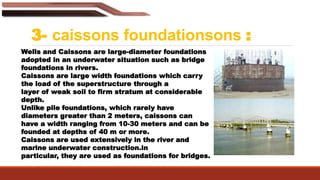

This document provides information on different types of deep foundations, including pile foundations, pier foundations, and caisson foundations. It discusses the key components and types of pile foundations based on function, material, and installation method. The main types of piles are end bearing piles, skin friction piles, and auger cast piles. Piles can also be classified based on material as timber piles, steel piles, concrete piles, or composite piles. The two primary installation methods are driven piles and bored piles. Pier foundations and caisson foundations are also summarized, including different types of caissons.