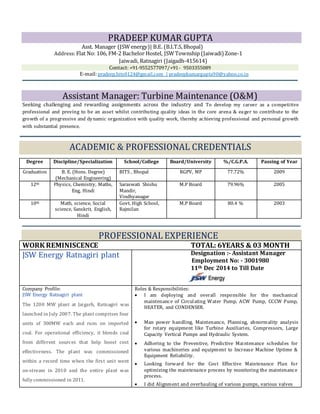

Pradeep Kumar Gupta is an Assistant Manager at JSW Energy in Ratnagiri, India. He has over 6 years of experience in turbine maintenance and mechanical maintenance roles. He holds a B.E. in Mechanical Engineering from BITS, Bhopal. Prior to his current role, he worked as a Senior Engineer at Adani Power Ltd in Gujarat and as a GET at Uttam Galva Steel Ltd in Khopoli. In his current role, his responsibilities include maintenance of pumps, heaters, condensers and other equipment. He focuses on preventative maintenance, cost optimization, and safety.