The document outlines various management styles and theories, emphasizing participation at all levels and the relationship between employee productivity and supervision. It discusses safety management principles, including accident causation theories and statistical analysis techniques to improve safety outcomes. Additionally, it covers statistical sampling and probability calculations relevant to management practices.

![HEINRICH

• Father of modern safety

• 1st textbook on safety

• Domino Theory of

Accident Causation(5

events): social, fault, unsafe

act, accident, injury

• 3 “E’s” of safety:

Engineering, Education, Enforcement

• 88 (unsafe acts)/10 (unsafe

conditions) /2 % (Acts of God)

• 4 steps of accident

prevention

• 4:1 ($ spent indirect vs direct)

• Pyramid [NM (300), Minor Event

(29), Major Events (1)]

MJE

MNE

Near Miss](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-4-2048.jpg)

![Probability of Success

• Question: An airplane has two engines, each

with a probability of success of 0.90. What is the

probability that the airplane will arrive safely if

one or both engines working will ensure a safe

arrival?

– Both engines working means “and” therefore multiply

• Pf = 1- Ps = 1- 0.9 = 0.1

• Ps = 1- [(0.1)(0.1)] = 0.99 Ps + Pf = 1](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-30-2048.jpg)

![Probability of Success

• Question: A widget is made of three components called

wiglets. Wiglet “A” has a Ps of .30, wiglet “B” has a Ps of

.45 and wiglet “C” has Ps of .60. Calculate Ps if wiglets B

and C are functionally parallel and wiglet “A” is in series.

– Calculate Ps of (B+C)

• Ps(B+C) = 1 – Pf

• Ps(B+C) = 1- [(.55)(.40)] = .78

– Calculate Ps of A(B+C)

• Ps = (.30)(.78) = .23

B

C

A

.30

.45

.60](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-32-2048.jpg)

![Probability Calculation

– 1.) Set up diagram

– 2.) Get individual Rates

a. Combo of 2 men

b. Combo of 2 women

c. Combo of 2 men and 2

women

– 3.) Calculate probability

Solution:

1. [6/2]*[4/2]**/[10/4]

2a. 6 nCR 2 = 15

2b. 4 nCR 2 = 6

2c. 10 nCR 4 = 210

3. [15][6]/[210] = 0.43

*Female, **Male

•Question: What is the probability that 2 men and 2 women will be

selected out of a group of 10 with 6 men and 4 women?](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-34-2048.jpg)

![Present Value of Money

• One trip to the bank:

• Many payments/trips to the bank:

P = F(1 + i)-n

where F is future value

P = A [(1+i)-n/i(1+i)n]

where A is amount of monthly payment

and n is # of time periods](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-48-2048.jpg)

![Present Value of Money

• Question:

– What is better deal, 1M over term or $3K

monthly?

• Answer:

– for 1M investment up front:

– for $3K monthly:

P = F(1+i)-n

Where F = 1M, i = interest rate and n= periods (eg/25)

P = A[(1+i)n - 1/i(1+i)n]

where A = periodic payments (eg/ $3K) and i = monthly interest (/12)](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-49-2048.jpg)

![PRESENT/FUTURE VALUE OF $

• Question: You need to purchase a new machine. Two options: (1) lease a machine for 10 years @ $2K/yr; or, (2)

purchase the machine for $10K with a maintenance agreement of $500/yr. After 10 yrs you can sell the machine

for a salvage value of $5K. Interest will be 15% for 10 yrs. Which option is best?

– Option 1 - Lease (PV regular payments):

• P = (2K)[(1+.15)10-1/(1.5)(1+.15)10] = 3.05/.607 (2K) = $10,038

– Option 2 - Buy (PV lump sum):

• (a) Calculate Maintenance Costs = $10,038 x (500/2000)* = 2509

• (b) Initial cost plus maintenance = 10K + 2509 = $12,509

• © calculate salvage: P = F(1+i)-n = (5K)(1.15)-10 = $1236

• © Cost minus salvage = 12509 - 1236 = $11,273

• *maintenance agreement is 1/4 of original monthly lease amount

– Option 1 is better as $10,038 < $11,273

P = A[(1+i)n-1/i(1+i)n]

P = F(1+i)-n](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-51-2048.jpg)

![PRESENT/FUTURE VALUE OF $

• Question: The initial cost of a safety project will be $15K.

The project will cost $2K/yr to maintain, but will save

$4K/yr over 6 yrs @ 7%. Should the company invest in

the startup?

– (a) Calculate PV of maintenance cost: $9533

– (b) Add maintenance cost to project cost: 15K + 9533 = $24,533

– © Calculate PV of savings: use eqn (a) substituting 4K = $19,066

– © Cost is > than Savings

P = A[(1+i)n-1/i(1+i)n]](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-52-2048.jpg)

![CALCULATING [UNK]

• Question: 1-L of benzene breaks and evaporates in a 20x20x10m closed room

at NTP. If the MW is 78 and the sg is .6, what is the concentration?

• Calculate mg:

– 1L of benzene = 600 g (60% of L of H20 is 1)

– 600g x 1000mg/g = 600K mg

• Calculate area: 4000 m3

• Calculate ppm: (600Kmg/4000m3)(24.45)/78 = 47 ppm

ppm = mg/m3 x 24.45/ MW](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-66-2048.jpg)

![REDUCING CONCENTRATIONS

• Question: A furniture drying area contains 100 ppm of a solvent. If the volume of

the room is 100Kft3, the ventilation rate 2,000 cfm, how long to reduce the [solvent]

to 25 ppm?

– Where C1 is initial [ ]

– C2 is final [ ]

– Q’ is ventilation rate in cfm

– V is volume of room in ft3

– t1 is start time

– t2 is end time

• Looking for t2:

• t2 = ln(C2/C1)(V/Q’)

• t2= ln (.25)(100Kft3)/(-2000ft3/min) = 69.31 min

ln(C2/C1) = -Q’/V(t2-t1)](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-67-2048.jpg)

![SAMPLING SAEs

• Question: A sample reveals xylene exposure for an 8-hr period was 105 ppm. The

PEL for xylene is 100 ppm. The SAE is 0.10. What can you conclude from these

results?

– Where Y = standardized [ ]

– X = given concentration

– CL = confidence limits

• Y = X/PEL = 105/100 = 1.05

• UCL = Y + SAE = 1.05 + 0.1 = 1.15

• LCL = Y - SAE = 1.05 - 0.1 = .95

• Therefore a possible overexposure exists because UCL> 1 and LCL < 1.

Y = X/PEL

UCL = Y + SAE

LCL = Y - SAE](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-68-2048.jpg)

![Electrical Classifications (NEC 500)

• Class I:

– Div. 1:ignitable [flam. Gases and vapors] normally exist, (eg/open systems)

– Div. 2: volatile liquids or gases confined

• Class II:

– Div. 1: comb. dust under normal conditions

– Div. 2: sufficient qty of dust not normally present

• Class III:

– Div. 1: ignitable fibers are handled and/or processed

– Div. 2: ignitable fibers are handled only](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-87-2048.jpg)

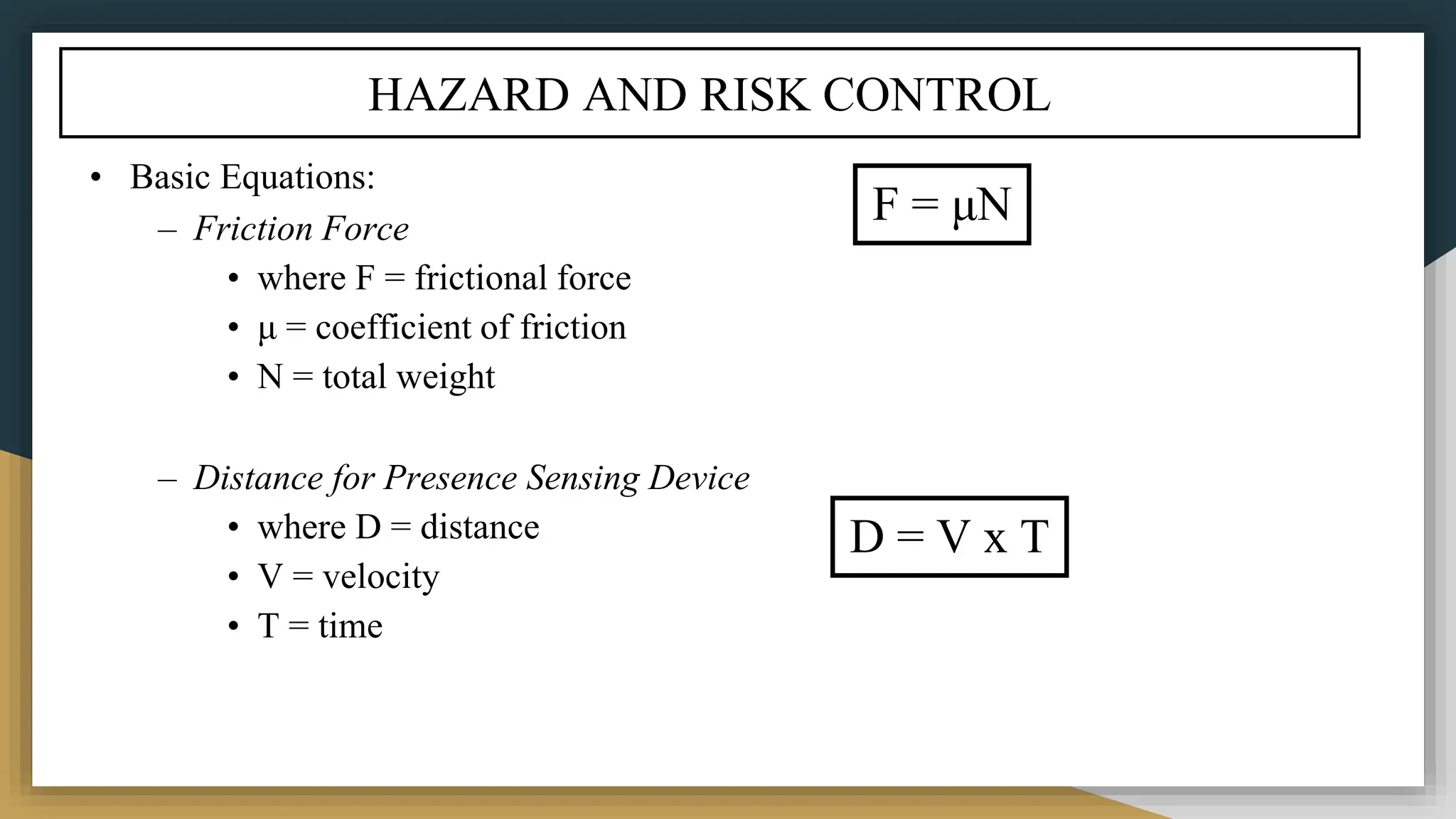

![HAZARD AND RISK CONTROL

• Breaking Strength:

– where B is rope breaking strength

– S = # of parts of sheaves in rope

– W = weight

– F = Safety Factor B = [W + 0.1WS/S]F](https://image.slidesharecdn.com/cspstudynotes-240623190953-61b47398/75/CSP-Study-Notes-2024-PAUL-Mcneill-CSP-117-2048.jpg)